Method for evaluating performance of soft package lithium ion total battery by using button type half battery

A half-cell, lithium-ion technology, which is applied in the field of evaluating the performance of soft-pack lithium-ion full-cells, can solve the problems of lack of limited connection, reduced data reliability, etc., to achieve good practicability, saving test resources, and high test accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

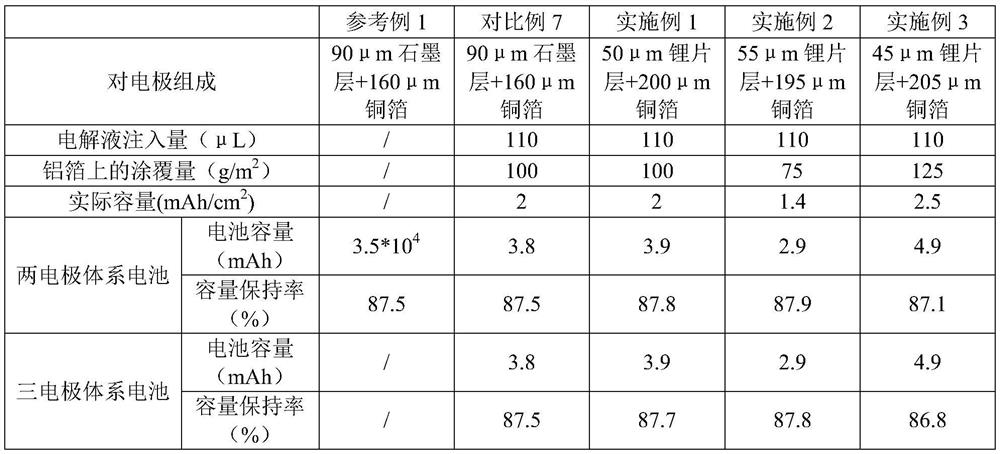

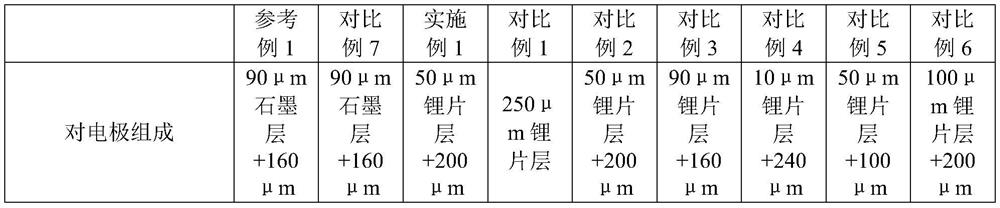

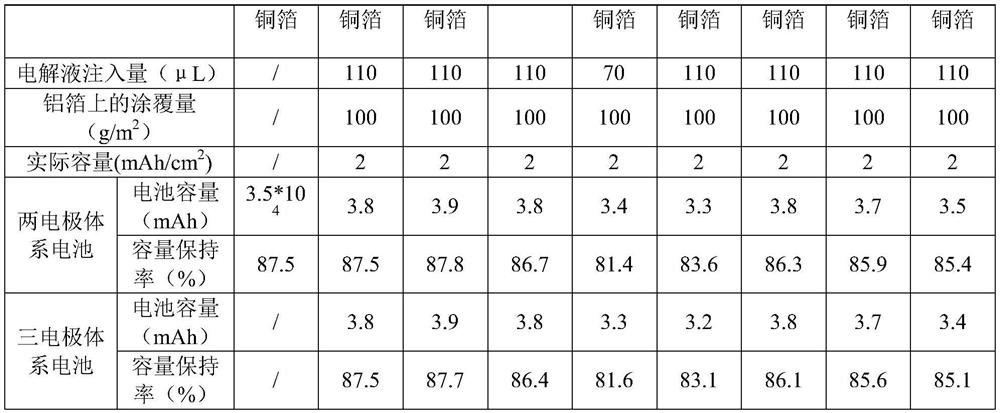

Embodiment 1

[0034] A) Production of positive electrode sheet: NCM811 ternary layered material: carbon nanotubes: polyvinylidene fluoride in a ratio of 85:7.5:7.5 and then coated on 18μm aluminum foil with a coating amount of 100g / m 2 , at 3.2g / cm after coating and drying 3 Compaction at the compaction density of 1.2 cm in diameter to make a circular positive electrode sheet;

[0035]B) Making a negative electrode sheet: a 50 μm thick lithium sheet layer and a 200 μm thick copper foil are pressed under an argon atmosphere of 40 standard atmospheres to make a circular negative electrode sheet with a diameter of 1.4 cm, which is used as a counter electrode;

[0036] C) Assemble a button-type half-cell with a two-electrode system in the order of negative electrode sheet, diaphragm, and positive electrode sheet, and inject 110 μL of electrolyte into the button-type half-cell; Assemble a button-type half-cell with a three-electrode system in the order of 3-electrode, and inject 110 μL of elect...

Embodiment 2

[0039] A) Production of positive electrode sheet: NCM811 ternary layered material: carbon nanotubes: polyvinylidene fluoride in a ratio of 80:10:10 and then coated on 20μm aluminum foil with a coating weight of 75g / m 2 , at 3.0g / cm after coating and drying 3 Compaction at the compaction density of 1.0cm in diameter to make a circular positive electrode sheet;

[0040] B) Making a negative electrode sheet: a 55 μm thick lithium sheet layer and a 195 μm thick copper foil are pressed under an argon atmosphere of 100 standard atmospheres to make a circular negative electrode sheet with a diameter of 1.2 cm, which is used as a counter electrode;

[0041] C) Assemble a button-type half-cell with a two-electrode system in the order of negative electrode sheet, diaphragm, and positive electrode sheet, and inject 110 μL of electrolyte into the button-type half-cell; Assemble a button-type half-cell with a three-electrode system in the order of 3-electrode, and inject 110 μL of electro...

Embodiment 3

[0044] A) Production of positive electrode sheet: NCM811 ternary layered material: carbon nanotube: polyvinylidene fluoride in a ratio of 90:5:5 and then coated on 15μm aluminum foil with a coating weight of 125g / m 2 , at 3.3g / cm after coating and drying 3 Compaction at the compaction density of 1.4cm in diameter to make a circular positive plate;

[0045] B) Making a negative electrode sheet: a 45 μm thick lithium sheet layer and a 205 μm thick copper foil are pressed under an argon atmosphere of 20 standard atmospheres to make a circular negative electrode sheet with a diameter of 1.6 cm, which is used as a counter electrode;

[0046] C) Assemble a button-type half-cell with a two-electrode system in the order of negative electrode sheet, diaphragm, and positive electrode sheet, and inject 110 μL of electrolyte into the button-type half-cell; Assemble a button-type half-cell with a three-electrode system in the order of 3-electrode, and inject 110 μL of electrolyte into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com