High-heat-flux dual-channel heat dissipation system

A technology of high heat flux and heat dissipation system, applied in the field of high heat flux heat dissipation system, can solve the problems of poor fitability and large volume of heat dissipation system of high-power components, etc., to increase heat dissipation effect, reduce noise, and reduce radiator and the effect of the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

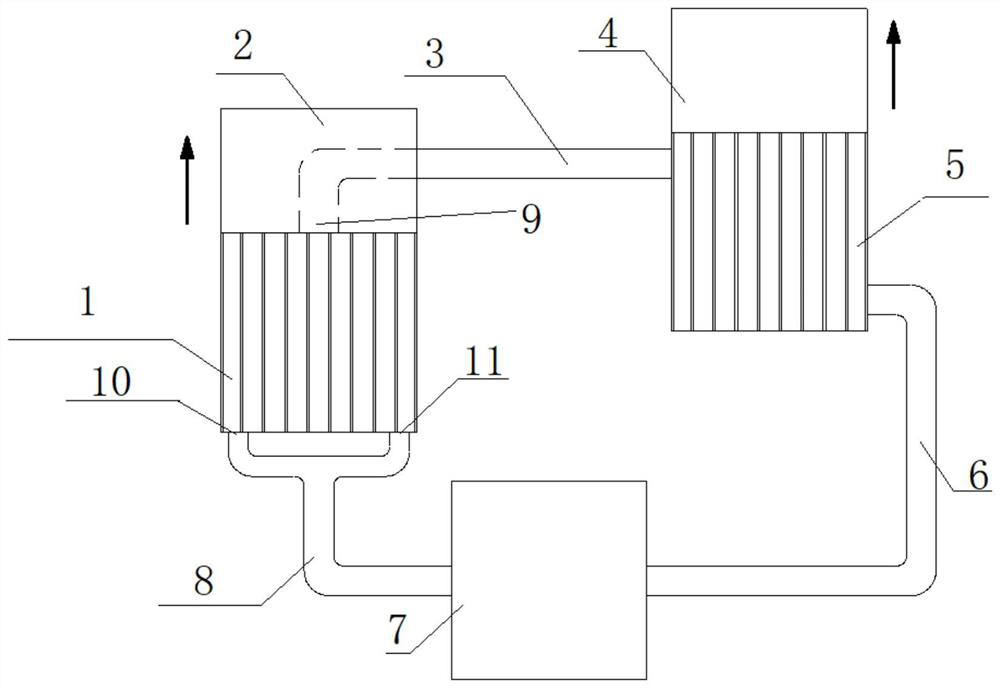

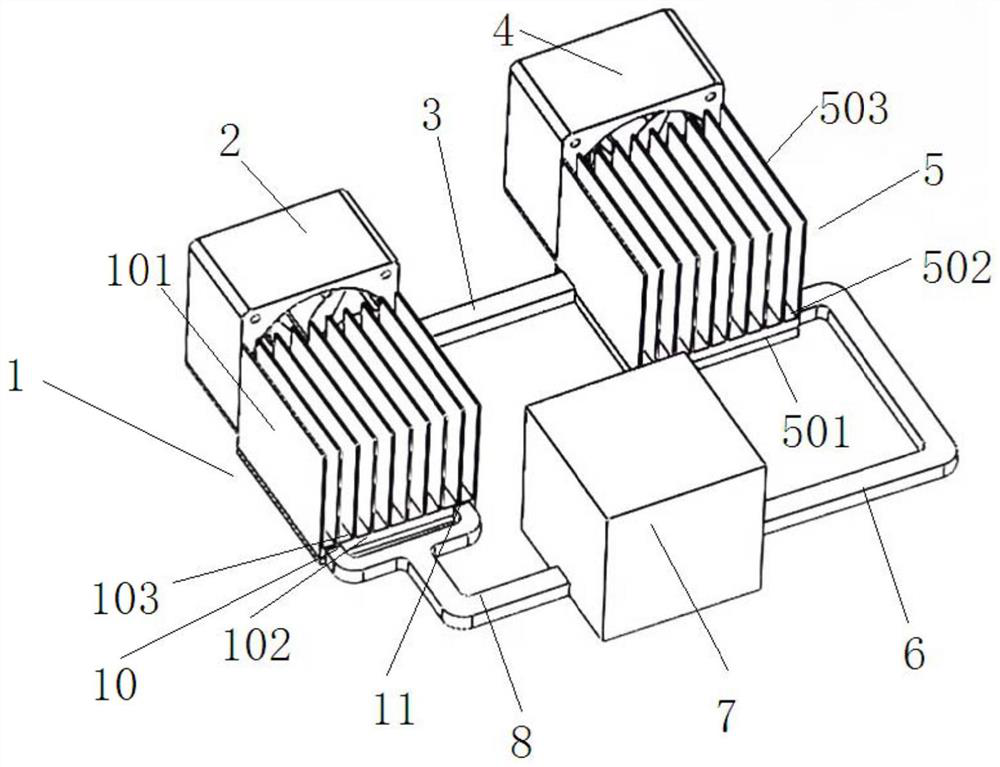

[0035] Example 1: Dual-channel heat dissipation system with high heat flux density, such as Figure 1~Figure 2 shown, including:

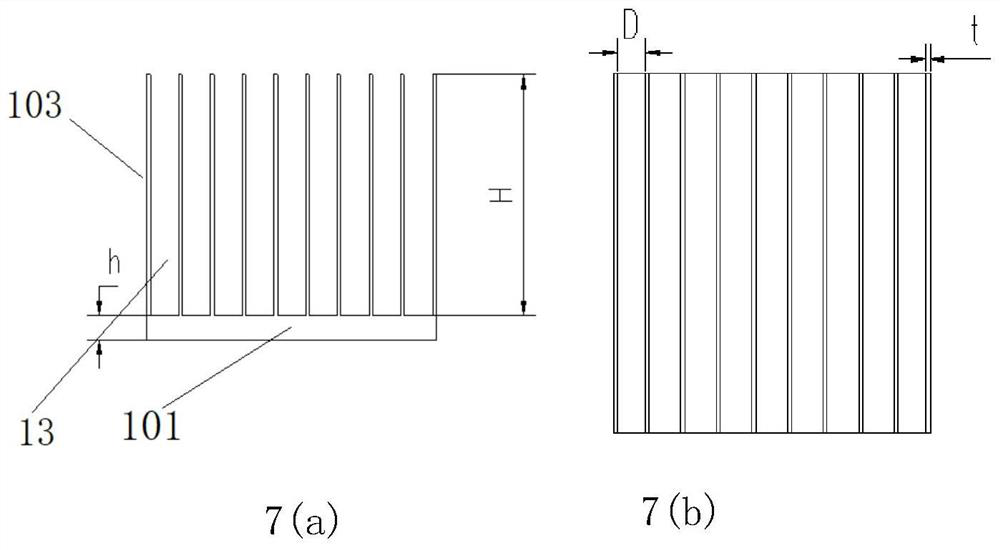

[0036] Radiator 1, heat exchanger 5 and pump 7; radiator 1 includes radiator casing 102 and radiator cover 103, heat exchanger 5 includes radiator casing 501 and heat exchanger cover 502, radiator cover A plurality of vertical and parallel radiator fins 101 are arranged on the 103, and a plurality of vertical and parallel heat exchanger fins 503 are arranged on the heat exchanger cover plate 502, and intervals are arranged between the fins, such as Figure 7 Interval 13 shown;

[0037] The surface of the radiator housing 501 is provided with a heat exchanger groove, and both ends of the heat exchanger groove are provided with an outlet and an inlet; the surface of the radiator housing 102 is provided with a double-channel groove, and two ends of the double-channel groove are respectively provided with one entrance and two exits;

[0038] The out...

Embodiment 2

[0064] Embodiment 2: On the basis of Embodiment 1, in the dual-channel heat dissipation system with high heat flux density provided in this embodiment, a plurality of vertical and staggered pin fins are arranged in the heat exchanger groove or the dual-channel groove. Filling the pin fins can enhance the heat dissipation of the cooling liquid, so that the heat distribution of the heat dissipation plate is uniform, and the temperature difference between each part is less than 5 °C, which greatly reduces the thermal stress and deformation caused by thermal stress. The material of the filled pin fins is the same as that of the heat dissipation case, and the cross-section of the pin fins can be diamond-shaped, jujube-shaped, rectangular, circular and oval. Among them, the comprehensive heat dissipation performance of rhombus and jujube core shape is better than that of rectangle and circle, so diamond and jujube core shape are preferred for filling pin-fin cross section. The secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com