Control system and method for nuclear energy steam extraction heat supply

A technology for steam extraction, heat supply and control system, which is applied in nuclear power generation, steam application, steam engine installation, etc. It can solve problems such as poor regulation characteristics, high exhaust pressure disturbance, and safety risk of steam turbine operation, so as to reduce disturbance and improve stability , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

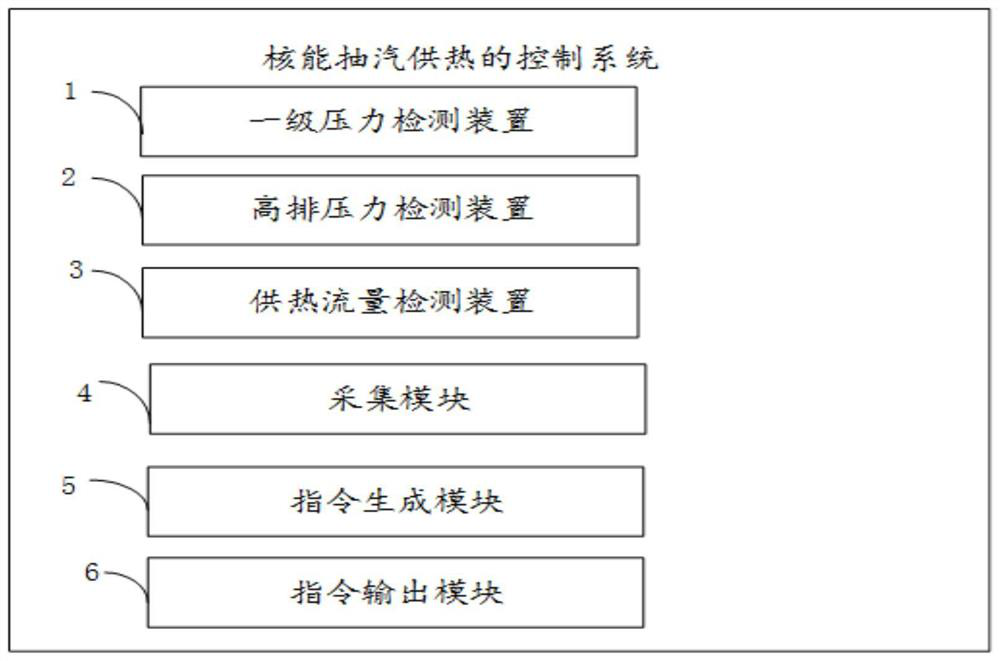

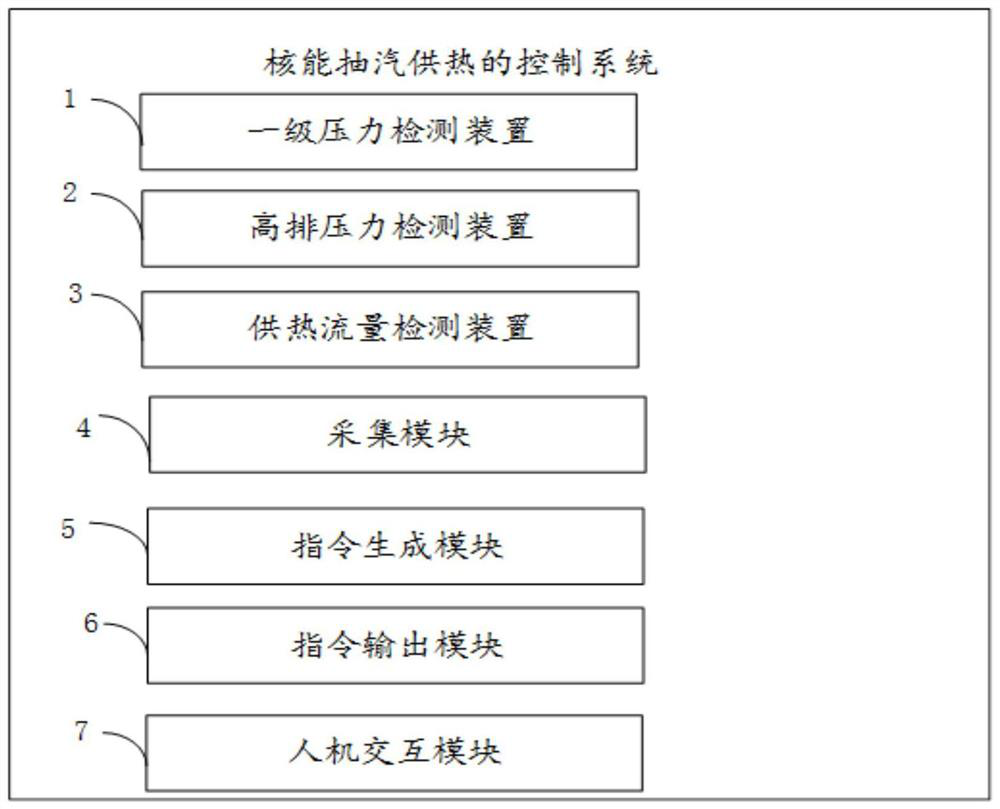

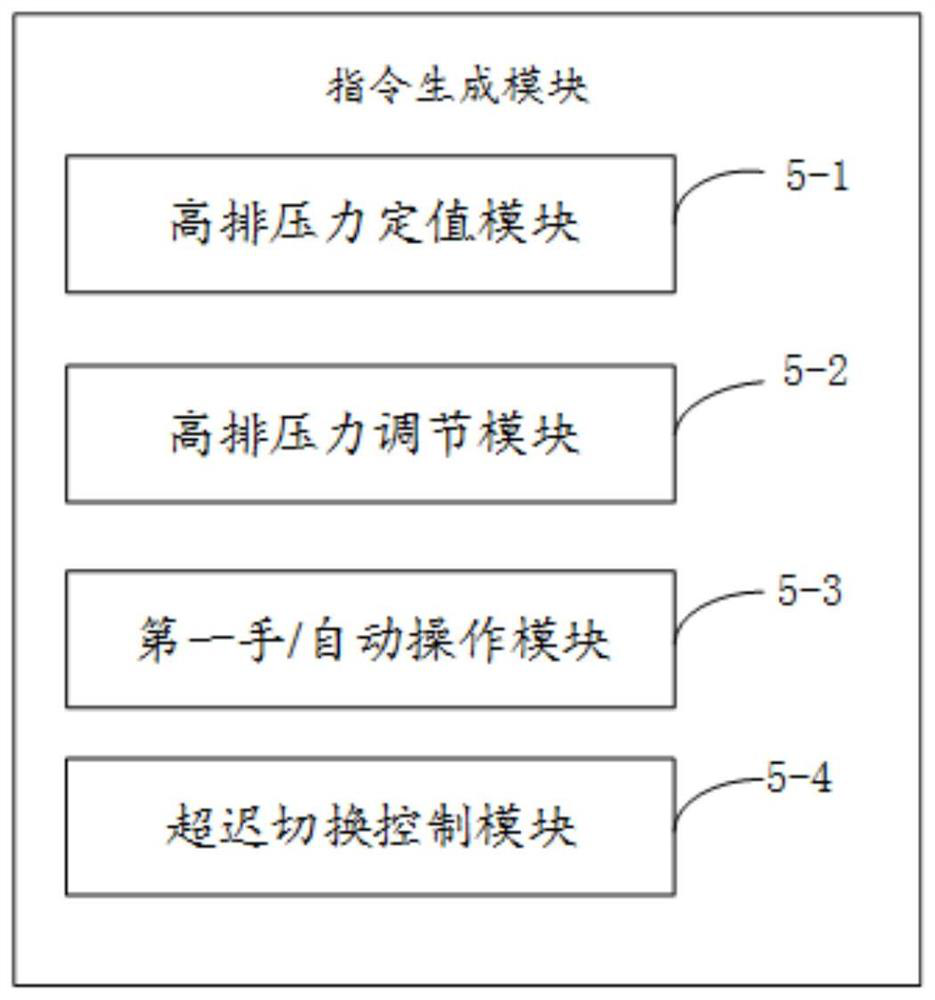

[0034] figure 1 The structure diagram of a control system for nuclear energy extraction and heating provided by the embodiment of the present disclosure, as shown in figure 1 As shown, the system includes: a primary pressure detection device 1, a high discharge pressure detection device 2, a heating flow detection device 3, a collection module 4, an instruction generation module 5 and an instruction output module 6;

[0035] The first-stage pressure detection device 1 is used to detect the first-stage pressure of the steam turbine to obtain the first-stage pressure signal;

[0036] The high exhaust pressure measuring device 2 is used to detect the exhaust pressure of the high pressure cylinder of the steam turbine to obtain an exhaust pressure signal;

[0037] The described steam extraction heat supply flow measuring device 3 is used to detect the extraction steam heat supply flow to obtain the extraction steam heat supply flow signal;

[0038] The collection module 4 is use...

Embodiment 2

[0073] Figure 8 A flow chart of a method for controlling nuclear energy extraction and heat supply provided according to an embodiment of the present application, such as Figure 8 As shown, the method may include:

[0074] Step 1: Obtain the first-stage pressure signal of the steam turbine, the exhaust steam pressure signal of the high-pressure cylinder of the steam turbine, the extraction steam heat supply flow signal and the fixed value of the extraction steam heat supply flow rate corresponding to the load demand of the heat network, and the preset value according to the design requirements of the steam turbine. Set high discharge pressure value;

[0075] Step 2: Determine the deviation between the extraction steam heat supply flow signal and the extraction steam heat supply flow constant value by using the extraction steam heat supply flow constant value and the extraction steam heat supply flow signal The pressure setting value and the exhaust steam pressure signal of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap