Automatic processing device for surface defects of wall type guardrail of expressway

A technology for highways, automatic handling, applied to road safety devices, roads, roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

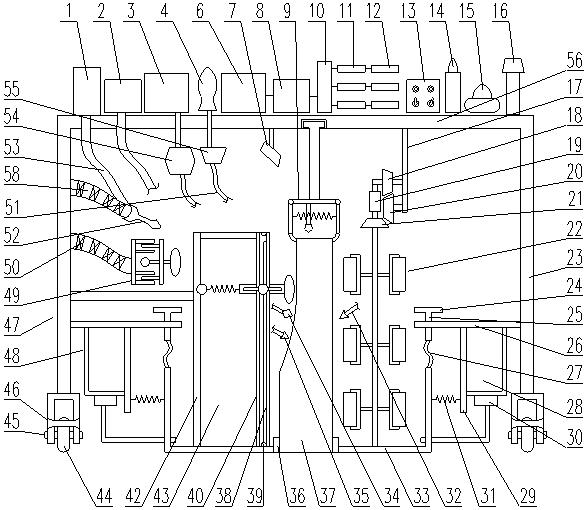

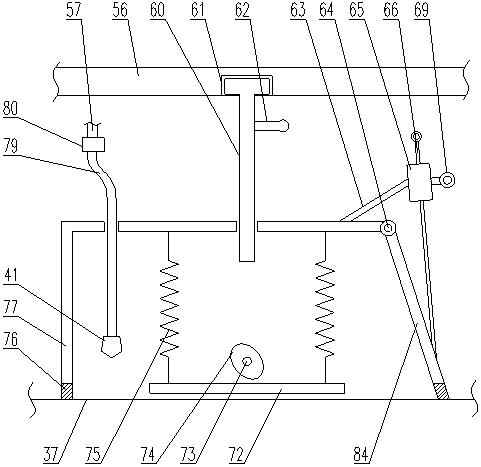

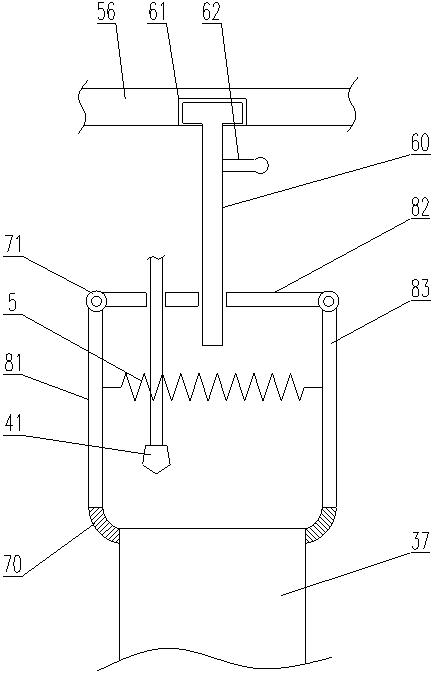

[0030] like Figure 1-10 As shown, the automatic processing device for surface defects of highway wall guardrail includes a frame 47, the frame 47 includes a vertical beam 23 and a beam 56 connecting the adjacent vertical beams 23, and an engine is arranged on the beam 56 6. The engine 6 is connected to a gearbox 8, the gearbox 8 is connected to a transfer case 10, the transfer case 10 is connected to a hydraulic motor 11, the hydraulic motor 11 is connected to a hydraulic pump 12, and the beam 56 is also provided with an interface treatment glue storage tank 1, a cement thick slurry storage tank 2, a cement thin slurry storage tank 3 and an air compressor 15, the bottom of the vertical beam 23 is provided with a drive shaft 45, and the drive shaft 45 is connected There are tires 44, and the tires 44 are provided with a braking device 46;

[0031] The frame 47 is provided with a top surface treatment device 9 capable of performing defect treatment on the top of the wall-type ...

Embodiment 2

[0036] like Figure 1-10 As shown, the automatic processing device for surface defects of highway wall guardrail includes a frame 47, the frame 47 includes a vertical beam 23 and a beam 56 connecting the adjacent vertical beams 23, and an engine is arranged on the beam 56 6. The engine 6 is connected to a gearbox 8, the gearbox 8 is connected to a transfer case 10, the transfer case 10 is connected to a hydraulic motor 11, the hydraulic motor 11 is connected to a hydraulic pump 12, and the beam 56 is also provided with an interface treatment glue storage tank 1, a cement thick slurry storage tank 2, a cement thin slurry storage tank 3 and an air compressor 15, the bottom of the vertical beam 23 is provided with a drive shaft 45, and the drive shaft 45 is connected There are tires 44, and the tires 44 are provided with a braking device 46;

[0037] The frame 47 is provided with a top surface treatment device 9 capable of performing defect treatment on the top of the wall-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com