Compressor blade crack fault detection method

A technology for compressor blades and fault detection, which is applied in neural learning methods, measuring devices, computer parts, etc., can solve problems such as affecting the accuracy of fault detection, prone to errors, and time-consuming, so as to achieve high-accuracy detection, improve Accuracy, the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

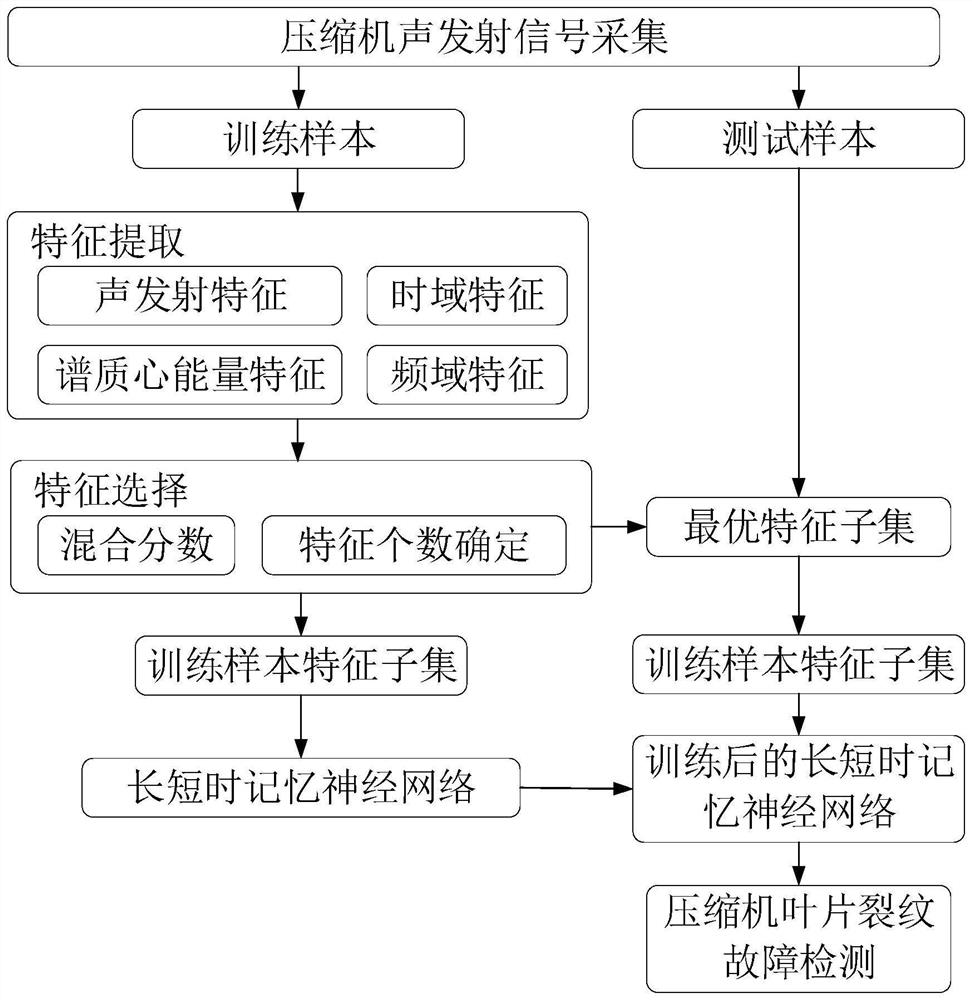

[0042] like figure 1 As shown, the compressor blade crack fault detection method according to the embodiment of the present invention includes the following steps:

[0043] Step 1: Collect two-channel acoustic emission signals at the compressor air outlet, and divide them into two-channel training samples and two-channel test samples;

[0044] Step 2: perform feature extraction on the two-channel training samples, including acoustic emission features, time-domain features, frequency-domain features, and spectral centroid energy migration features;

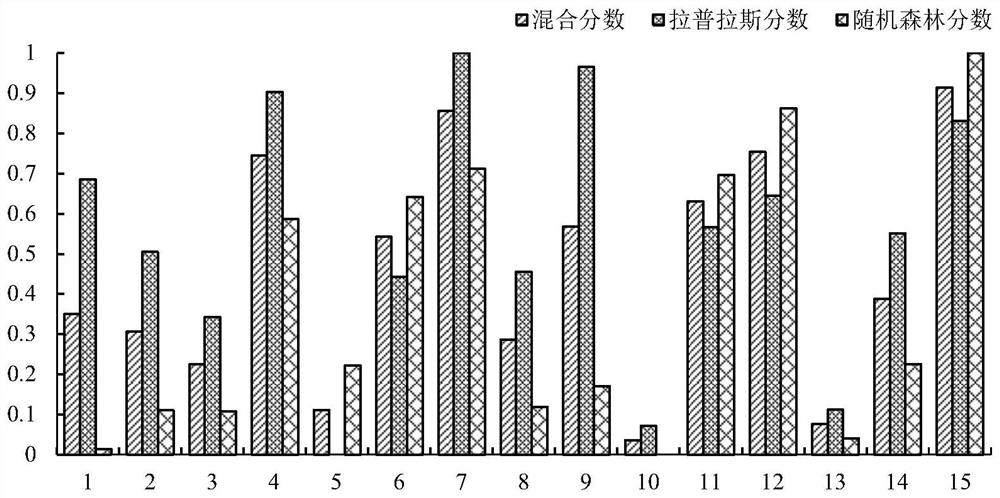

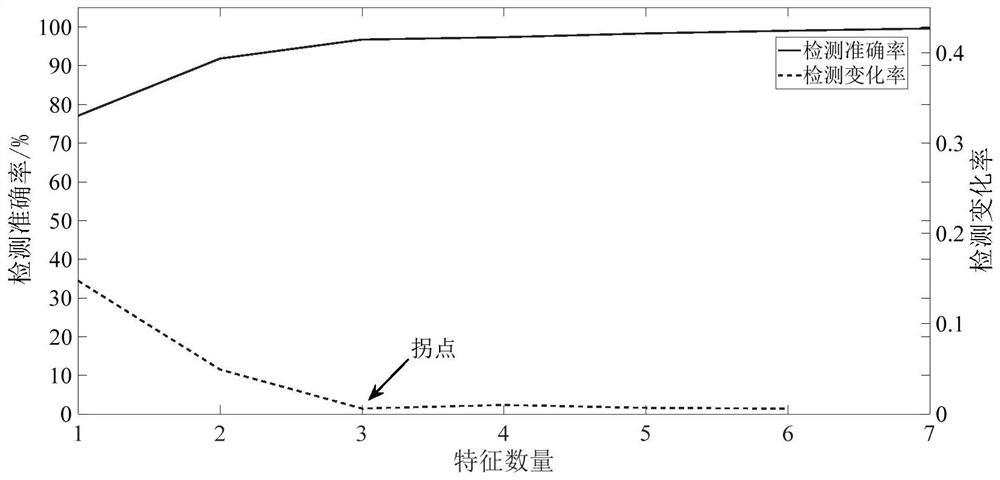

[0045] Step 3: Select features using a hybrid feature selection method to establish an optimal feature subset;

[0046] Step 4: Extract the features of the two-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com