Pulping device for carton board body paper processing

A technology for paper processing and carton boards, applied in pulping of cellulose raw materials, pulp beating/refining methods, papermaking, etc., can solve problems such as unstable pulping quality, incomplete crushing of raw materials, and reduced pulping efficiency. The structure design is compact, the effect of improving the pulping efficiency and accelerating the dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

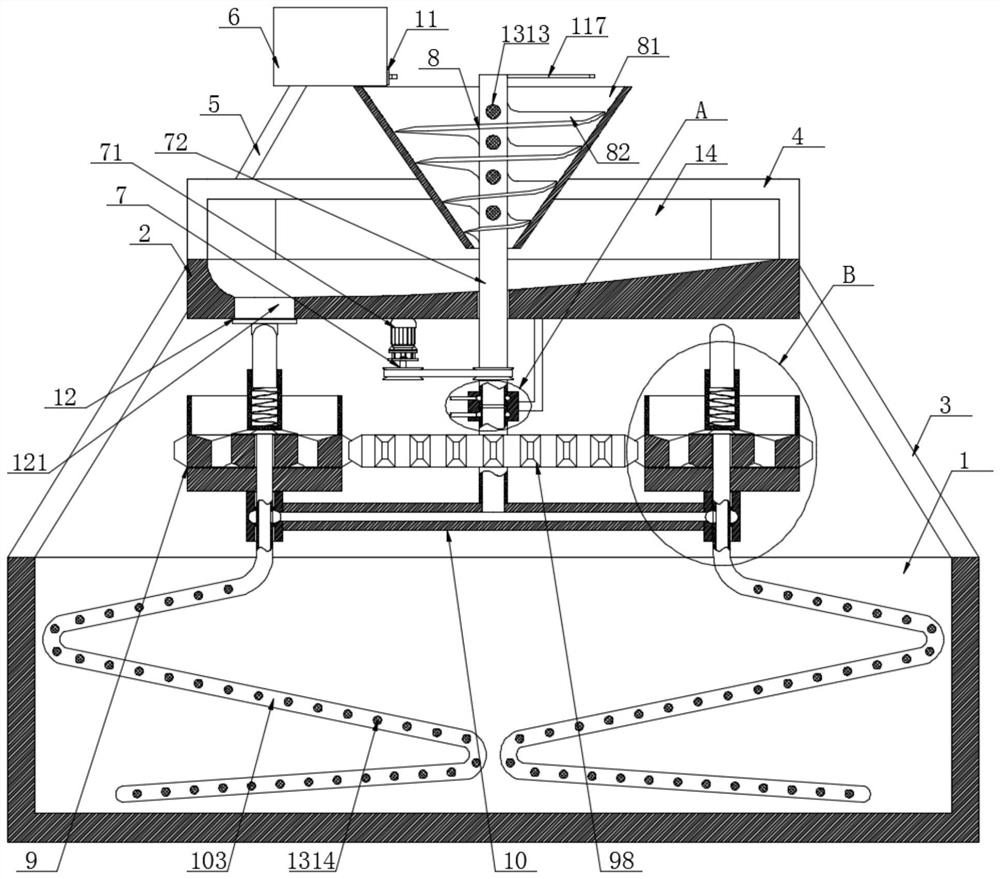

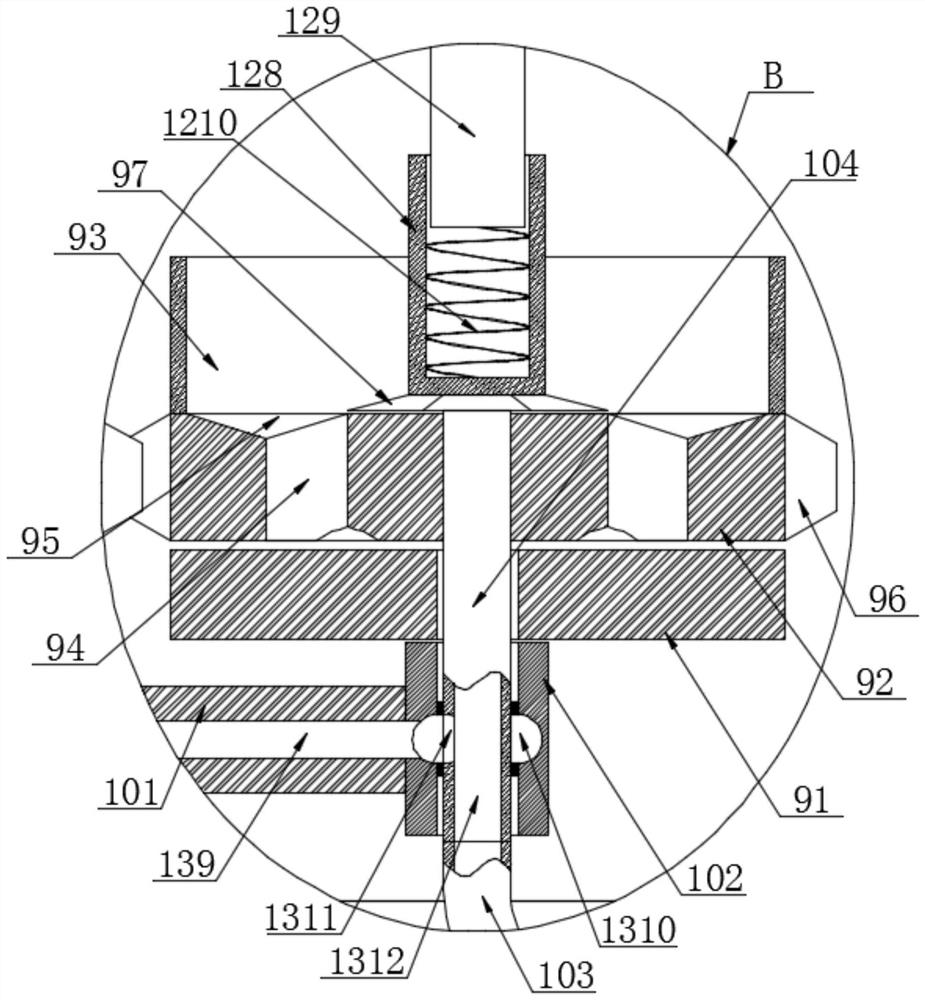

[0040] The present invention provides such as figure 1 and Figure 3-6 The shown pulping device for carton board base paper processing includes a pulp pool 1, a transition barrel 2 is provided on the top of the pulp pool 1, and a frame 3 is provided between the pulp pool 1 and the transition barrel 2, And the two are fixedly connected through the rack 3, the top of the transition barrel 2 is fixed with a bracket 4, the top of the bracket 4 is fixed with a support frame 5, and the top of the support frame 5 is fixed with a material box 6, so The bottom of the transition barrel 2 is provided with a driving mechanism 7 and the top is provided with a primary refining mechanism 8, the bottom of the transition barrel 2 is also provided with a secondary refining mechanism 9, and the slurry pool 1 is provided with a slurry dispersion mechanism. 10. The bottom end of one side of the material box 6 close to the primary refining mechanism 8 is provided with a primary discharging assembl...

Embodiment 2

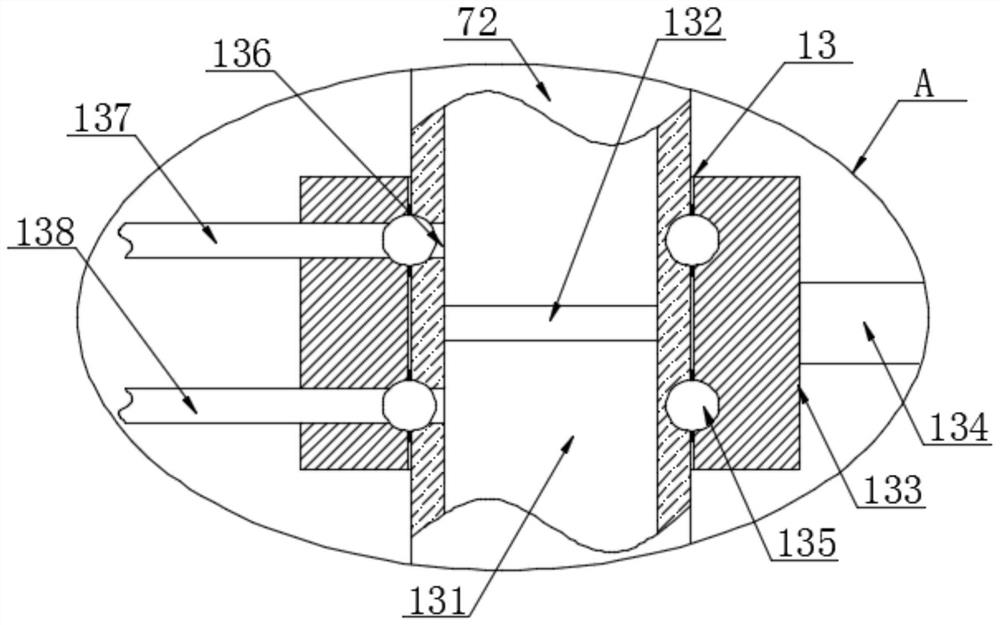

[0051] Based on the above-mentioned first embodiment, the present invention also provides such as Figure 1-6 The illustrated pulping device for carton board base paper processing, the part of the outer peripheral surface of the shaft 72 located below the motor 71 is provided with an airflow conveying assembly 13, and the airflow conveying assembly 13 includes a bottom end face of the shaft 72. The column groove 131, the column groove 131 extends to the top of the shaft 72 and does not penetrate the top surface of the shaft 72, the interior of the column groove 131 is located at the midpoint of the line between the driven wheel and the gear 98. Plate 132, a collar 133 is movably sleeved at the position of the outer peripheral surface of the shaft 72 corresponding to the partition plate 132, and an L-shaped connecting rod 134 is arranged on one side of the outer peripheral surface of the collar 133. The collar 133 is connected to the transition The bottom end surfaces of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com