Device and method for removing particulate matters in hydrochloric acid regeneration roasting flue gas

A technology of particulate matter and dust removal device, which is applied in the field of hydrochloric acid waste liquid regeneration treatment, can solve the problems of inability to increase dust removal equipment, increase equipment and operating costs, fluctuation of particle emission concentration, etc. Low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

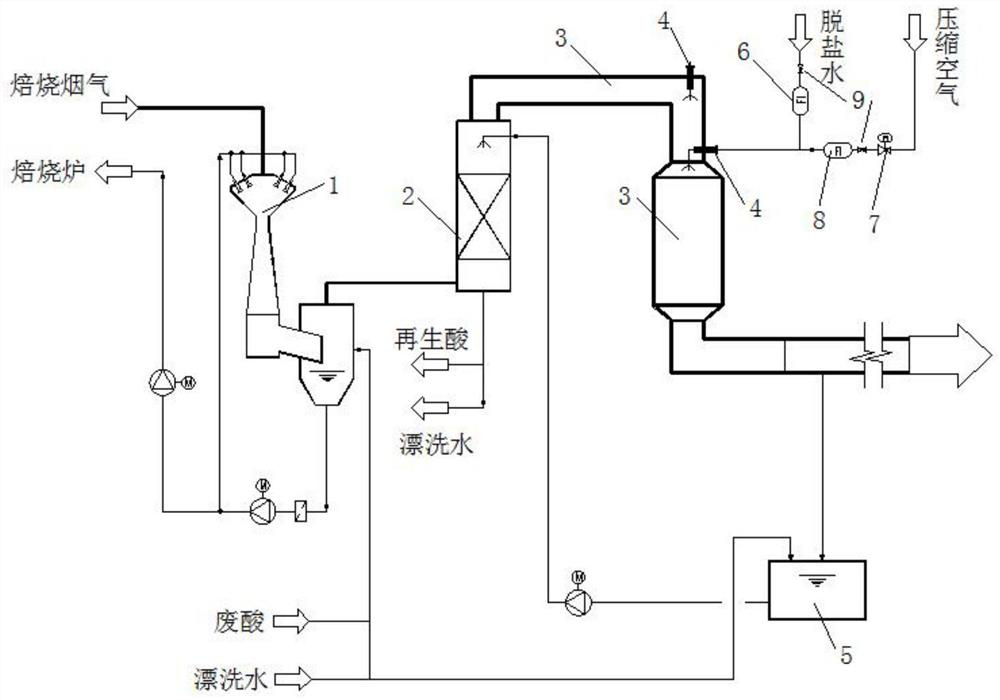

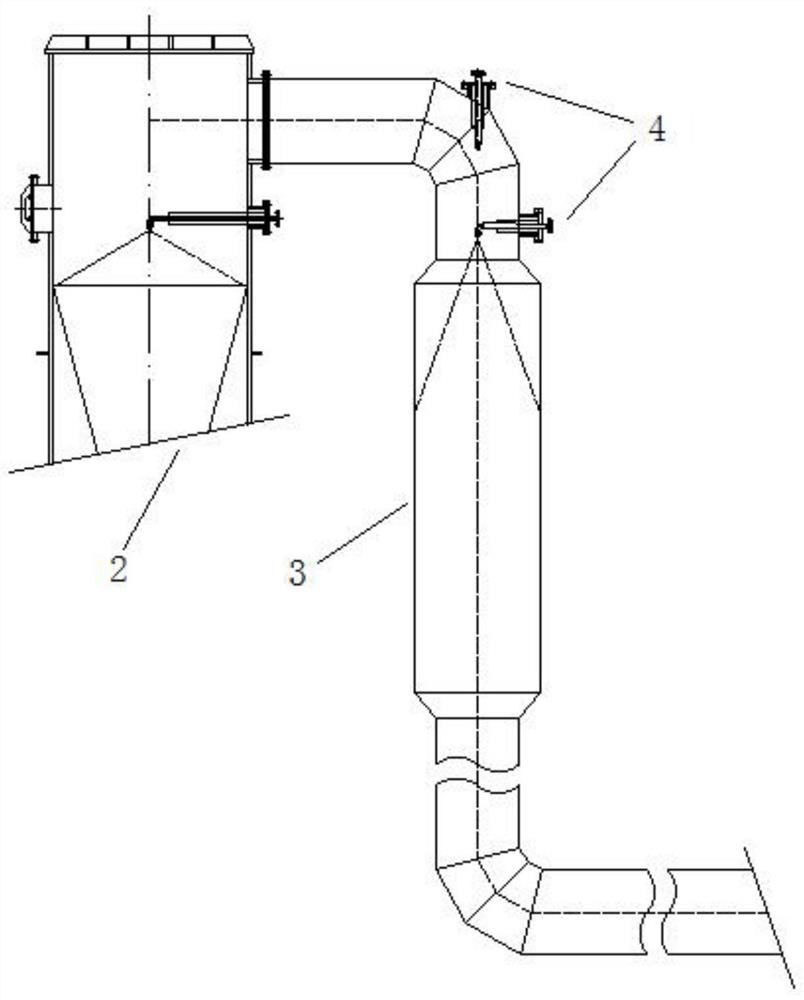

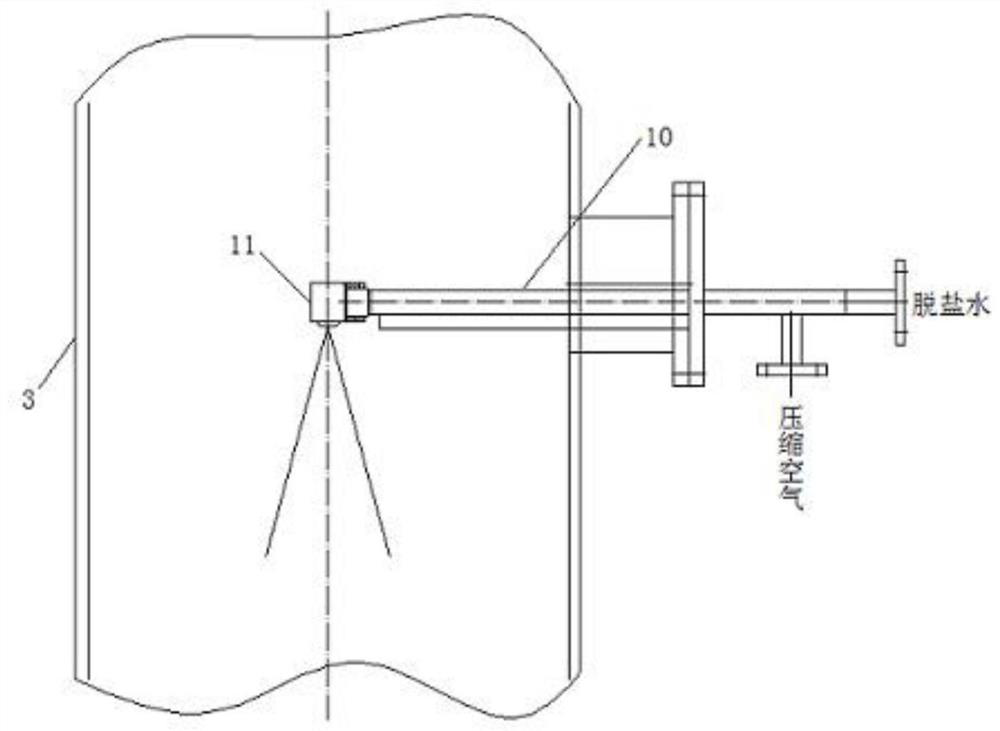

[0033] Attached to the manual figure 1 As shown, the present invention provides a device for removing particulate matter from hydrochloric acid regeneration roasting flue gas, including a Venturi pre-concentrator 1 and an absorption tower 2 that are sequentially arranged along the flow direction of the roasting flue gas, and the gas output of the absorption tower 2 is The end is connected with a flue gas pipe 3, and the roasting flue gas enters the next process through the flue gas pipe 3, and the flue gas processed by the flue gas pipe 3 can enter the packed tower, the Venturi tower and other towers according to the process requirements, or After the absorption tower, the exhaust gas fan is directly connected through the flue gas pipeline 3, and the flue gas is directly discharged after the inspection reaches the standard. There is a condenser 4 for spraying in the pipe 3, and a collection tank 5 is connected to the bottom of the flue gas pipe 3.

[0034] To refine the imple...

Embodiment 2

[0047] The present invention also provides a method for removing particulate matter from hydrochloric acid regeneration roasting flue gas. The device in Example 1 is used. After that, it enters the flue gas pipe 3 from the gas output end of the absorption tower 2, supplies desalinated water and compressed gas to the dust removal device on the flue gas pipe 3, and forms a spray in the condenser 4 so as to spray the flue gas pipe. The roasting flue gas in 3 is further dedusted and purified, and the liquid at the bottom of the flue gas duct 3 is collected by the collection tank 5 connected with the flue gas duct 3 .

[0048] To refine the implementation, the flue gas pipeline 3 can be installed at different positions according to the requirements. The dust removal device is at least one set, which can be set according to the flue gas treatment requirements. The liquid pipeline and the compressed air pipeline are provided with A control valve and a flow meter can control the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com