Precise metal wire grid mesh manufacturing device

A technology for manufacturing devices and metal wires, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of high manual proficiency requirements, affecting the strength of welding joints, and fast cooling speed, so as to reduce cooling speed and improve Strength, the effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

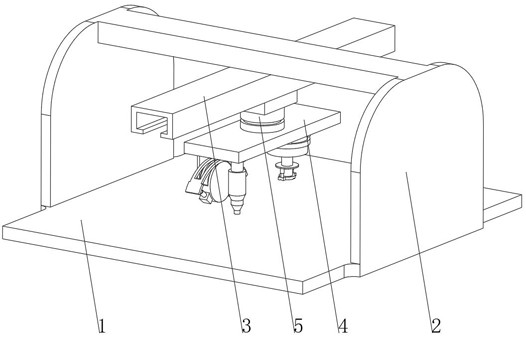

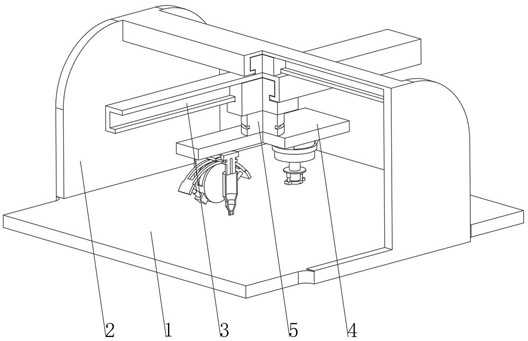

[0040] see Figure 1-Figure 4 , the present invention provides a technical solution: a precision wire grid manufacturing device, specifically comprising:

[0041] A workbench 1, the top of the workbench 1 is fixedly connected with a support frame 2, and the top of the support frame 2 is fixedly connected with a cross guide rail 3;

[0042] Welding device 4, the welding device 4 is arranged above the workbench 1, and the top of the welding device 4 is fixedly connected to the bottom of the electronic slider inside the cross guide rail 3 through the rotating table 5;

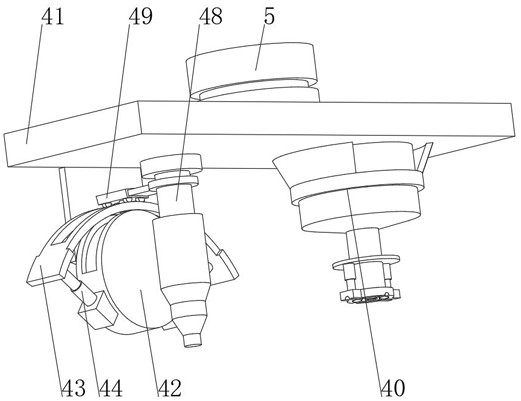

[0043]Welding device 4 comprises:

[0044] A fixed seat 41, the bottom of the fixed seat 41 is fixedly connected with a fixed plate 42 through a bracket, the top of the fixed plate 42 is fixedly connected with an arc-shaped guide rail 43, and both ends of the arc-shaped guide rail 43 are fixedly connected with a first telescopic rod 44;

[0045] Rotating disk 45, the rotating disk 45 is arranged inside the fixed...

Embodiment 2

[0053] see Figure 1-Figure 6 On the basis of Embodiment 1, the present invention provides a technical solution: the powder spreading device 40 includes a material storage box 401, the bottom of the material storage box 401 is connected with a discharge pipe 402, and the inner wall of the discharge pipe 402 is slidably connected with a sliding pipe 403, The bottom of the sliding pipe 403 extends to the outside of the discharge pipe 402 and is fixedly connected with an extrusion head 404. Both ends of the top of the extrusion head 404 are fixedly connected with electric push rods 405. The inner wall of the sliding pipe 403 is provided with a spiral feeding roller 406, and the spiral feeding roller The top of 406 extends to the inside of the material storage box 401 and is fixedly connected with the second telescopic rod 407. The top of the second telescopic rod 407 is fixedly connected with the drive shaft of the drive motor 408. The top of the material storage box 401 runs thro...

Embodiment 3

[0055] see Figure 1-Figure 7 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the extrusion head 404 includes an extrusion seat 4041, the bottom of the extrusion seat 4041 is provided with an extrusion groove 4042, and the inner wall of the extrusion groove 4042 is slidingly connected with Adapting die 4043, the bottom of the adapting die 4043 is provided with an adapting groove 4044, the top of the extrusion seat 4041 is fixedly connected with the bottom of the sliding tube 403, the adapting groove 4044 is matched with the welding part of the metal grid, and the upper part of the adapting die 4043 A through hole matching the screw feeding roller 406 is provided, an elastic buckle is provided between the adapter die 4043 and the inner wall of the extrusion groove 4042, and an extrusion head 404 is provided, which can pass through the adapter die inside the extrusion head 404 4043 adapts to metal grids with different mesh sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com