Full-automatic trepanning and hole grinding machine

A fully automatic, hole grinding technology, applied in the direction of grinding frames, grinding machine parts, grinding machines, etc., can solve the problems of high processing cost, low processing efficiency, difficult milling of engraving machines, etc., to reduce physical loss, Improve production quality and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

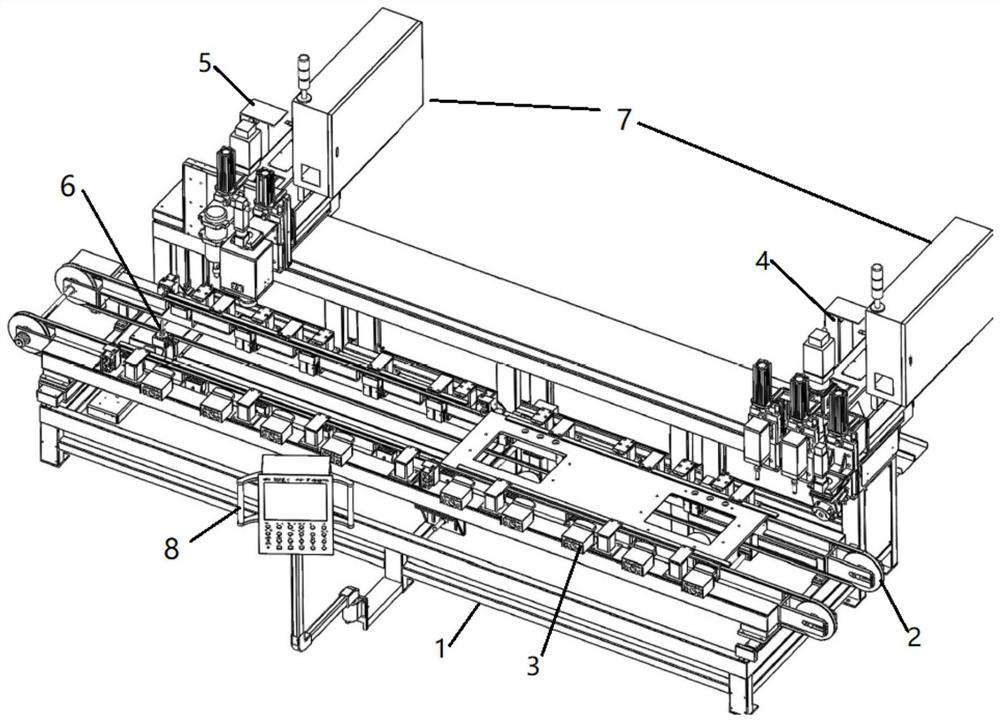

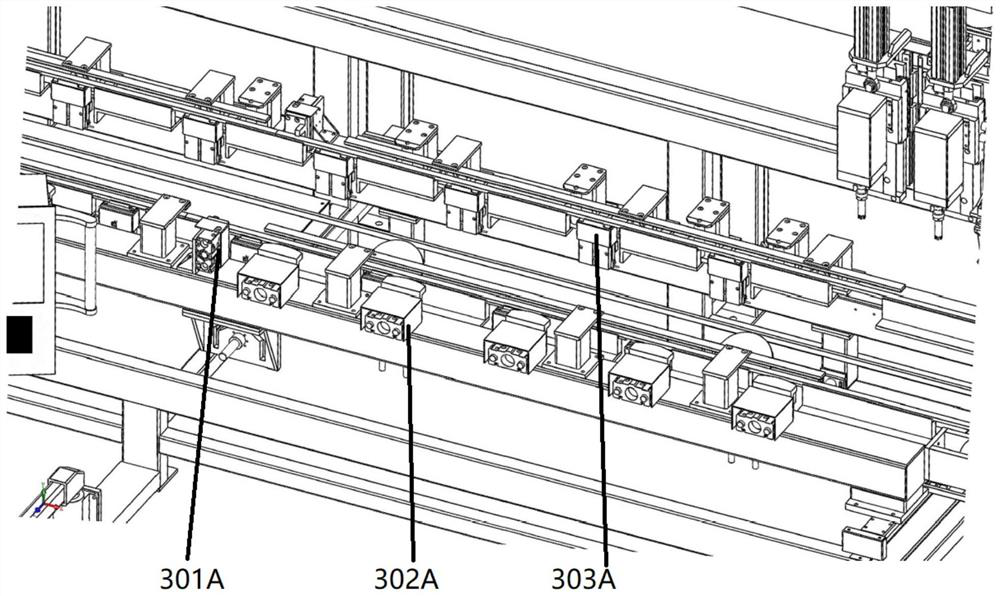

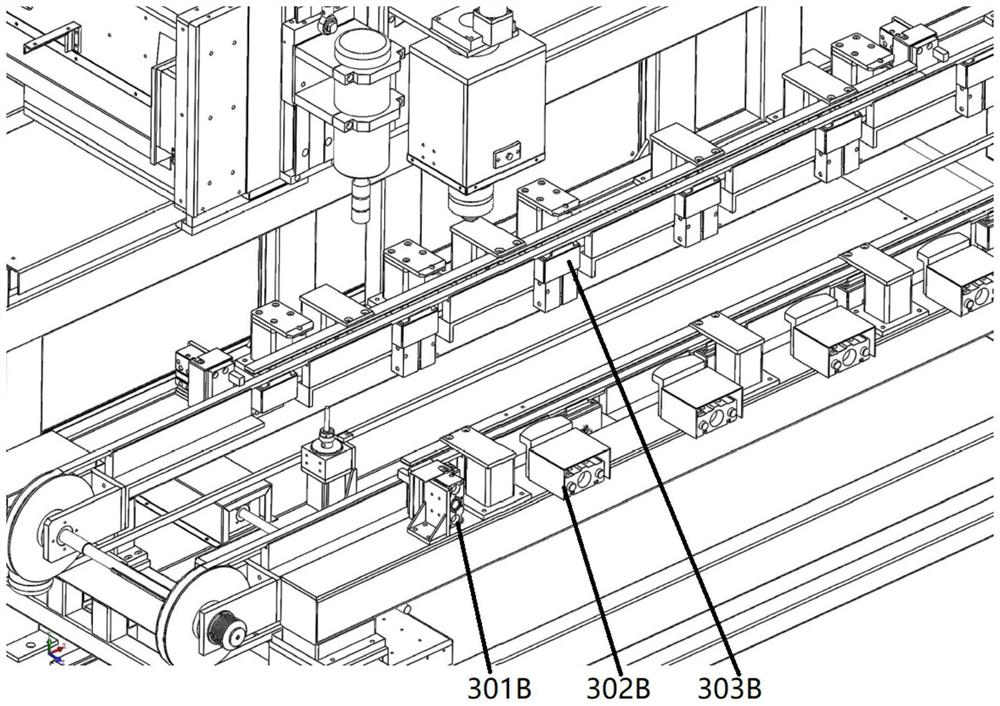

[0031] Such as Figure 1-8 As shown, the fully automatic drilling and grinding machine includes: chassis 1, conveying part 2, positioning and clamping part 3, first machine head part 4, second machine head part 5, bottom drilling part 6, main electrical box Part 7 and control box part 8; the conveying part 2 is installed on the chassis 1, and the positioning and clamping part 3 is installed on the conveying part 2; the first machine head part 4, the second machine head part 5, the bottom hole part 6, The main electric box part 7 and the control box part 8 are all installed on the chassis 1, and the main electric box part 7 is respectively connected with the conveying part 2, the positioning and clamping part 3, the first head part 4, the second head part 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com