Supercritical foaming EVA (Ethylene Vinyl Acetate) sole forming equipment and method

A molding equipment and supercritical technology, used in footwear, bulk chemical production, household appliances, etc., can solve the problems of reduced production efficiency, burns of staff, and high temperature of shoe soles, so as to improve production efficiency and ensure no burns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

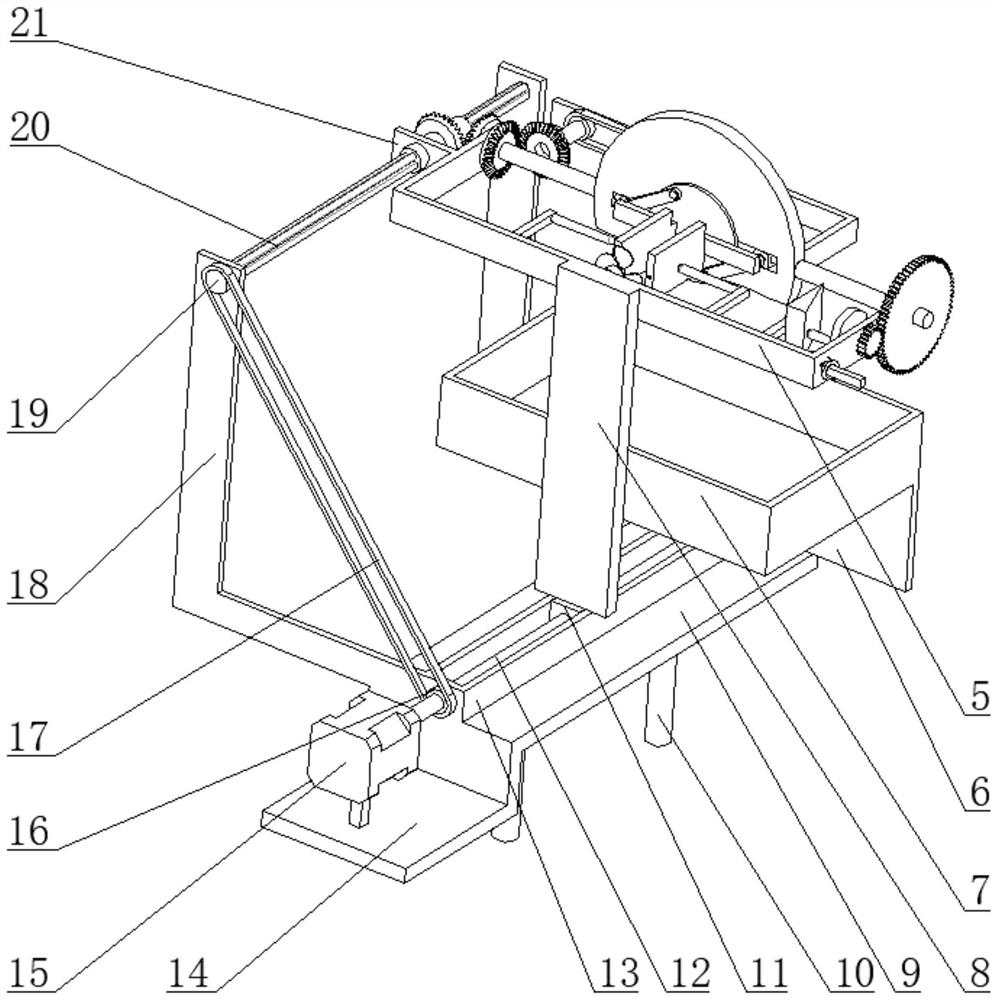

[0037] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

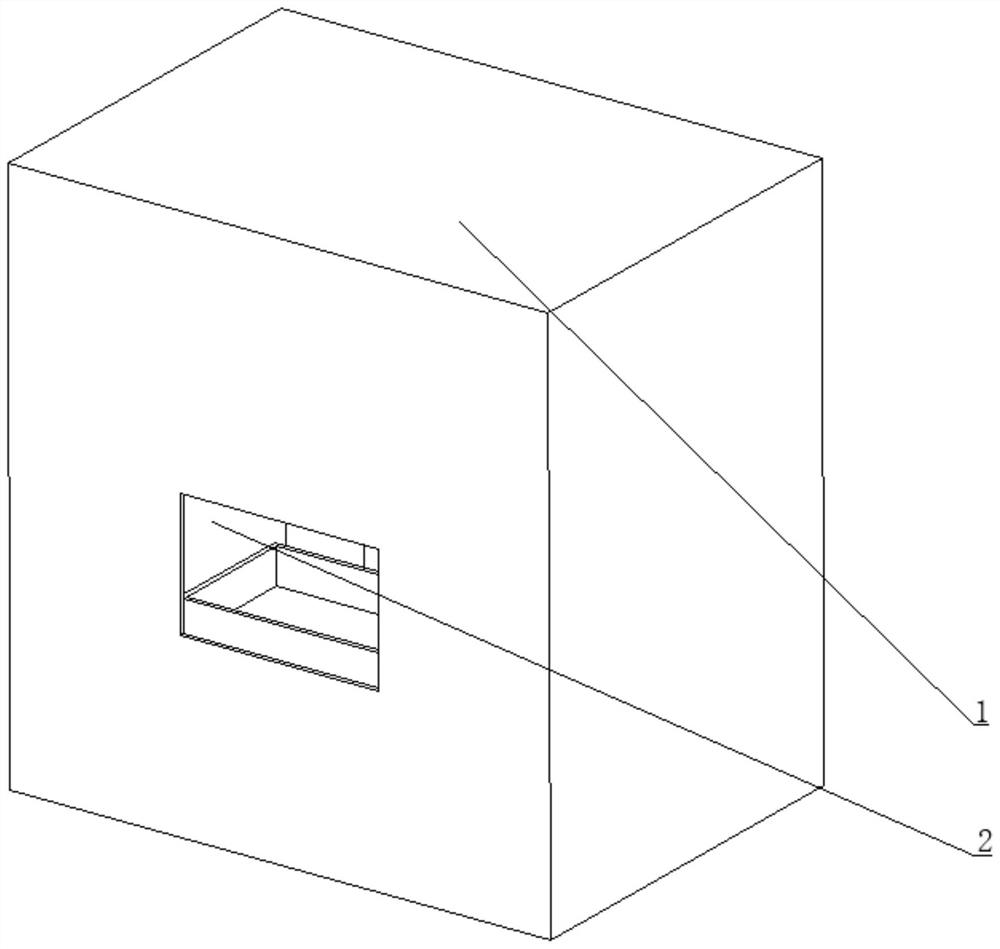

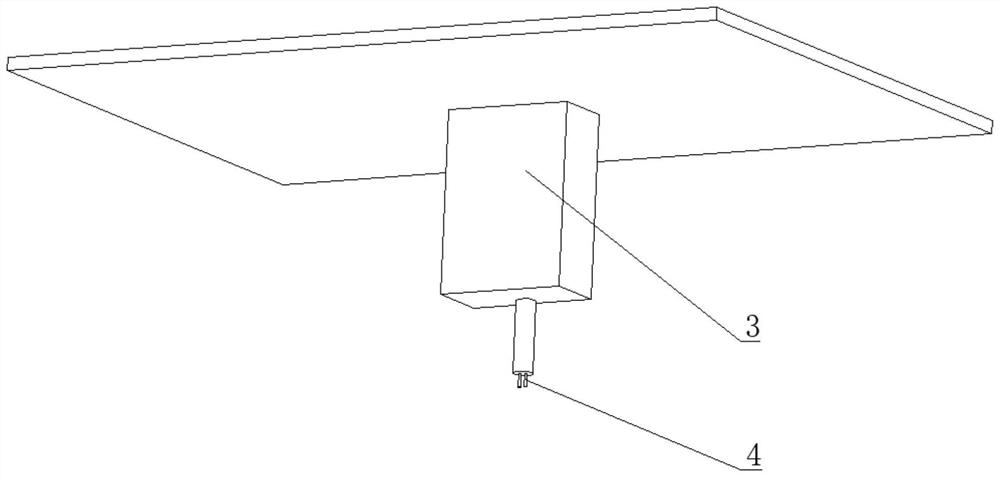

[0038] like Figure 1-Figure 9 As shown, the present invention includes an equipment casing 1, which is provided with a window 2, and the equipment casing 1 is fixedly connected to a symmetrical round rod-10, and the symmetrical round rod-10 is fixedly connected to the square plate 9, respectively, so The square plate 9 is fixedly connected to the vertical plate 1 6 , the square plate 9 is fixedly connected to the chute 13 , the square plate 9 is fixedly connected to the L plate 1 14 , the vertical plate 1 6 is fixedly connected to the box body 7 , and the chute 13 The symmetrical L-shaped rod one 18 is fixedly connected, the equipment housing 1 is fixedly connected to the injection molding machine 3, the injection molding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com