Self-adaptive thermal conductivity micro heat pipe array blade battery thermal management system and method

A technology of battery thermal management and micro-heat pipe, which is applied in the direction of secondary battery, battery temperature control, circuit, etc., can solve the problems of charge and discharge power decrease, internal resistance increase, affecting the discharge capacity and service life of blade batteries, etc., to reduce the temperature Fluctuation, small resistance, self-adaptive regulation of heat source temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better describe and understand the system structure and technical scheme of the present invention, the following embodiments of the present invention in conjunction with the accompanying drawings will be further described.

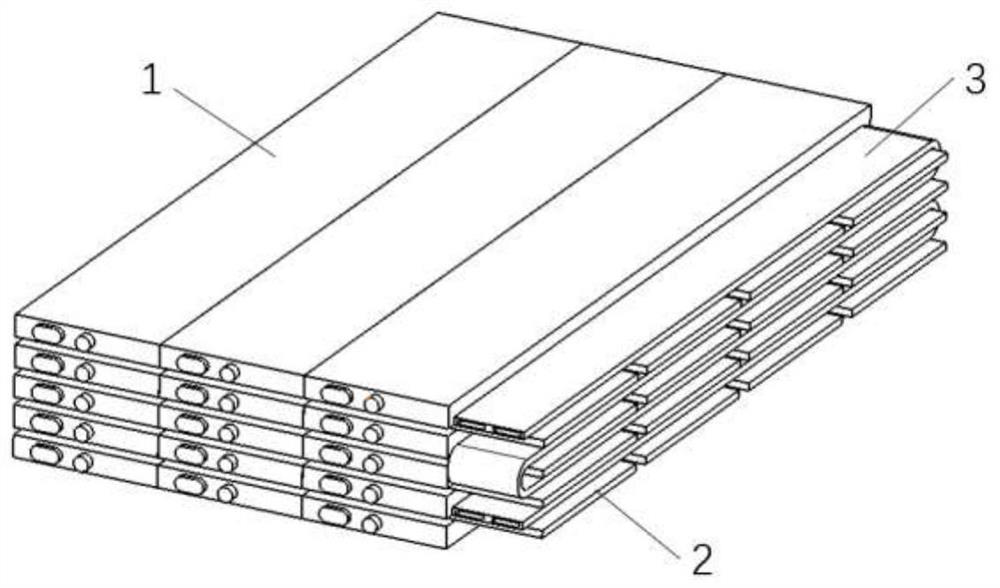

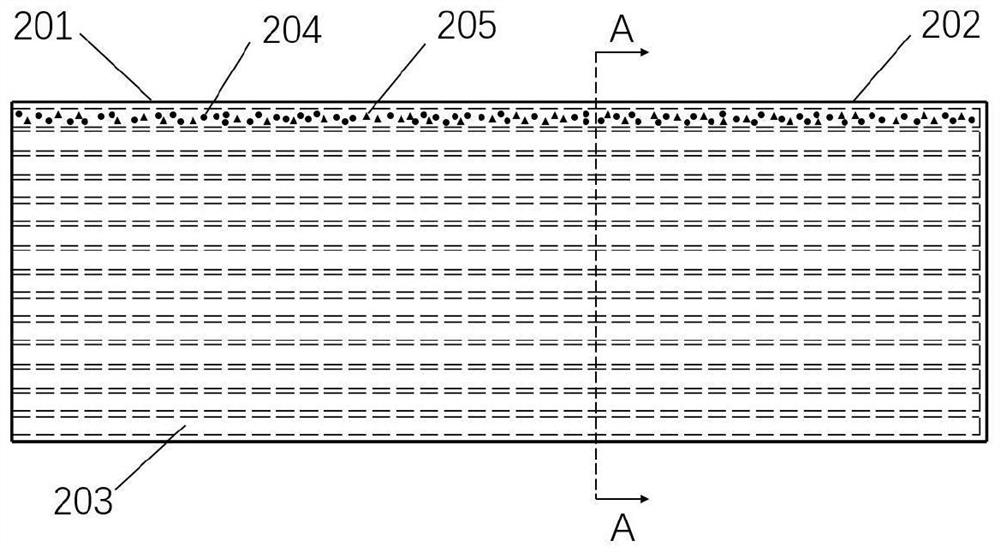

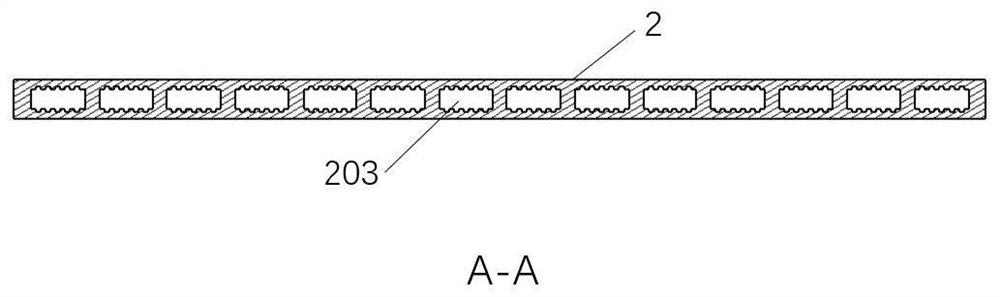

[0026] The present invention proposes an adaptive thermal conductivity microheor array blade battery thermal management system, such as Figure 1 Shown, comprising a blade battery pack 1, a microheat tube array 2 and a liquid cold plate 3. The blade battery pack 1 is composed of a plurality of blade batteries stacked in a rectangular arrangement, the blade battery pack 1 comprises at least two layers, each layer comprises at least one or more blade batteries. In an embodiment of the present invention, the blade battery pack 1 is arranged in the form of 5 layers of 3 pieces, a total of 15 blade batteries, the gap between the blade batteries of the same layer is filled with insulating thermal adhesive to reduce the contact thermal resistance, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com