Box type drying device for drying triazole after washing

A box-type drying and triazole technology, which is applied in drying gas arrangement, drying, drying machine and other directions, can solve the problems of large particles, too small energy consumption, insufficient drying of particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

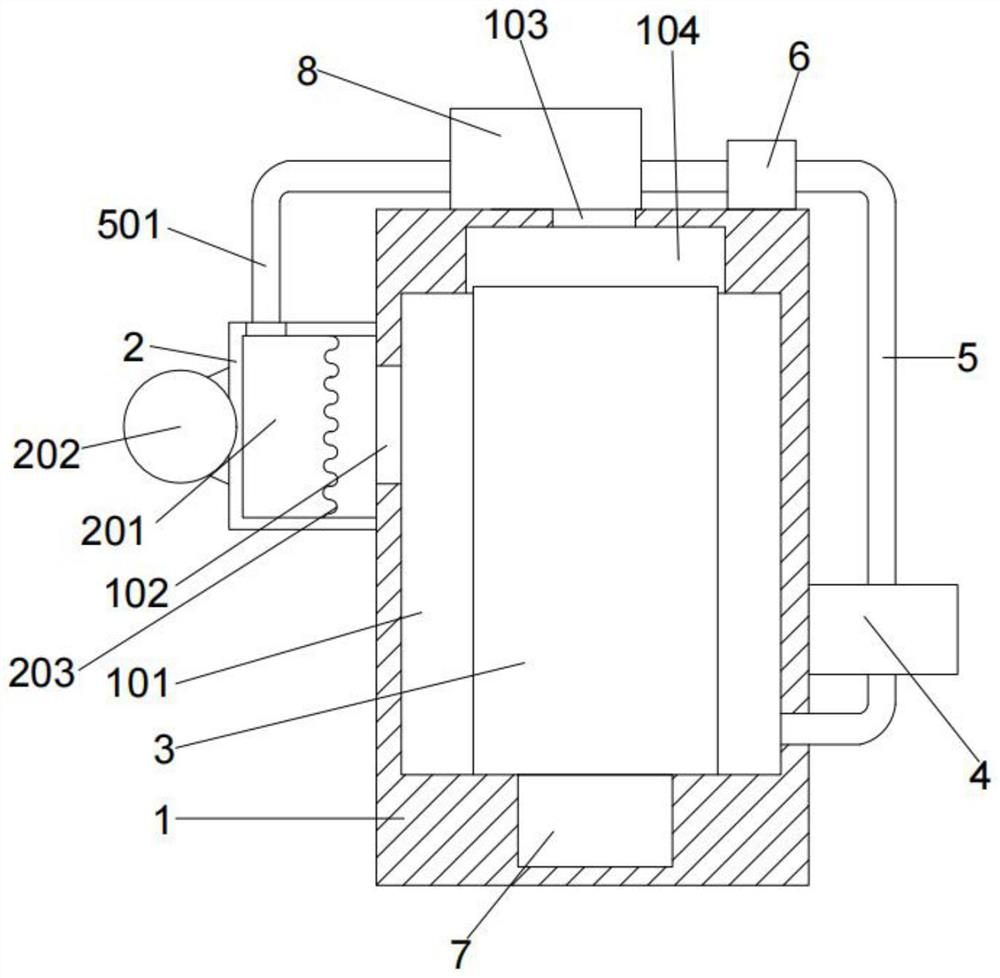

[0038] The embodiment of the present invention provides a box-type drying device for drying triazole after washing, such as Figure 1-2 As shown, it includes: a box 1, a drying chamber 101 is arranged inside the box 1, a drying box 3 is arranged inside the drying chamber 101, and one side of the drying chamber 101 is connected to a heat source device through an air inlet 102 , the side of the drying chamber 101 away from the air inlet 102 is connected with the circulation equipment 4 through the air outlet 1, and the circulation equipment 4 is connected with the heat source equipment through the connecting pipeline;

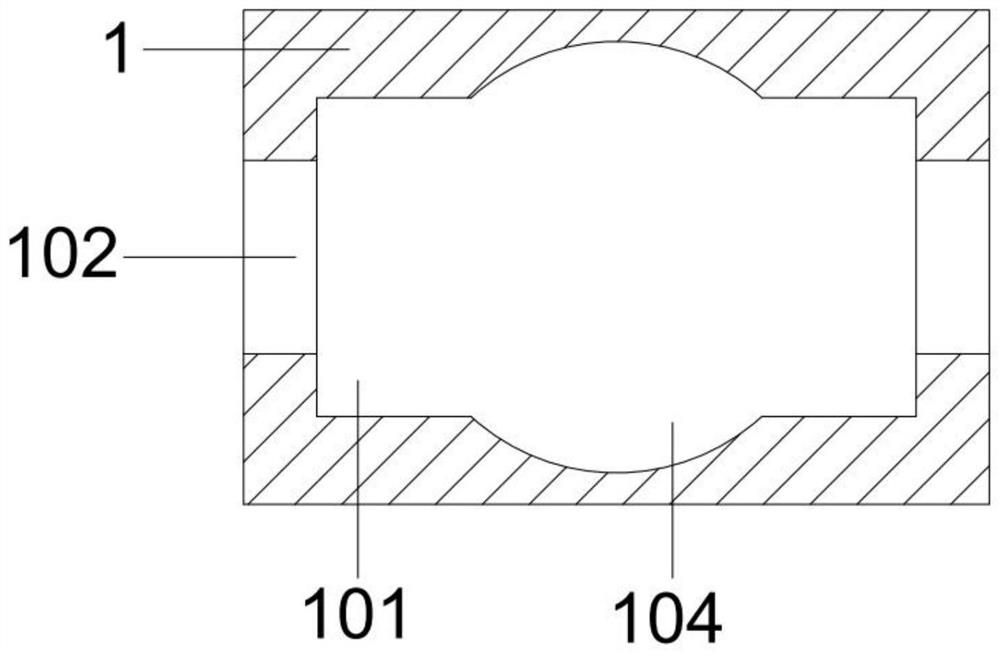

[0039] The air inlet 102 is arranged on the left side of the box body 1, the air outlet 1 is arranged on the right side of the box body 1, and the upper end of the box body 1 is provided with a feeding port 103. The material port 103 is communicated with the drying chamber 101;

[0040] An installation cavity 104 is arranged in the middle of the drying chamber 101...

Embodiment 2

[0046] On the basis of Example 1, as figure 1 As shown, the circulation device 4 includes a fan two 6 and a dehumidification device, the fan two 6 is a circulating fan, and the dehumidification device is an air dehumidifier;

[0047] The connecting pipeline includes an air outlet pipe 5 and an air inlet pipe 501. The air inlet of the air outlet pipe 5 is communicated with the air outlet of the drying chamber 101, and the air outlet of the air outlet pipe 5 is connected to the air outlet of the drying chamber 101. The air inlet 2 of the fan 26 is in communication, the air outlet 3 of the fan 2 6 is communicated with the air inlet 2 of the air inlet pipe 501, and the air outlet 2 of the air inlet pipe 501 is connected to the upper left side of the heat source shell 2. The opening on the side is connected, and the opening is connected with the heating chamber 201, and the dehumidification equipment is provided in the middle of the air outlet pipe 5;

[0048] The lower side of th...

Embodiment 3

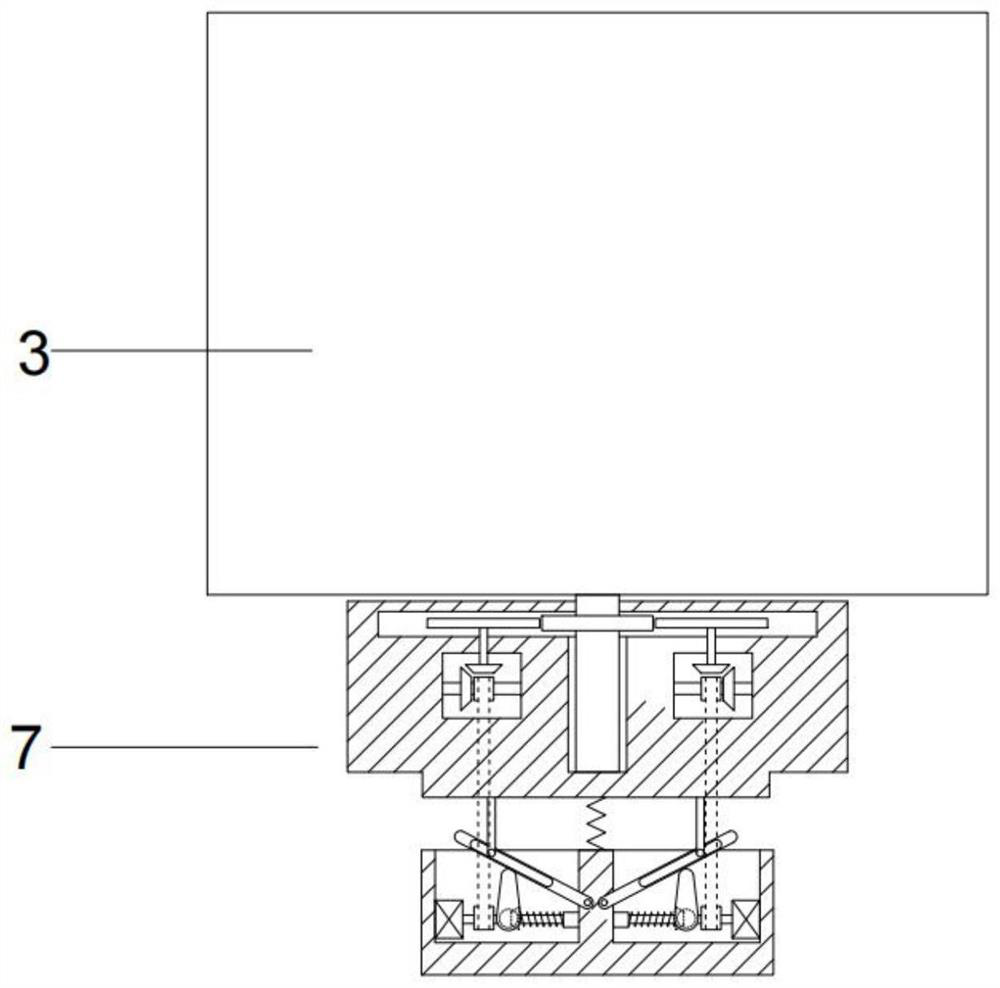

[0052] On the basis of Example 1, as Figure 3-4 As shown, the lower end of the drying chamber 101 is provided with an auxiliary drying mechanism 7, and the auxiliary drying mechanism 7 is fixedly connected with the lower end of the drying box 3. The auxiliary drying mechanism 7 includes:

[0053] The installation shell 703 is provided with a working cavity 1 701 and a working cavity 2 702 inside the installation shell 703. The working cavity 1 701 communicates with the working cavity 2 702. The inner left and right sides of the installation shell 703 are symmetrically provided with working cavity 701. cavity three 704;

[0054] Two rotating shafts 1 707, the two rotating shafts 1 707 are respectively rotatably arranged inside the working chamber 3 704 on the left and right sides, the rotating shaft 1 707 is fixedly connected with the bevel gear 1 714 and the pulley 1 721 ;

[0055] The second rotating shaft 719 is rotatably connected with the lower end of the drying box 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com