Reinforcing construction method and device for large-section high-web end formwork of suspension grouting beam

A technology of end formwork and construction method, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, bridges, etc., which can solve the problem of burning the main steel bars and inner and outer formwork, and inconvenient installation and disassembly , high-altitude welding risks and other problems, to achieve the effect of protecting the construction quality, good support effect, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and embodiments.

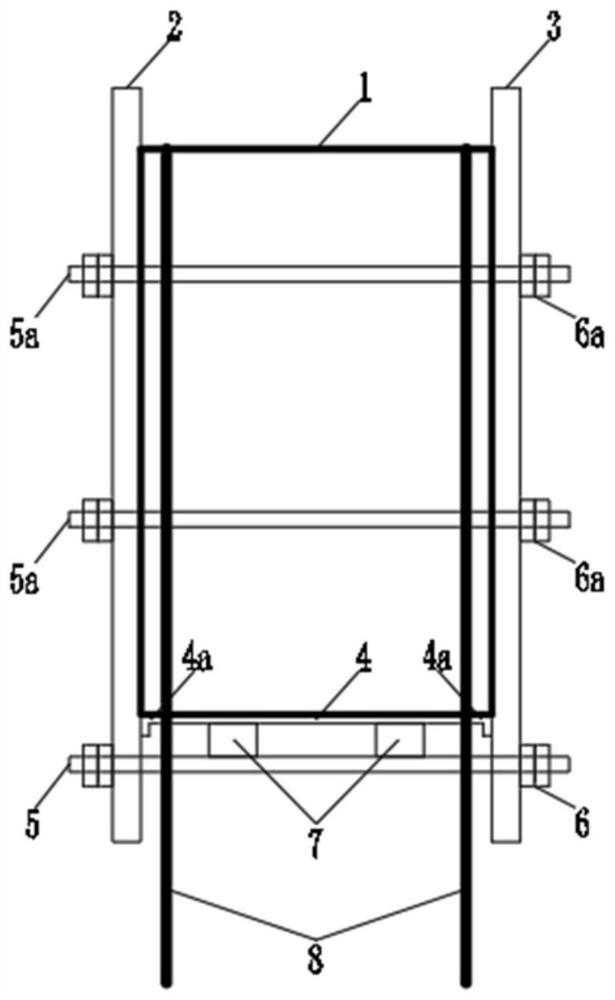

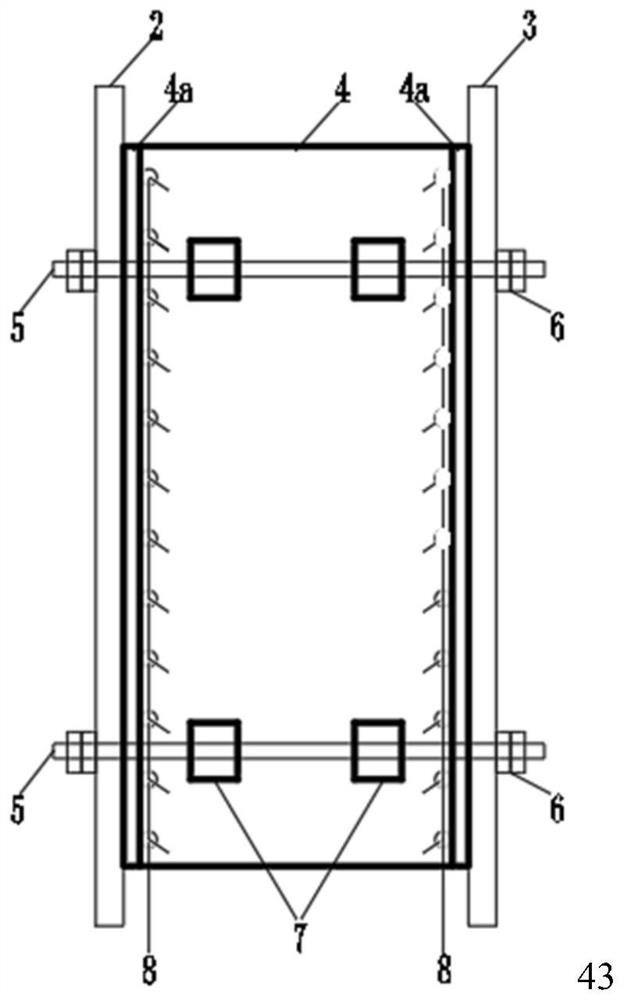

[0031] The invention provides a construction method for reinforcing the formwork of the large-section high-web end formwork of the cantilevered beam, refer to Figure 1 to Figure 5 , including the following steps:

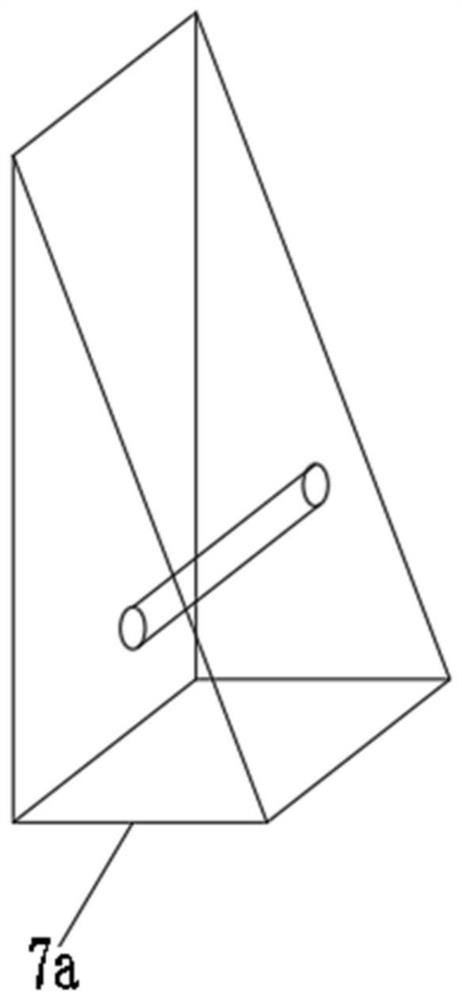

[0032] S1. End formwork processing: Pre-fabricate end formwork: Weld the end plate slot angle steel 4a on both sides of the end plate 4 to form the end formwork. The end plate is made of 5mm thick steel plate, and the end plate slot angle steel is made of The angle steel is ∠50, and the holes corresponding to the 8 positions of the longitudinal steel bars of the segment are opened on the end formwork;

[0033] S2. Construction of segmental reinforcement and formwork: Install segmental longitudinal reinforcement according to the design requirements, install outer formwork 2 and inner formwork 3 on both sides of the end formwork in parallel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com