Man-machine interaction system of industrial robot

An industrial robot and human-computer interaction technology, applied in the field of human-computer interaction systems, can solve the problems of slow progress of the process and lack of interactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

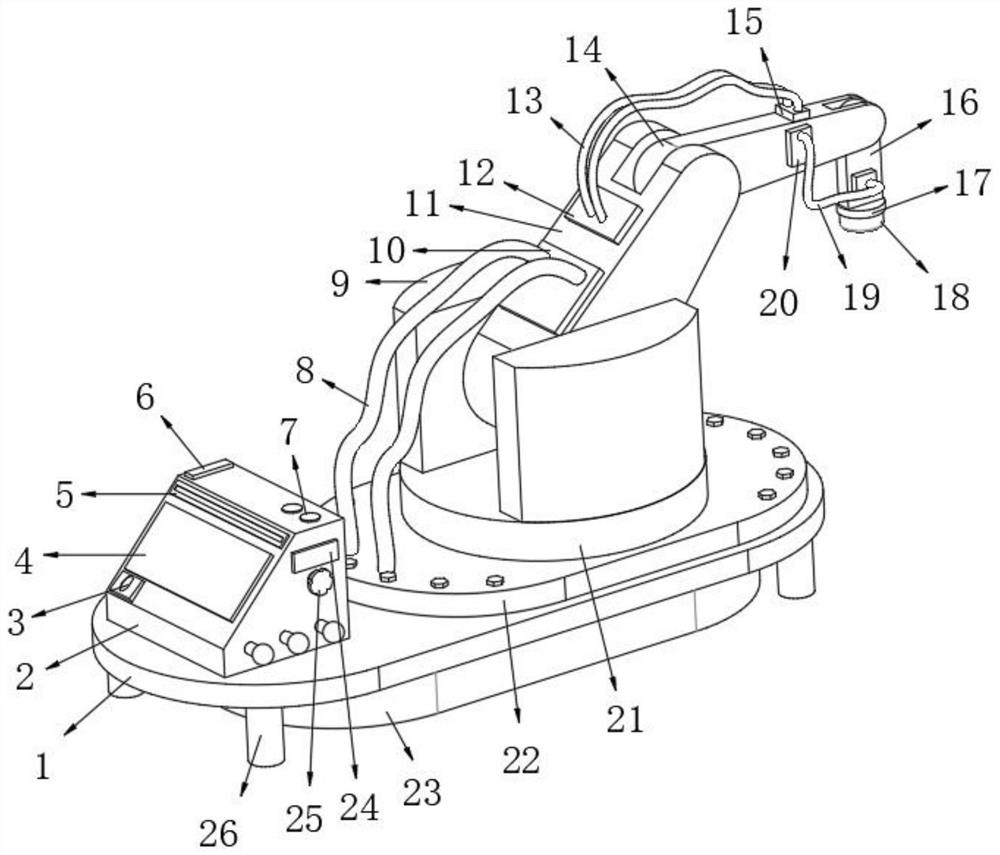

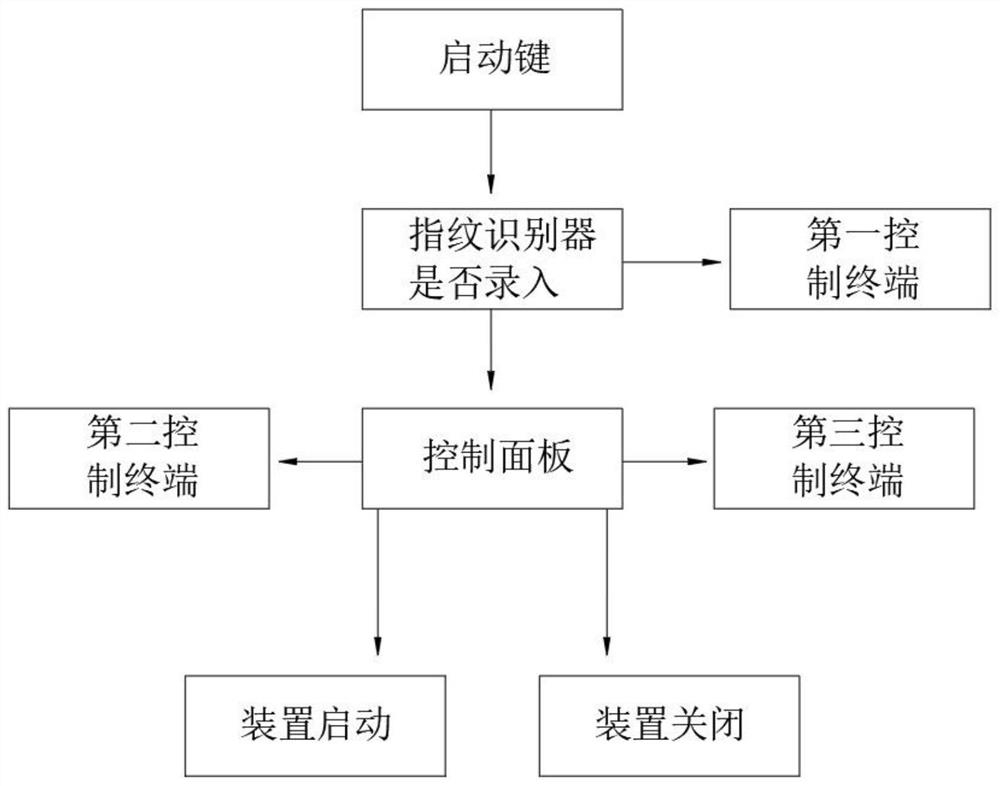

[0030] refer to Figure 1-6 , a human-computer interaction system for an industrial robot, comprising a base 1, a console 2, a turntable 9, a mounting plate 22 and a battery box 23, the console 2 is connected to one end of the top outer wall of the base 1 by bolts, and the mounting plate 22 passes through The bolt is connected to the other end of the top outer wall of the base 1, the battery box 23 is connected to the bottom outer wall of the base 1 by bolts, the top outer wall of the mounting plate 22 is connected to the rotating plate 21 through the bearing rotation, and the outer walls on both sides of the top of the rotating plate 21 are rotary tables. 9. A first rotating arm 11 is rotatably connected between the outer walls of the opposite side of the rotary table 9 through a bearing, and the outer wall of the other end of the first rotating arm 11 is rotatably connected with a second rotating arm 14 through a bearing. The outer wall of the other end is rotatably connecte...

Embodiment 2

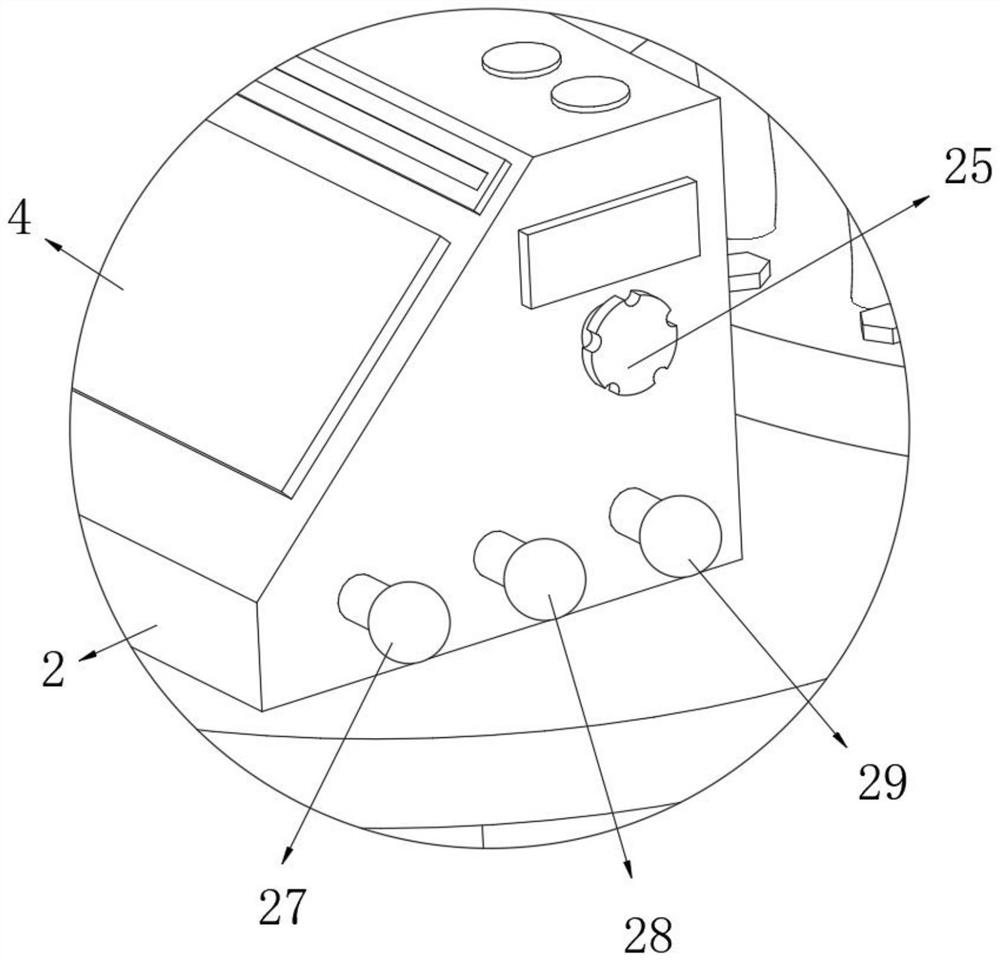

[0039] refer to Figure 7 , a human-computer interaction system for an industrial robot, the control mechanism includes a first control rod 27, a second control rod 28 and a third control rod 29, and the first control rod 27, the second control rod 28 and the third control rod 29 One side of the outer wall is made of high-strength polypropylene material.

[0040] Working principle: when the first control rod 27, the second control rod 28 and the third control rod 29 are all set to high-strength polypropylene material, when the staff operates the equipment, because the polypropylene material has chemical resistance and heat resistance It has the advantages of mechanical properties, electrical insulation, high-strength mechanical properties and good high wear-resistant processing properties, so it can provide higher protection for workers.

Embodiment 3

[0042] refer to Figure 8 , a human-computer interaction system for an industrial robot, the control mechanism includes a first control rod 27, a second control rod 28 and a third control rod 29, and the first control rod 27, the second control rod 28 and the third control rod 29 The outer walls of one side are all set with three different colors of rubber material, and the outer walls of one side of the first rotating arm 11, the second rotating arm 14 and the third rotating arm 16 are respectively pasted with the first control rod 27, the second control rod 28 and the third lever 29 corresponding to the display board

[0043] Working principle: when the first control rod 27, the second control rod 28 and the third control rod 29 are all set to be made of rubber, it not only enhances the protection effect of the staff, but also prevents the leakage of the device from endangering the safety of the staff. With different color markings can reduce operator errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com