Production device of lactonase

A production device and technology of lactonase, which is applied in the field of lactonase, can solve problems such as not easy to stir evenly, time-consuming and laborious, and difficult to clean the warehouse, so as to achieve the effects of enhancing stability, ensuring sealing, and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

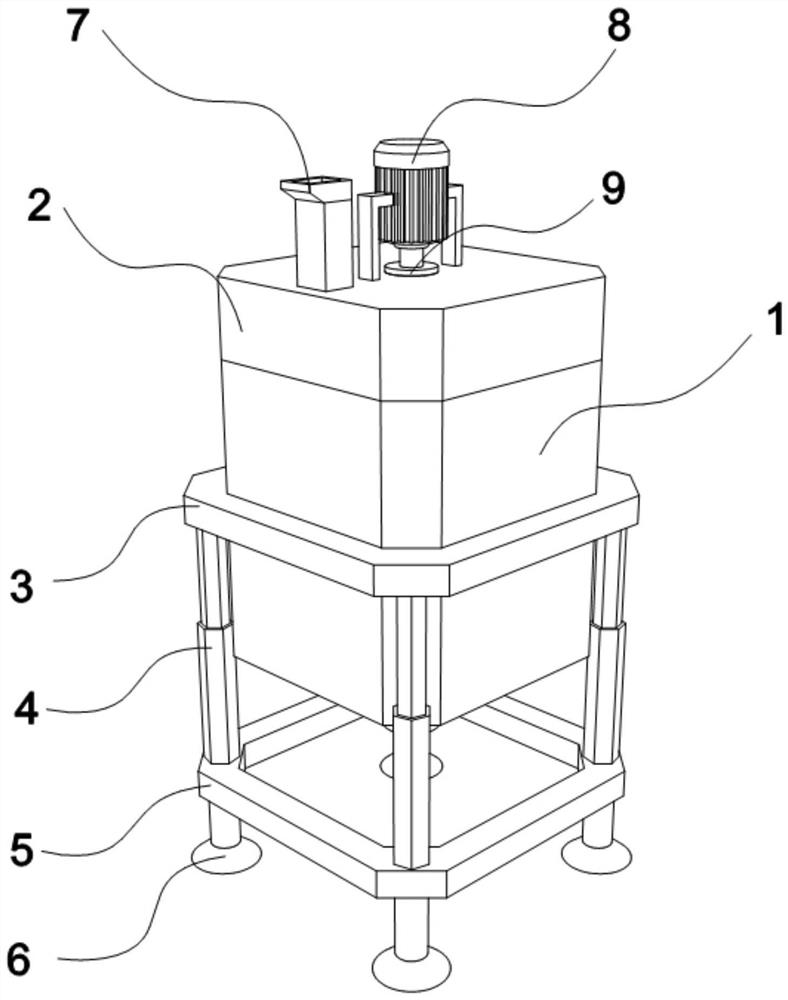

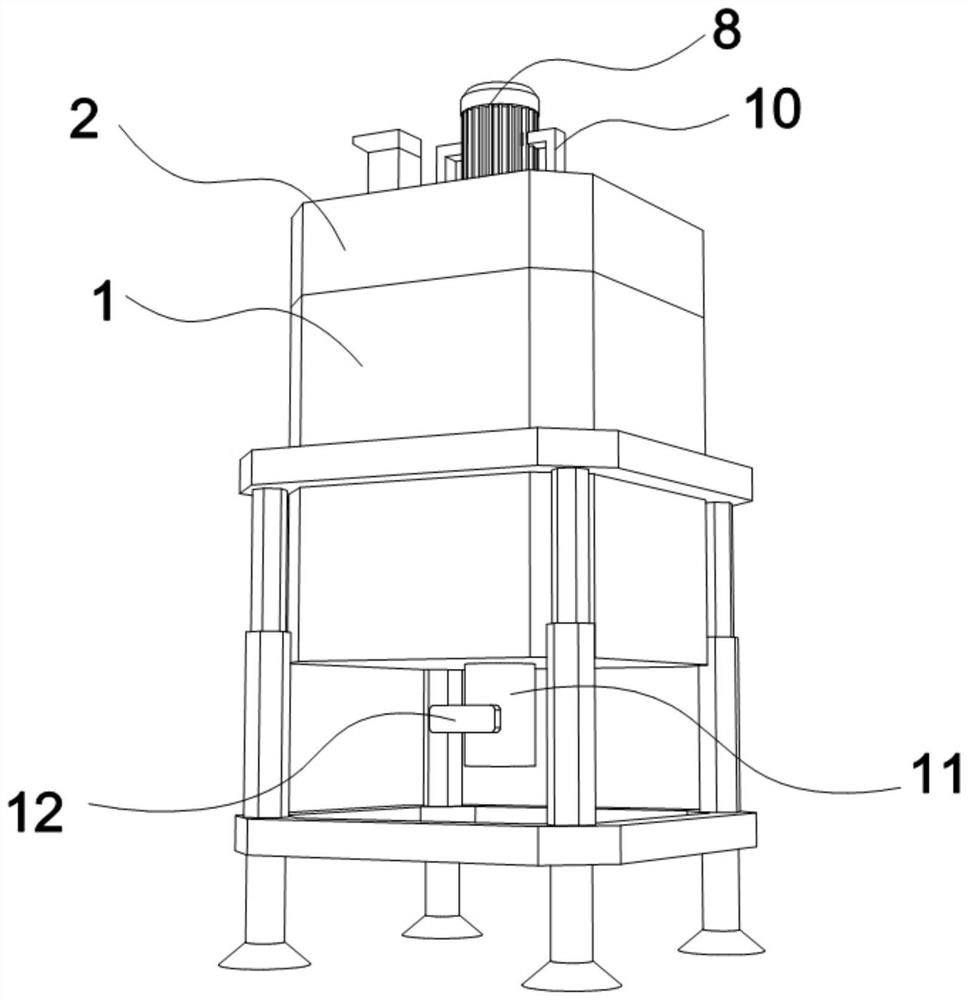

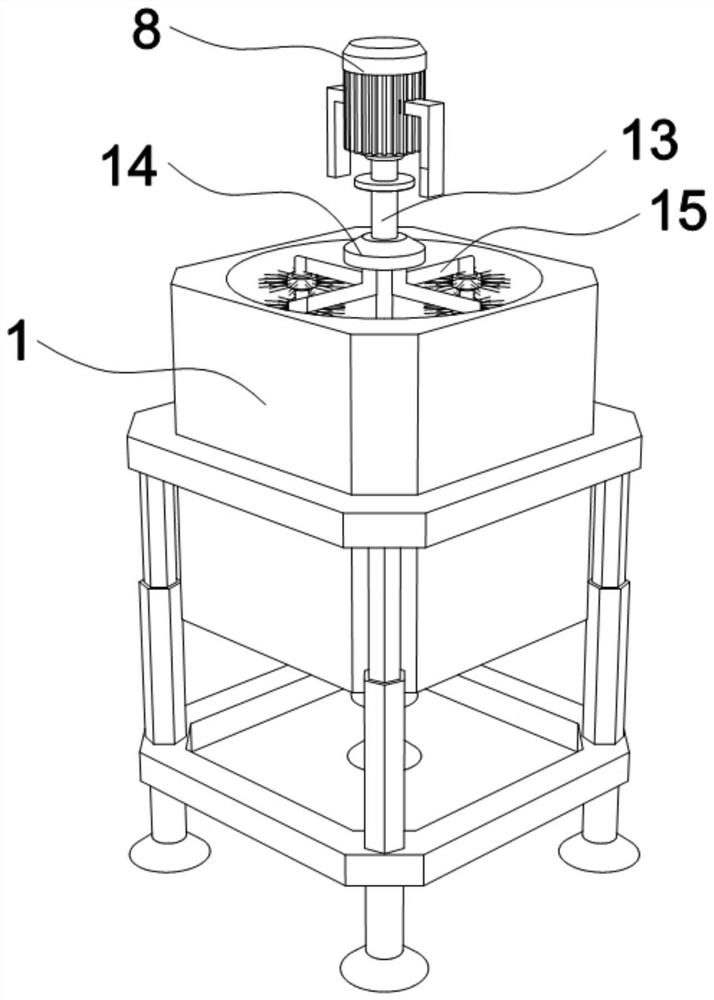

[0030] refer to Figure 1-10 , a production device of lactonase, comprising a warehouse body 1, one side of the warehouse body 1 is provided with a controller, the controller electrically controls each electrical component, the upper surface of the warehouse body 1 is provided with a top cover 2, and the top cover A motor 8 is provided at the top center position of One end is provided with a round block 14, and the bottom of the round block 14 is provided with several stirring parts 15. The stirring parts 15 can not only stir the inside of the silo body 1, but also clean it to ensure the cleaning performance inside the silo body 1. .

[0031]The stirring part 15 includes a plurality of sets of horizontal frames 1511, one side of the horizontal frame 1511 is fixedly connected with the bottom of the round block 14, the other side of the horizontal frame 1511 is provided with an electromagnet 1510, and the bottom of the electromagnet 1510 is provided with a support rod 1501. A ...

no. 2 example

[0045] Based on the production device for lactonase provided by the first embodiment, in actual use, there are often lumpy reactants adhered to the inner wall or bottom of the chamber body 1, which not only reduces the quality of the reaction, but also affects the subsequent reactions. At the same time, because most of the existing adjacent brushes have a certain gap, it is impossible to stir and clean the reactants between the brush gaps, and there is a large block adhesion at the bottom of the silo body 1. Since the height of the bottom circular plate 18 and the bottom of the silo body 1 is constant, the large brush 19 cannot break the adhering objects when cleaning them, and long-term use will also cause the large brush 19 to deform, further reducing the Cleaning effect, in order to solve the above problems, the production device of the lactonase also has the following process in actual use.

[0046] When in use, the reactant is added to the interior of the bin body 1 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com