Method for quantitatively evaluating surface color defects of anodized aluminum alloy

A technology for aluminum alloy surface and color defects, which is applied in the direction of color/spectral characteristic measurement, optical test defects/defects, etc., can solve the problems that the severity of color defects cannot be effectively compared, and the analysis of color defects cannot be quantified, so as to facilitate the production process , high precision, and the effect of improving the quality and stability of aluminum materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: In this example, a blue 1050 aluminum alloy CTP plate with dark streaks in the middle of the sample to be tested is used as an example, and the method for quantitative evaluation of its color defects is as follows:

[0028] (1) Determine the position of the color defect on the surface of the sample to be tested by naked eye observation;

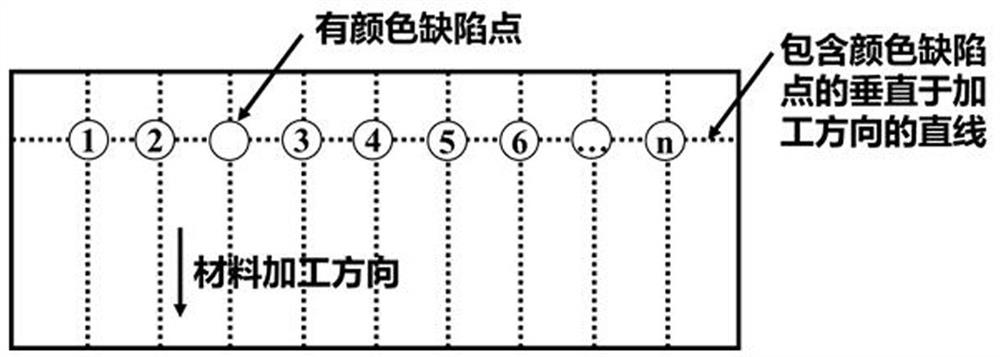

[0029] (2) Determine the straight line perpendicular to the processing direction of the material including the color defect points;

[0030] (3) Determine the test standard point and comparative analysis point by naked eye observation. The point adjacent to the color defect point is the test standard point, and the other selected points are the comparative analysis point. The defect point and the test standard point are respectively For one, select 7 comparative analysis points, and define them as comparative analysis point 1, comparative analysis point 2... comparative analysis point 7;

[0031] (4) Calculate the Lab value...

Embodiment 2

[0035]Embodiment 2: In this embodiment, the sample to be tested is taken as an example of a silver 1050 aluminum alloy CTP plate with wide white stripes on the surface. According to the method of the present invention, the color defect points, the comparative analysis points and the test standard sample points are determined, and the defect points and There is one test standard point each, and two comparative analysis points are selected, which are respectively defined as comparative analysis point 1 and comparative analysis point 2; the color space coordinate Lab value is calculated by spectrophotometry, and the grating diameter in spectrophotometry is 4 mm; Measure and calculate the object color tristimulus values X, Y, Z, color space coordinates L, a, and b values of the test standard points, color defect points, and contrast analysis points, as well as the color defect points, contrast analysis points, and test standard points. The color difference △E value, the calcula...

Embodiment 3

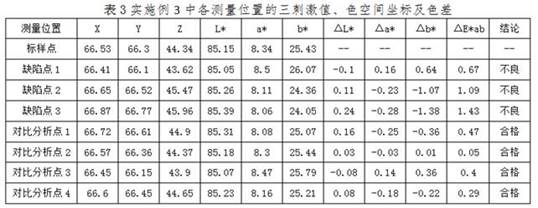

[0037] Example 3: In this example, the sample to be tested is taken as an example of anodized 5xxx series aluminum alloy yellow 3C parts with a light yellow area, and the color defect point, the comparative analysis point and the test standard sample are determined according to the method of the present invention. There are three adjacent color defect points, namely defect points 1, 2, and 3, one test standard point, and four comparative analysis points, namely comparative analysis points 1, 2, 3, and 4; Calculate the color space coordinate Lab value by spectrophotometry, the grating diameter in spectrophotometry is 4mm; measure and calculate the object color tristimulus values X, Y, Z, color space of the test standard point, color defect point, and contrast analysis point Coordinate L, a, b values and color defect points, the color difference △E value between the comparative analysis point and the test standard sample point, the calculation results are shown in Table 3; ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com