Vinyl acetate embossed wear-resistant and high-temperature-resistant placemat and preparation method thereof

A technology of vinyl acetate and vinyl acetate copolymer, which is applied in the direction of table utensils, artificial silk manufacturing, single-component polyamide artificial filament, etc., can solve the problems of small high temperature resistance range, insufficient wear resistance, difficult problems, etc., to achieve The material is environmentally friendly and can withstand a wide range of temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

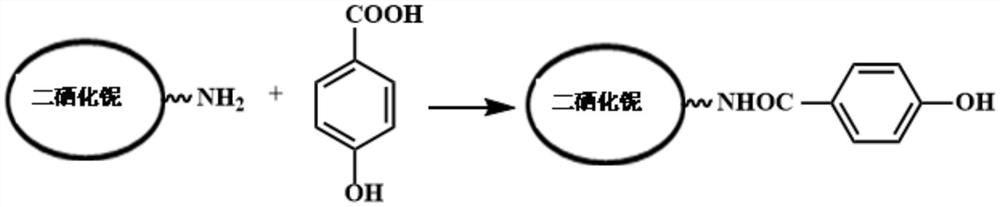

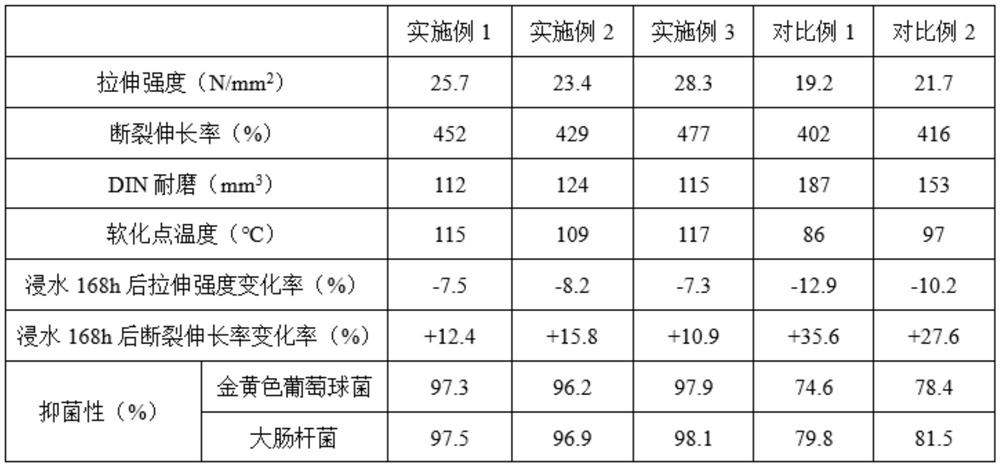

[0065] A wear-resistant, scratch-resistant, high-temperature-resistant vinyl acetate embossed placemat, calculated in parts by weight, includes the following components:

[0066] 61.4 parts of ethylene-vinyl acetate copolymer, 25.8 parts of low density polyethylene, 19.3 parts of modified polyparabenzamide fiber, 2.7 parts of EVA masterbatch, 3.8 parts of plasticizer, 0.7 parts of antioxidant, 3.2 parts of flame retardant and 0.4 parts of light stabilizer.

[0067] Among them, the model of ethylene-vinyl acetate copolymer is EVA18J3, the molecular weight is 100000-200000, the vinyl acetate content is 10%-15%; the model of low density polyethylene is LDPE-2420H, the molecular weight is 50000-60000; the plasticizer is Dioctyl phthalate; antioxidant is obtained by compounding antioxidant 1076 and antioxidant 168 in a mass ratio of 4:1; flame retardant is an organophosphorus composite flame retardant, including a mass ratio of 3: 1 of ammonium polyphosphate and melamine polyphosp...

Embodiment 2

[0098] A preparation method of a vinyl acetate embossed wear-resistant, scratch-resistant and high-temperature placemat is the same as that in Example 1.

[0099] The vinyl acetate embossed wear-resistant, scratch-resistant and high-temperature-resistant placemat, calculated in parts by weight, includes the following components:

[0100] 57.2 parts of ethylene-vinyl acetate copolymer, 28.7 parts of low density polyethylene, 15.1 parts of modified polyparabenzamide fiber, 2.1 parts of EVA masterbatch, 4.5 parts of plasticizer, 0.5 parts of antioxidant, 2.4 parts of flame retardant and 0.2 parts of light stabilizer.

[0101] Among them, the model of ethylene-vinyl acetate copolymer is EVA18J3, the molecular weight is 100000-200000, the vinyl acetate content is 10%-15%; the model of low density polyethylene is LDPE-2420H, the molecular weight is 50000-60000; the plasticizer is Dioctyl phthalate; antioxidant is obtained by compounding antioxidant 1076 and antioxidant 168 in a mas...

Embodiment 3

[0116] A preparation method of a vinyl acetate embossed wear-resistant, scratch-resistant and high-temperature placemat is the same as that in Example 1.

[0117] The vinyl acetate embossed wear-resistant, scratch-resistant and high-temperature-resistant placemat, calculated in parts by weight, includes the following components:

[0118] 66.5 parts of ethylene-vinyl acetate copolymer, 21.4 parts of low density polyethylene, 22.3 parts of modified polyparabenzamide fiber, 3.2 parts of EVA masterbatch, 3.3 parts of plasticizer, 1 part of antioxidant, 3.6 parts of flame retardant and 0.6 parts of light stabilizer.

[0119] Among them, the model of ethylene-vinyl acetate copolymer is EVA18J3, the molecular weight is 100000-200000, the vinyl acetate content is 10%-15%; the model of low density polyethylene is LDPE-2420H, the molecular weight is 50000-60000; the plasticizer is Dioctyl phthalate; antioxidant is obtained by compounding antioxidant 1076 and antioxidant 168 in a mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com