Cobalt-chromium alloy for finger ring and preparation method of cobalt-chromium alloy

A technology of cobalt-chromium alloy and ring, applied in the field of cobalt-chromium alloy, can solve the problems of poor toughness and plasticity, poor toughness and plasticity, and high production cost of cobalt-chromium alloy, so as to improve plasticity and toughness, good plasticity and bending strength. , the effect of reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method for a ring ring cobalt-chromium alloy, comprising the following steps;

[0023] 1) Weigh the alloy components, and weigh 25.0wt.% of Cr, 0.5wt.% of Mo, 0.5wt.% of Mn, 0.2wt.% of Fe, 0.1wt.% of Ti, 0.15wt.% C, the balance being Co;

[0024] 2), carry out vacuum smelting with the alloy composition weighed in step 1), and then carry out casting at 1450 ℃ temperature to obtain casting embryo;

[0025] 3), heat treatment, the obtained billet is kept at 1200°C for 1 hour, quenched to room temperature with water, then kept at 700°C for 2 hours, and quenched with water to room temperature to obtain a cobalt-chromium alloy for a ring of the present invention;

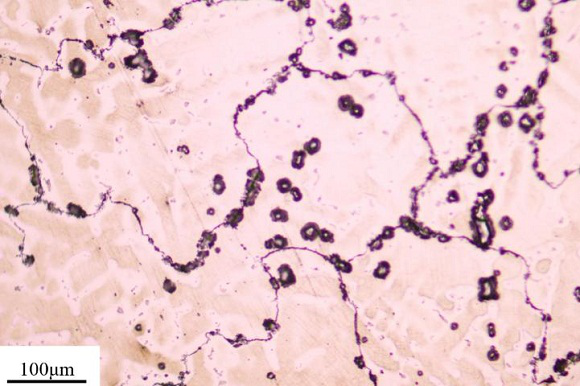

[0026] 4), the cobalt-chromium alloy is obtained through the above steps, the range of each phase structure is: FCC phase 45%±2%, HCP phase 55%±2%; the range of flexural strength is: 1950MPa±20MPa; microstructure see figure 1 shown.

Embodiment 2

[0028] A preparation method for a ring ring cobalt-chromium alloy, comprising the following steps;

[0029] 1) Weigh the alloy components, and weigh 25.0wt.% of Cr, 0.5wt.% of Mo, 0.5wt.% of Mn, 0.2wt.% of Fe, 0.1wt.% of Ti, 0.15wt.% C, the balance being Co;

[0030] 2), carry out vacuum smelting with the alloy composition weighed in step 1), and then carry out casting at 1600 ℃ temperature to obtain casting embryo;

[0031] 3), heat treatment, the obtained casting billet is kept at 1400 ° C for 1 hour, quenched to room temperature with water, then kept at 900 ° C for 2 hours, and quenched with water to room temperature to obtain a cobalt-chromium alloy for a ring of the present invention;

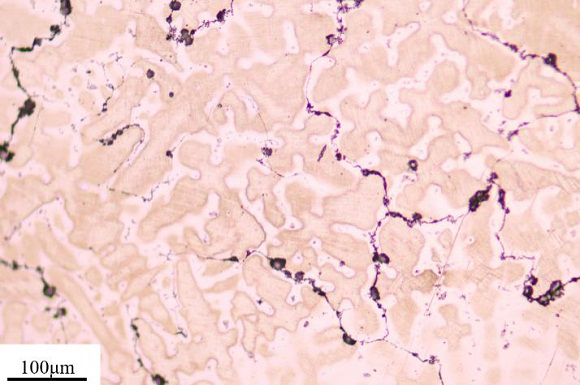

[0032] 4), the cobalt-chromium alloy is obtained through the above steps, the range of each phase structure is: FCC phase 50%±2%, HCP phase 50%±2%; the range of flexural strength is: 1900MPa±20MPa; microstructure see figure 2 shown.

Embodiment 3

[0034] A preparation method for a ring ring cobalt-chromium alloy, comprising the following steps;

[0035] 1) Weigh the alloy components, and weigh 30.0wt.% of Cr, 5.0wt.% of Mo, 1.5wt.% of Mn, 1.0wt.% of Fe, 0.6wt.% of Ti, 0.35wt.% C, the balance being Co;

[0036] 2), carry out vacuum smelting with the alloy composition weighed in step 1), and then carry out casting at 1500 ℃ temperature to obtain casting embryo;

[0037] 3), heat treatment, the obtained billet is kept at 1200°C for 1 hour, quenched to room temperature with water, then kept at 700°C for 2 hours, and quenched with water to room temperature to obtain a cobalt-chromium alloy for a ring of the present invention;

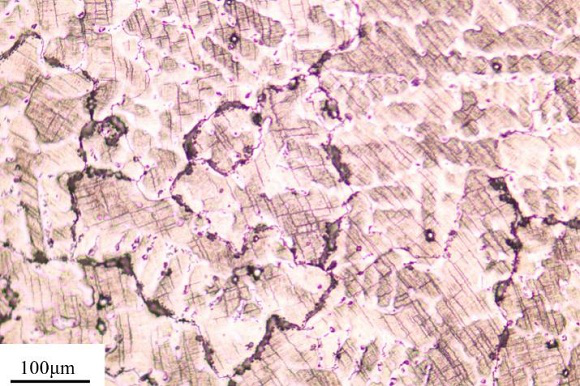

[0038] 4), the cobalt-chromium alloy is obtained through the above steps, the range of each phase structure is: FCC phase 51%±2%, HCP phase 49%±2%; the range of flexural strength is: 2400MPa±40MPa; microstructure see image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com