Rapid high-precision appearance quality detection system and detection method for reflective curved surface

A technology of appearance quality and detection system, which is applied in optical testing flaws/defects, measuring devices, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

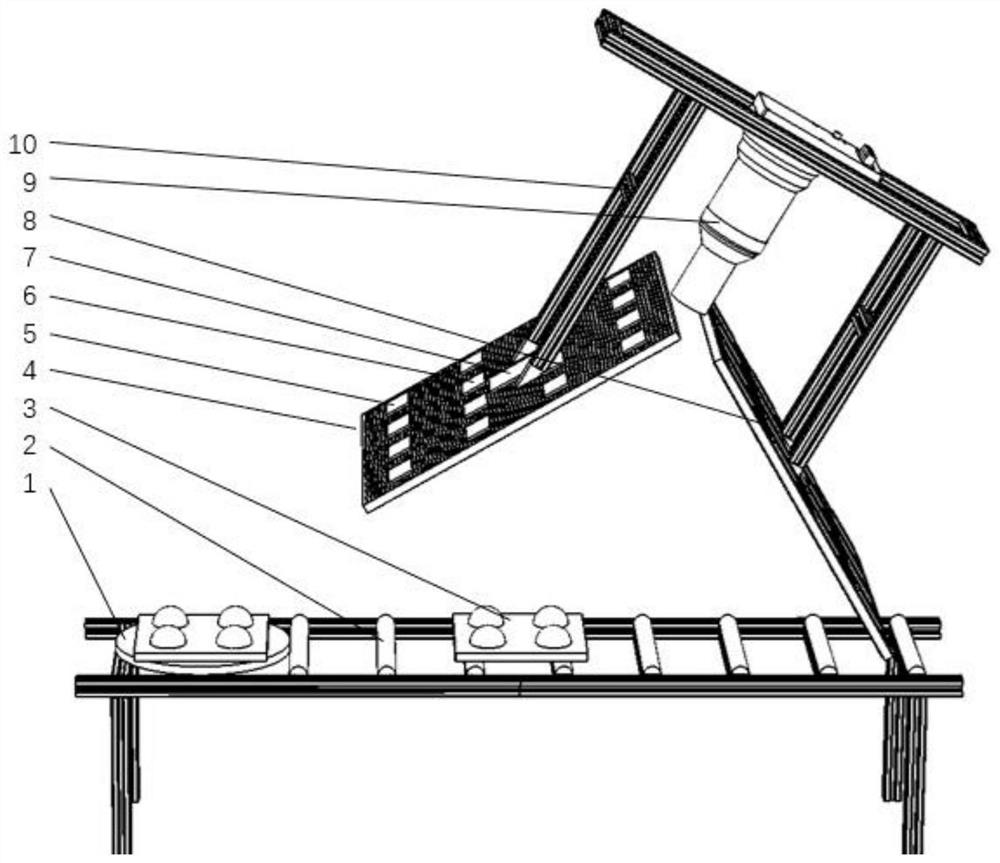

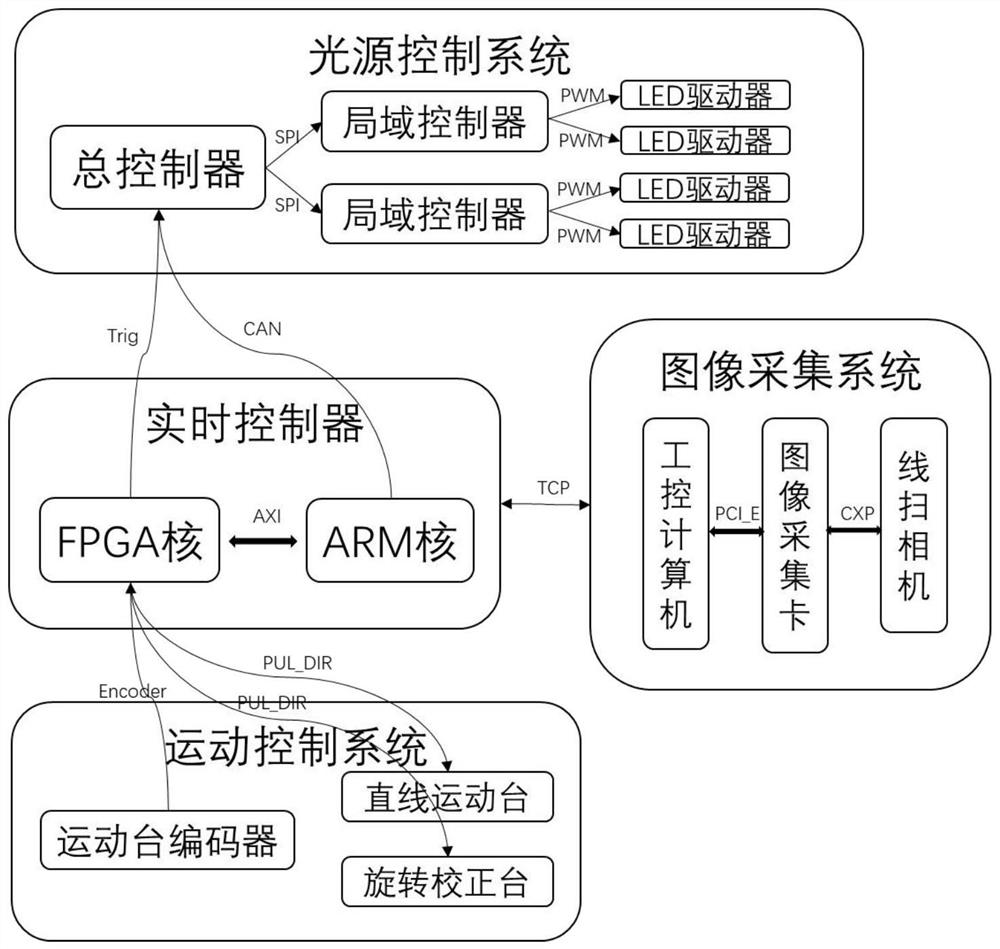

[0060] The detection station consists of a line-scan camera, FPGA control board, industrial computer, two light boards, and a servo motion table. There is a jig on the servo motion table, which can limit the sample to be tested and prevent it from moving. The control signal of the servo motion platform is output by the FPGA control board to make it move at a desired speed for a certain distance. At this time, the line scan camera starts to work to collect image information. In order to ensure the accuracy of sampling and detection speed, the FPGA control board will read the encoder signal on the servo motion table, and at the same time output it to the light source controller and the line trigger terminal of the line scan camera through electronic gears, electronic cams and other arithmetic units, so that Even if there is a slight disturbance in the movement speed of the moving table, it will not affect parameters such as exposure time and scanning time, avoiding problems such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com