Pure solid wood cross-laminated wood

A technology of glued wood and solid wood, applied in sustainable buildings, walls, roofs, etc., can solve problems such as cracking, warping, and deformation, and achieve long service life, strong bearing capacity, and improved pressure-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

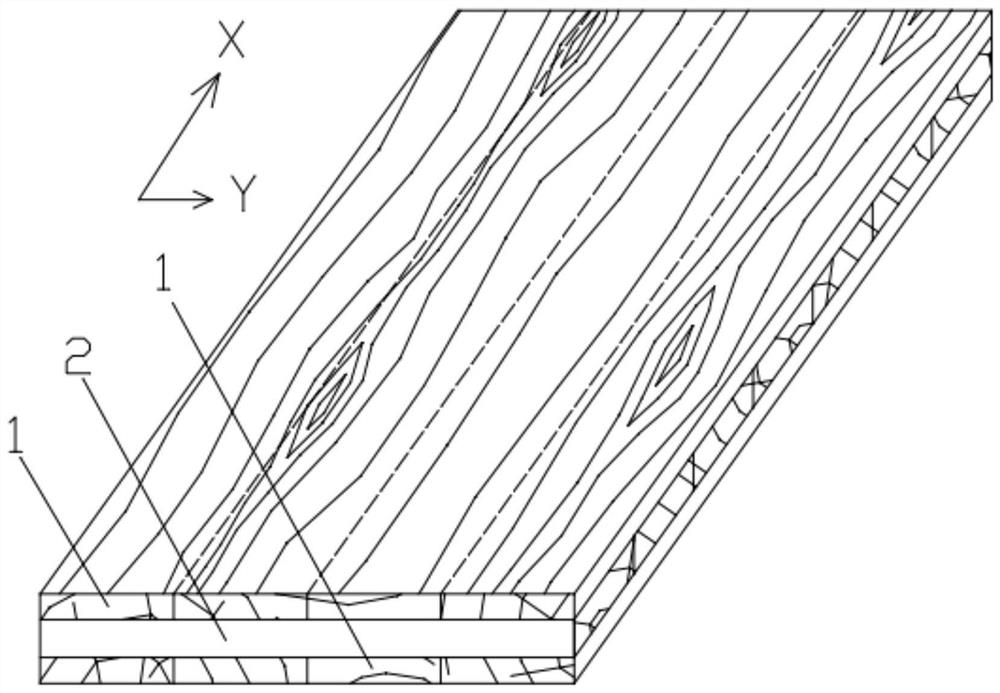

[0025] see figure 1 As shown, a pure solid wood orthogonal glued lumber comprises two parallel layers 1 and a transverse layer 2 located between the two parallel layers which are orthogonally assembled and glued to form orthogonal glued lumber, and the parallel layer 1 is the surface layer, The lateral layer is an intermediate layer.

[0026] The parallel layer 1 is a relatively hard solid wood layer, and the density and thickness of the upper and lower parallel layers 1 are basically the same; preferably, the upper and lower parallel layers 1 have the same density and the same thickness, and the parallel layer 1 is relatively For hard solid sawn timber or a splicing board of solid wood sawn timber with a harder specification, it should be emphasized that the splicing board of solid wood sawn timber with a hard specification is a splicing board of the same kind of hardwood.

[0027] The relatively hard solid wood adopts high-density birch, American oak, North American ash, et...

Embodiment 2

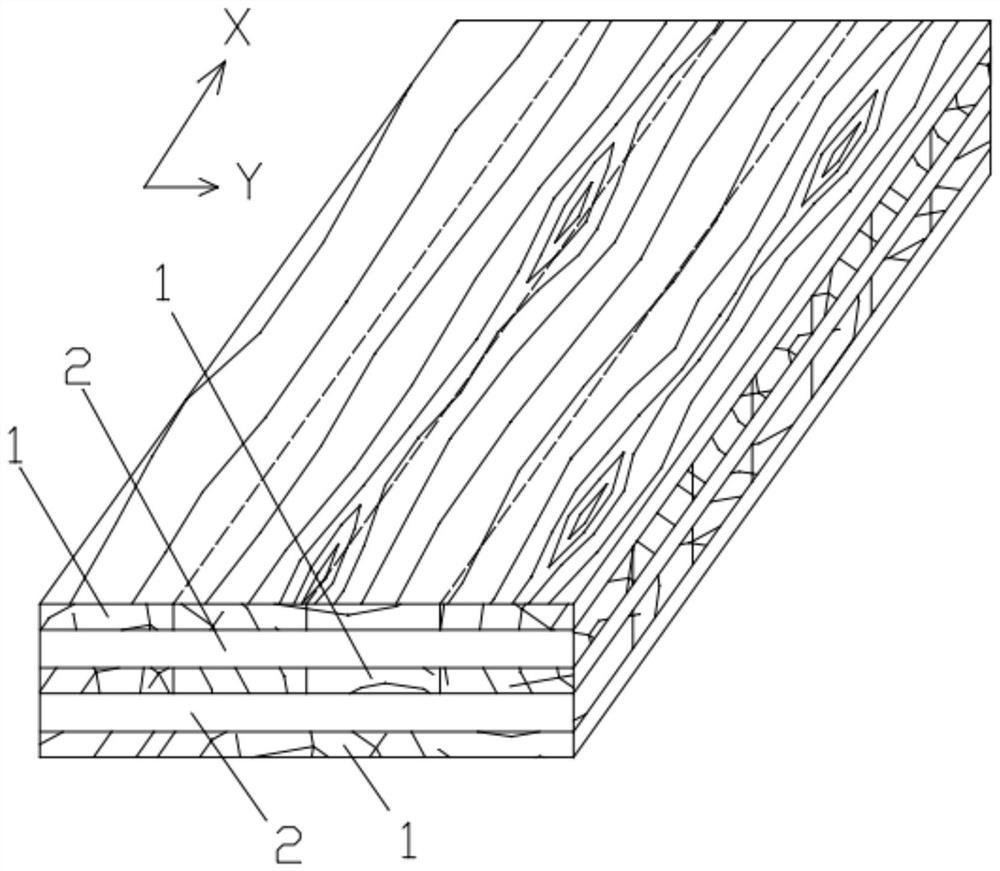

[0033] see figure 1 As shown, a pure solid wood cross-laminated lumber includes three layers of parallel layers 1 and a transverse layer 2 located between two adjacent parallel layers 1. Orthogonally assembled and glued to form cross-laminated wood, that is, two layers of transverse layers . The uppermost and lowermost parallel layer 1 is the surface layer, and the middle layer is the parallel layer 1, and the lateral layer 2 is located between the uppermost parallel layer 1 and the middle layer parallel layer 1, and the lateral layer 2 is located in the middle layer parallel Between layer 1 and the lowest layer parallel to layer 1.

[0034] The parallel layer 1 is a relatively hard solid wood layer, and the density and thickness of the upper and lower parallel layers are basically the same; preferably, the upper and lower parallel layers have the same density and the same thickness, and the parallel layers are relatively hard solid sawn timber Or a splicing board of hard wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap