Sludge reduction and drying treatment device and use method thereof

A treatment device and sludge technology, which is applied in dewatering/drying/concentrating sludge treatment, energy and wastewater treatment, etc., can solve problems such as the existence of moisture, affecting sludge time, affecting sludge drying efficiency, etc., to improve efficiency, stabilize and stabilize sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

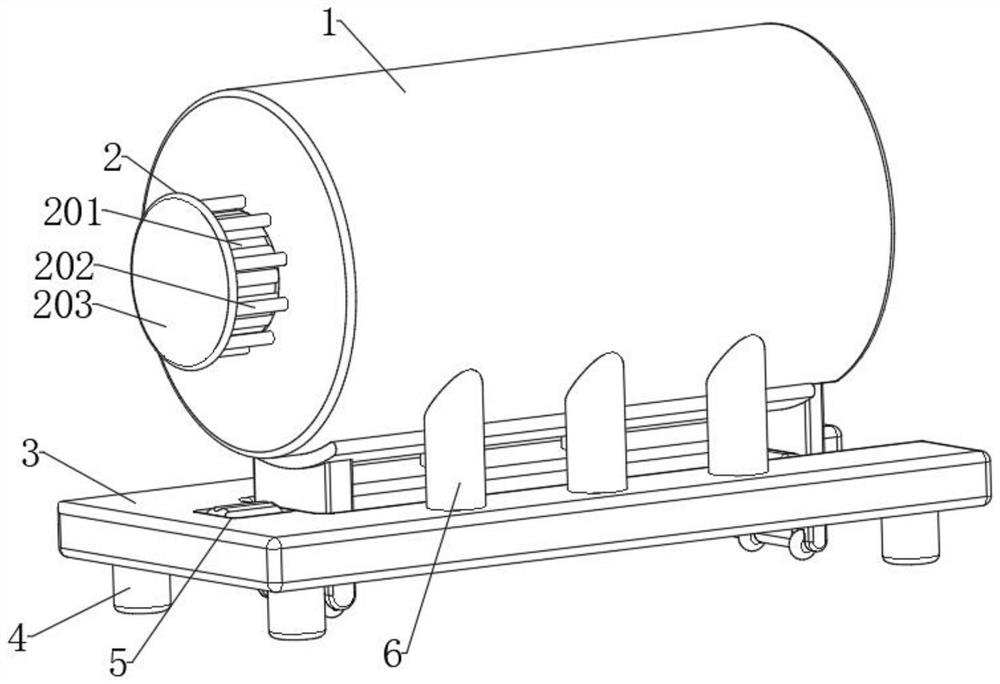

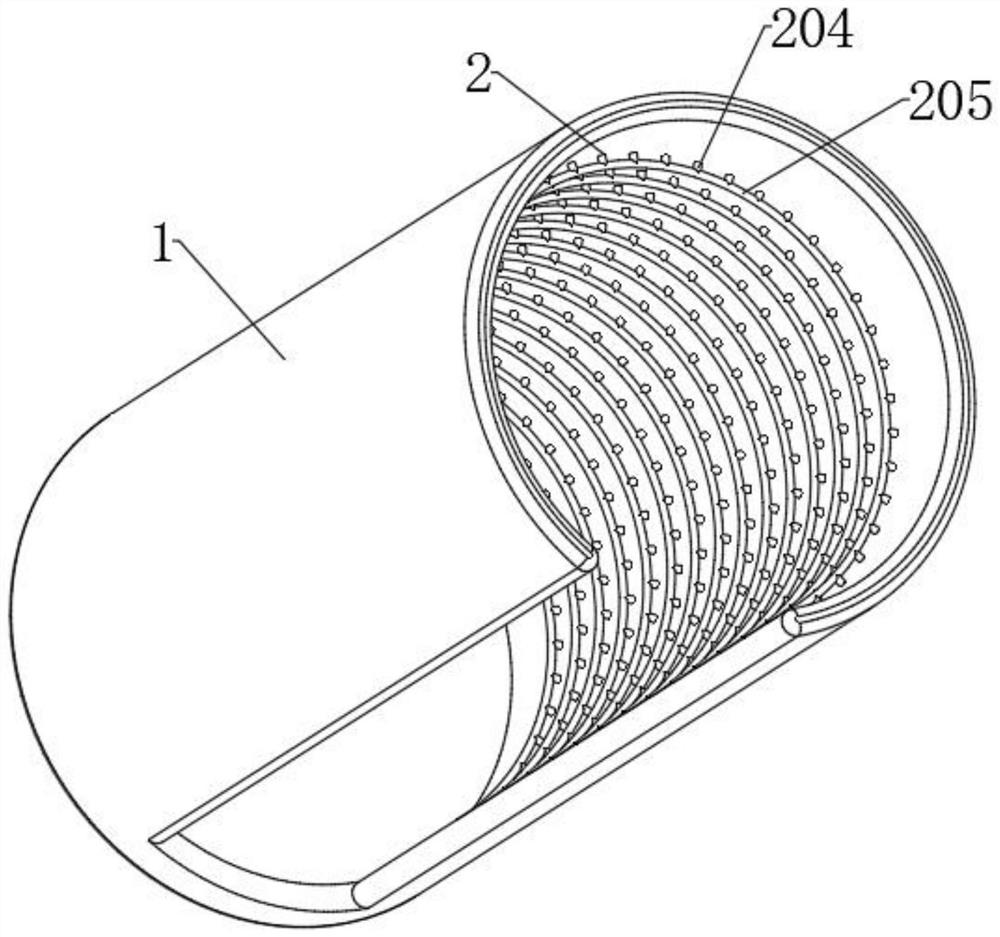

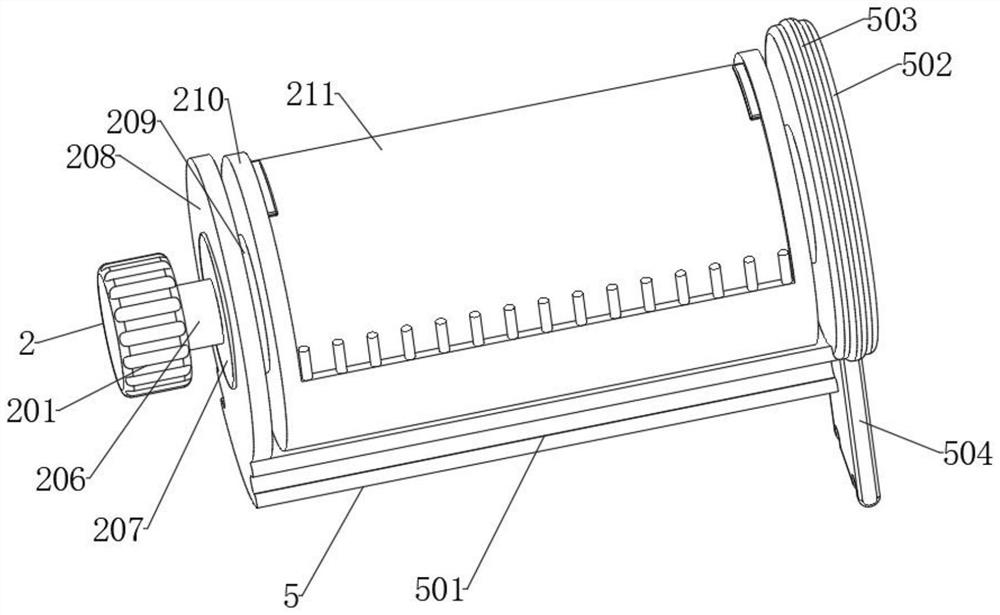

[0041] like figure 1 , figure 2 , image 3 , Figure 4 and Image 6 As shown, the present invention provides a technical solution: a sludge reduction and drying treatment device, comprising a casing 1, an evaporation mechanism 2 is arranged inside the casing 1, a bottom plate 3 is arranged at the bottom of the casing 1, and the bottom of the bottom plate 3 is fixedly connected There are support legs 4, the bottom of the casing 1 is provided with a moving mechanism 5, the top of the bottom plate 3 is fixedly connected with a support rod 6, the interior of the casing 1 is provided with a fixing mechanism 7, and the evaporation mechanism 2 includes a first motor 201. The first motor 201 is provided with On one side of the casing 1, a first motor 201 is provided so that the device can normally perform evaporation and drying treatment on the sludge. A guardrail 202 is sleeved on the outer surface of the first motor 201, and one end of the guardrail 202 is fixedly connected with...

Embodiment 2

[0048] This embodiment is further described for Example 1, such as figure 1 , image 3 , Figure 7 As shown, the moving mechanism 5 includes a sliding plate 501, the top of the sliding plate 501 is fixedly connected to the bottom of the first side plate 208, the top of the sliding plate 501 is fixedly connected with a second side plate 502, and the outer surface of the second side plate 502 is adhered with a seal Ring 503, by setting the sealing ring 503, the inside of the casing 1 after the heating wire 205 runs has a good sealing feature, which improves the efficiency of evaporating and drying the sludge. The bottom of the second side plate 502 is fixedly connected with a first vertical plate 504, A second motor 505 is fixedly installed inside the bottom plate 3. By setting the second motor 505, the placing plate 210 can be moved by the operation of the second motor 505 when it is moved out from the inside of the housing 1. The bottom of the slide plate 501 is fixedly conne...

Embodiment 3

[0051] This embodiment is further described for Example 1, such as Figure 4 and Figure 5 As shown, the fixing mechanism 7 includes a fixing rod 701, and the bottom end of the fixing rod 701 is fixedly connected to the bottom end of the placing plate 210. By arranging the fixing rod 701 on the placing plate 210, the top cover 211 is limited by the fixing rod 701 One side of the placing plate 210 slides through the fixing plate 702, one side of the fixing plate 702 moves through the limiting plate 703, and the inside of the placing plate 210 is fixedly connected with a second limiting rod 704. By adding a second limiting rod 704, so that the limit plate 703 has a good limit feature when moving, the outer surface of the second limit rod 704 is sleeved with a spring 705, and by setting the spring 705, the fixing plate 702 can be released by the spring 705. Affected by the external force, the force when the shape is restored will restore the position, the outer surface of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com