High-sintering-activity pure-phase nano MgAl2O4 powder as well as preparation method and application thereof

A technology of sintering activity and mgal2o4 is applied in the field of ceramic powder preparation, which can solve the problems of adverse effects of later application of powder and increase the impurity content of powder, and achieves the effect of simple and easy process, improved sintering activity and short diffusion distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A pure phase nano-MgAl with high sintering activity 2 O 4 The preparation method of powder comprises the following process steps:

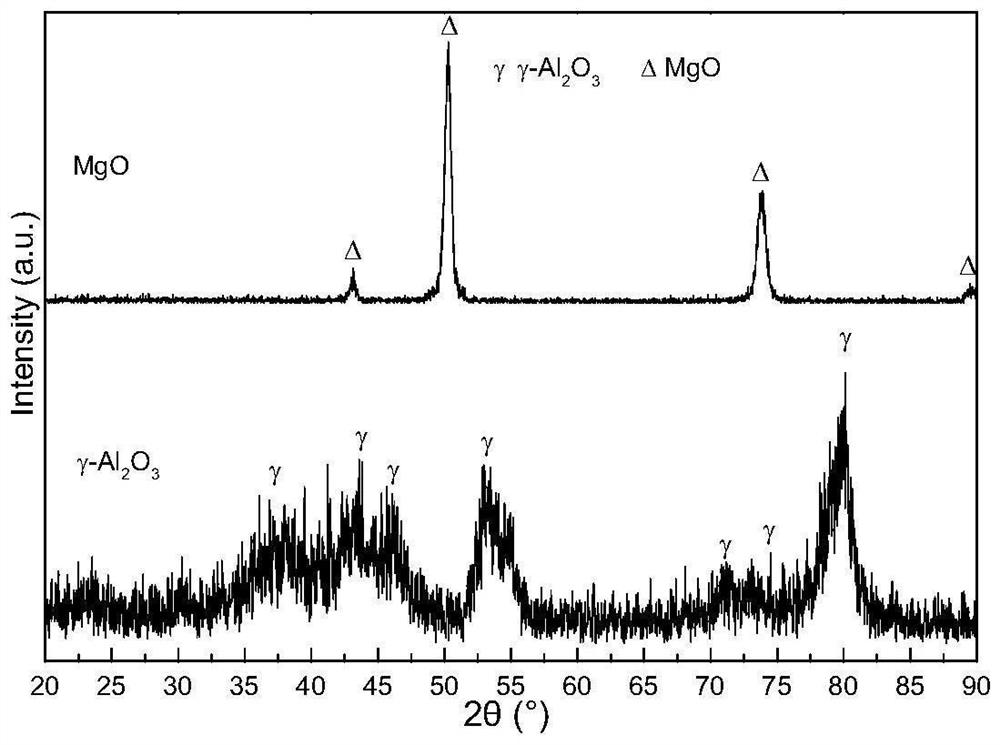

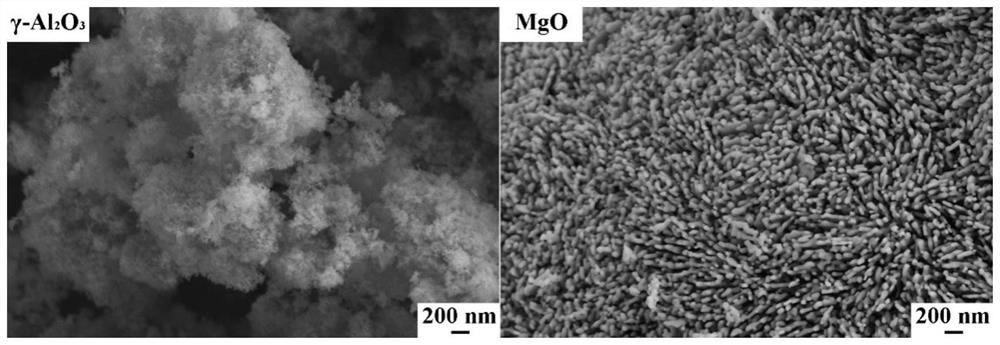

[0042] (1) Weigh γ-Al in a molar ratio of 1:1 to 1.3:1 2 O 3 and MgO raw material powder, wherein the raw material γ-Al 2 O 3 and MgO are high-purity nano-powders, among which γ-Al 2 O 3 Purity ≥99.9%, average particle size ≤40nm, specific surface area ≥120m 2 / g; MgO consists of Mg(OH) 2 Obtained by calcining at 600℃ for 60min in air, the purity is ≥99.9%, the average primary particle size is ≤90nm, and the specific surface area is ≥15m 2 / g;

[0043] (2) Using absolute ethanol as a medium, the weighed γ-Al 2 O 3 Mixed with MgO powder in a planetary ball mill at 170rpm for 20-30h;

[0044] (3) drying the slurry after ball milling and passing through a 60-80 mesh sieve;

[0045] (4) γ-Al obtained by drying and granulation 2 O 3 The powder mixed with MgO is put into a crucible and placed in a box furnace. 2 O 4 For powder, t...

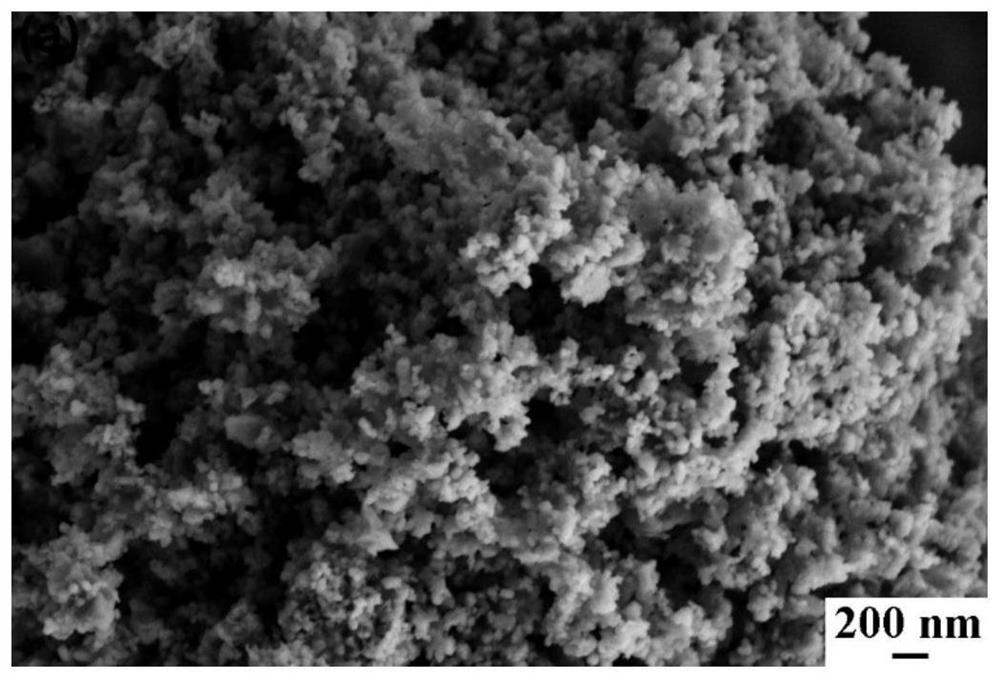

Embodiment 1

[0048] With a purity of 99.99%, an average particle size of 14nm, and a specific surface area of 128m 2 / g of γ-Al 2 O 3 Powder and calcined Mg(OH) in air at 600℃ for 60min 2 The obtained pure phase MgO powder (average particle size 80nm, specific surface area 21m 2 / g) as raw material (γ-Al 2 O 3see the phase composition of MgO figure 1 , see figure 2 ), press γ-Al 2 O 3 and MgO molar ratio 1:1 (γ-Al 2 O 3 71.83wt.%, MgO 28.17wt.%) Weigh 20g of raw material powder, add 100ml of absolute ethanol to prepare γ-Al 2 O 3 The mixed slurry with MgO was milled on a planetary ball mill at 170 rpm for 24 hours, and the obtained mixed slurry was dried, passed through a 60-mesh sieve, γ-Al 2 O 3 The morphology of +MgO mixed powder is as follows image 3 shown.

[0049] The γ-Al 2 O 3 +MgO mixed powder into Al 2 O 3 Put the crucible into a box furnace, heat it up to 1250 °C for 60 min at 10 °C / min in an air environment, turn off the power and cool with the furnace to...

Embodiment 2

[0053] The difference between Example 2 and Example 1 is that γ-Al 2 O 3 The mass ratio of MgO and MgO is 1.1:1, the obtained pure phase MgAl 2 O 4 The XRD pattern of the powder is shown in Figure 4 , see Figure 12 , the specific surface area of the obtained powder was measured to be 24.99m 2 / g, the average primary particle size is 67 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com