PP plastic antifogging sheet and preparation process thereof

A preparation process and technology of anti-fog sheet, which is applied in the direction of coating, special surface, and device for coating liquid on the surface, etc., which can solve the problem of high production cost of PP anti-fog sheet, which cannot achieve the first-class anti-fog and anti-fog effect Poor and other problems, to achieve the best anti-fog effect, improve the molding effect, improve the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

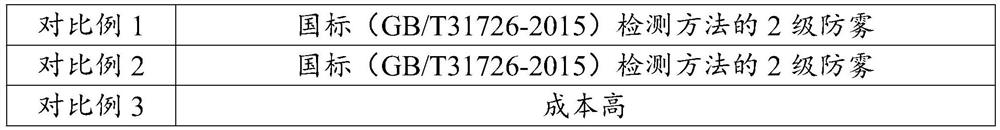

Examples

Embodiment 1

[0030] The present invention provides a technical solution: a PP plastic anti-fog sheet, comprising an anti-fog sheet and an anti-fog coating on the surface of the anti-fog sheet, and the extrusion formula of the anti-fog sheet includes the following components Proportion by weight: 0.5 part by weight of PP-450E raw material, 0.5 part by weight of PP-5015 recycled material, the anti-fog coating formulation of the anti-fog coating on the surface of the anti-fog sheet includes the following parts by weight of the components : 1.5 parts by weight of antifogging agent, 3 parts by weight of water, 3 parts by weight of alcohol.

[0031] In the production process that the PP plastic anti-fog sheet material obtained above is applied to the plastic anti-fog sheet material, the following preparation process steps are included:

[0032] S1: prepare the mixed material, put the pp-450E raw material and the pp-5015 reclaimed material into the mixer according to the ratio of 1:1, and stir an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com