Universal water enamel

A water-based and enamel technology, applied in coatings, epoxy resin coatings, etc., can solve problems such as lack of access to users, and achieve the effects of easy construction, improved adhesion, flexibility, and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

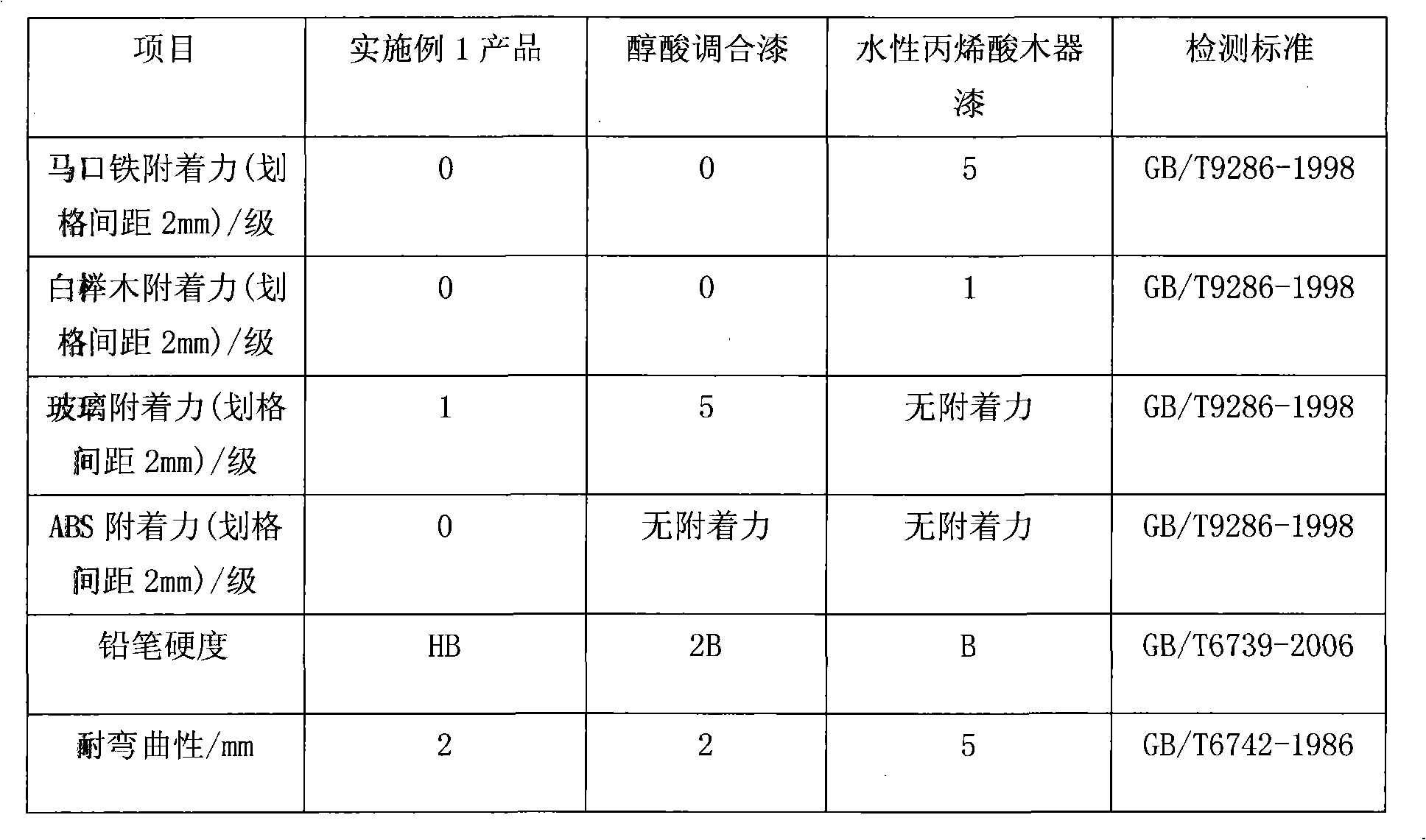

Embodiment 1

[0048] A kind of water-based universal enamel (varnish), comprises following components, and the percentage by weight of each component is: organosilicon modified water-based acrylic resin: 58%, acrylic acid modified water-based epoxy ester resin: 10%, nanoscale talcum powder: 3.8%; adhesion promoter: 0.8%; coalescent: 4%; anti-flash rust agent: 1.2%; dispersant: 0.4%; leveling agent: 0.2%; : 0.5%; fungicide: 0.3%; PH regulator: 0.2%; thickener: 1.5%, water: 18.8%.

[0049] Follow the steps below to prepare:

[0050] 1) Put the above-mentioned dispersant, wetting agent, water and 50% defoamer into a high-speed stirring container with a rotation speed of 1300 rpm, and add a thickener while stirring at a high speed until the thickener is completely dispersed Finally, add nano-talc powder and disperse at a high speed until the fineness of the scraper is below 20 microns;

[0051] 2) Pour the dispersed liquid in step 1) into the tank of the quick defoaming device. After defoamin...

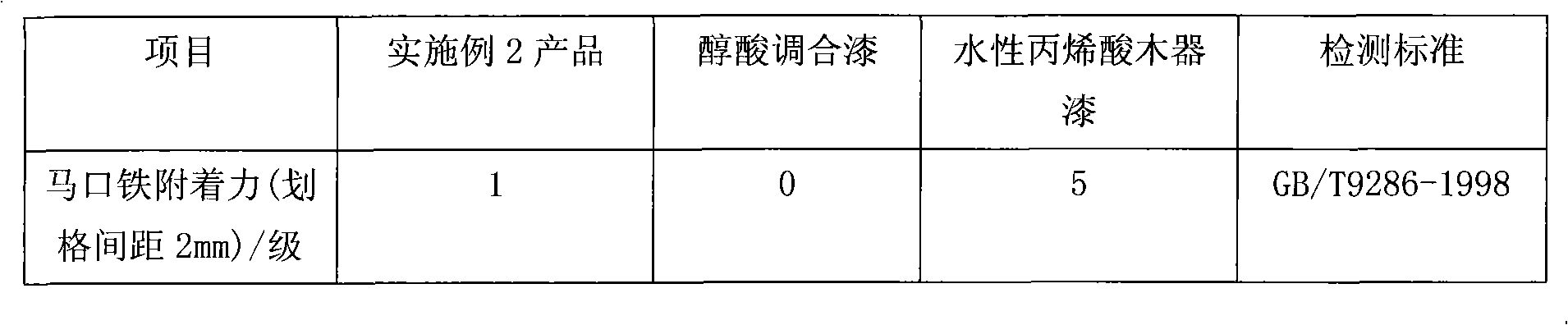

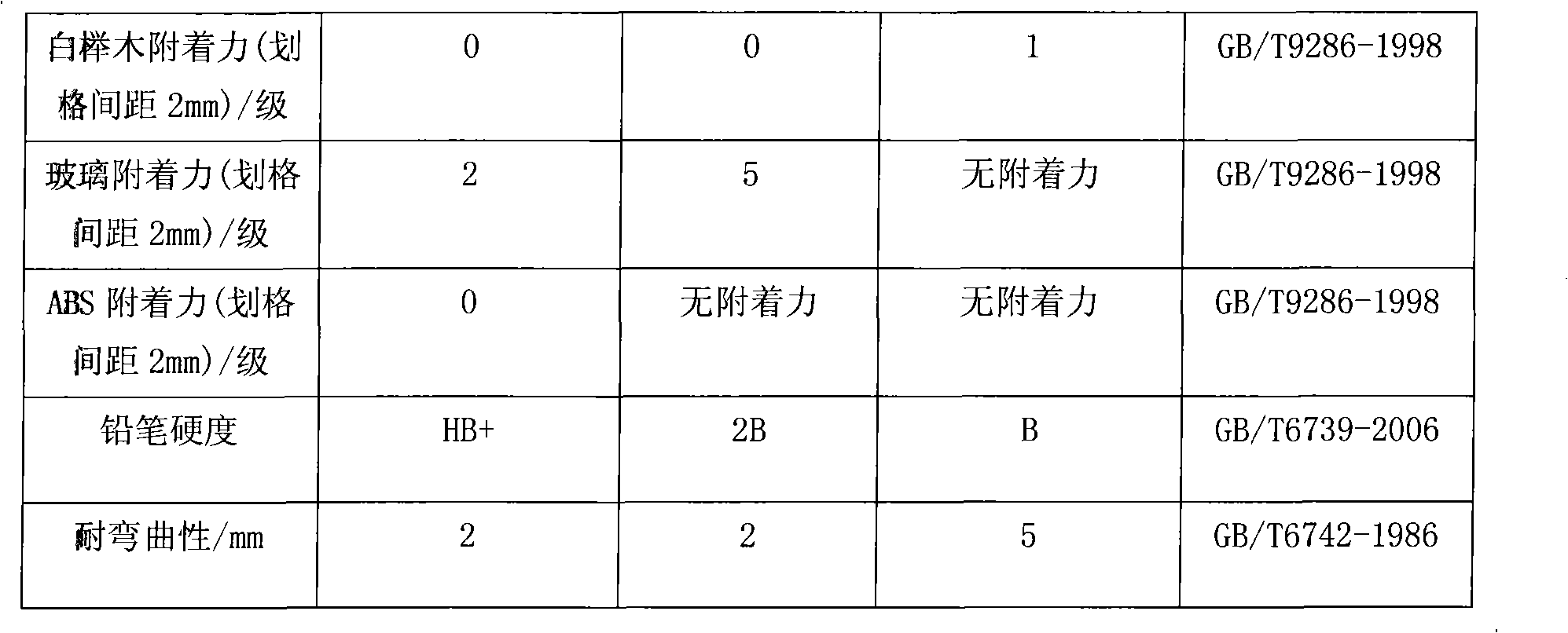

Embodiment 2

[0056] A kind of water-based universal enamel (varnish), comprises following components, and the percentage by weight of each component is: organosilicon-modified water-based acrylic resin: 62%, acrylic acid-modified water-based epoxy resin: 8%, nanoscale talcum powder: 3.6%; adhesion promoter: 0.4%; coalescent: 4%; anti-flash rust agent: 1%; dispersant: 0.3%; leveling agent: 0.3%; wetting agent: 0.3%; defoamer : 0.4%; fungicide: 0.2%; PH regulator: 0.3%; thickener: 1.6%, water: 17.6%.

[0057] Follow the steps below to prepare:

[0058]1) Put the above-mentioned dispersant, wetting agent, water and 50% defoamer into a high-speed stirring container with a rotation speed of 1500 rpm, and add a thickener while stirring at a high speed until the thickener is completely dispersed Finally, add nano-talc powder and disperse at a high speed until the fineness of the scraper is below 20 microns;

[0059] 2) Pour the dispersed liquid in step 1) into the tank of the quick defoaming de...

Embodiment 3

[0065] A water-based universal enamel paint (red paint), comprising the following components, the weight percent of each component is: silicone modified water-based acrylic resin: 49%, acrylic acid-modified water-based epoxy ester resin: 12%, nanoscale talcum powder : 4.5%; adhesion promoter: 1.0%; coalescent: 3.3%; anti-flash rust agent: 1.5%; dispersant: 0.6%; leveling agent: 0.3%; Agent: 0.6%; Fungicide: 0.3%; PH regulator: 0.3%; Thickener: 1.0%, Water: 17.1%; Scarlet water-based color paste: 8%.

[0066] Follow the steps below to prepare:

[0067] 1) Put the above-mentioned dispersant, wetting agent, water and 50% defoamer into a high-speed stirring container with a rotation speed of 1300 rpm, and add a thickener while stirring at a high speed until the thickener is completely dispersed Finally, add nano-talc powder and disperse at a high speed until the fineness of the scraper is below 20 microns;

[0068] 2) Pour the dispersed liquid in step 1) into the tank of the qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com