Oversized glass lifting equipment

A glass and ultra-large technology, applied in the direction of glass production, transportation and packaging, load hanging components, etc., can solve the problems of large glass area, large safety risks, and heavy weight, so as to achieve high safety, reduce safety hazards, and reduce invisibility The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

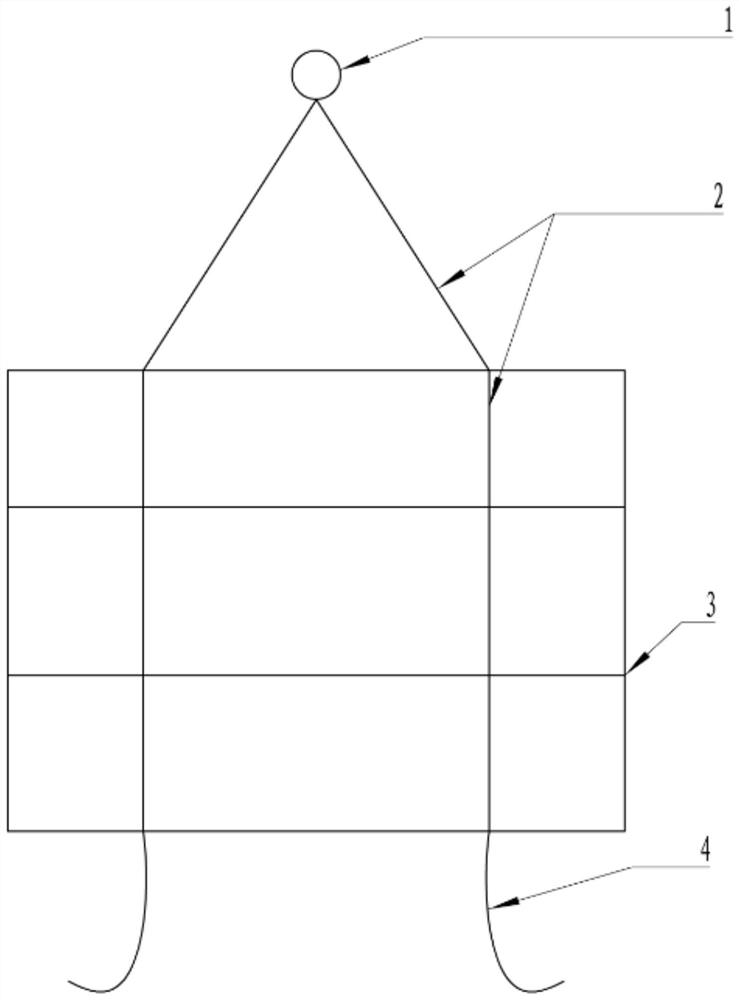

[0026] Embodiment one is basically as attached figure 1 As shown, a super-large glass lifting equipment includes a winch, a lifting wheel set, a transfer frame and a lifting frame; the hoist and the lifting wheel set are used to lift the glass to the transfer frame, and the lifting frame A suction cup set, the lifting frame absorbs and transfers the glass through the suction cup set.

[0027] Specifically, the hoist is fixed at the upper structural position where the glass floor needs to be installed, and the hoist is an electric hoist with a lifting capacity of 2T, and the hoist is provided with a bracket to form a force bar. The hoisting wheel set includes a pulley, a steel wire rope, a waist rope 3 and a glass suspender 2, one end of the steel rope is connected to the winch along the support, and the other end of the steel rope is provided with a hook 1; the glass suspender 2 is provided with two, two Two glass suspenders 2 are attached to the target glass, the upper end o...

Embodiment 2

[0033] The difference between Embodiment 2 and Embodiment 1 is that Embodiment 2 also includes a traction controller and a traction device. In this embodiment, there are four cable wind ropes, which are respectively used for traction in four directions on both sides of the two ends of the glass. , the upper end of the cable wind rope is connected with the glass sling, the lower end of the cable wind rope is respectively provided with a traction device for pulling the cable wind rope in each direction, the traction controller is wirelessly connected with each traction device, and the traction controller is used to control The traction device pulls the cable wind ropes in all directions to stabilize the glass and prevent the glass from tilting or colliding with the wall. The mechanical traction of the cable wind ropes is more accurate and safer than human judgment with the naked eye. Insurance.

Embodiment 3

[0035] The difference between the third embodiment and the second embodiment is that the third embodiment also includes a light strip, the light strip is attached to the top surface of the glass, the light source faces directly below the glass, and emits light to the inside of the glass through the front facing down, and the light strip is attached to the top surface of the glass. The outer surface forms a contour light, which is convenient for users to determine the orientation and orientation of the glass during night construction, and speeds up the work progress during actual construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com