Method for repairing positive active material of lead-acid battery

A positive active material, lead-acid battery technology, applied in the direction of secondary battery repair/maintenance, secondary battery, electrolyte/reactant regeneration, etc., can solve problems such as limited effect, prolong service life, delay softening and falling off process, The effect of reducing the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method of cyclic charging and discharging of D-450 flooded tractor lead-acid battery is as follows:

[0037] Discharge: 112A discharge, discharge 3h.

[0038] Charging: 94A charging for 3 hours, 22A charging for 6 hours;

[0039] The above is one cycle (charge 9 discharge 3 procedures), record the relationship between the discharge capacity and the number of cycles.

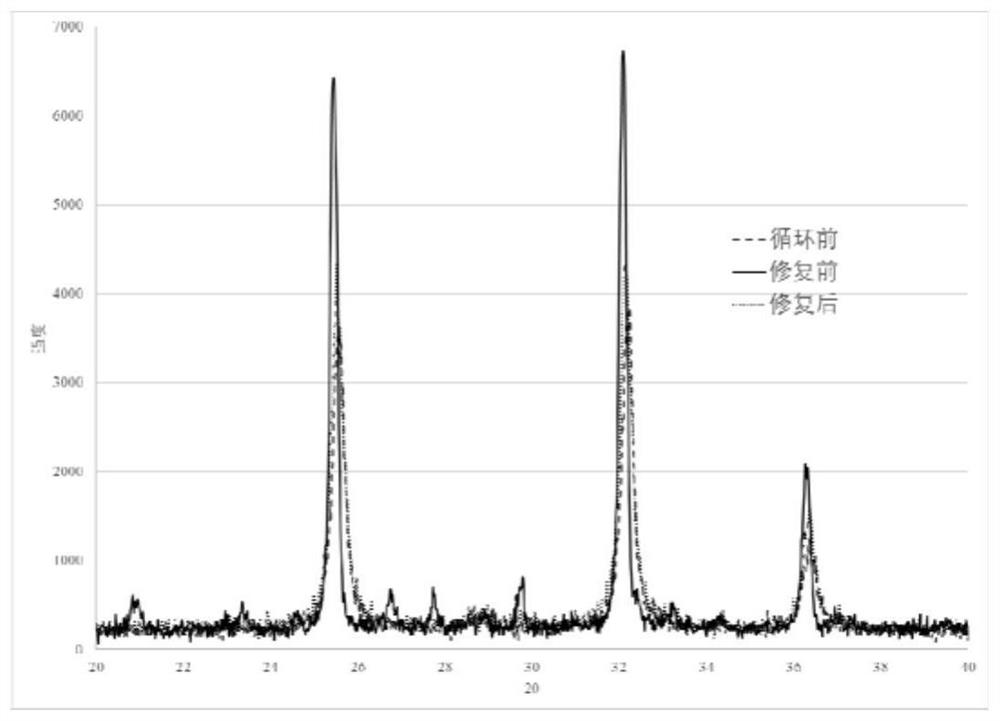

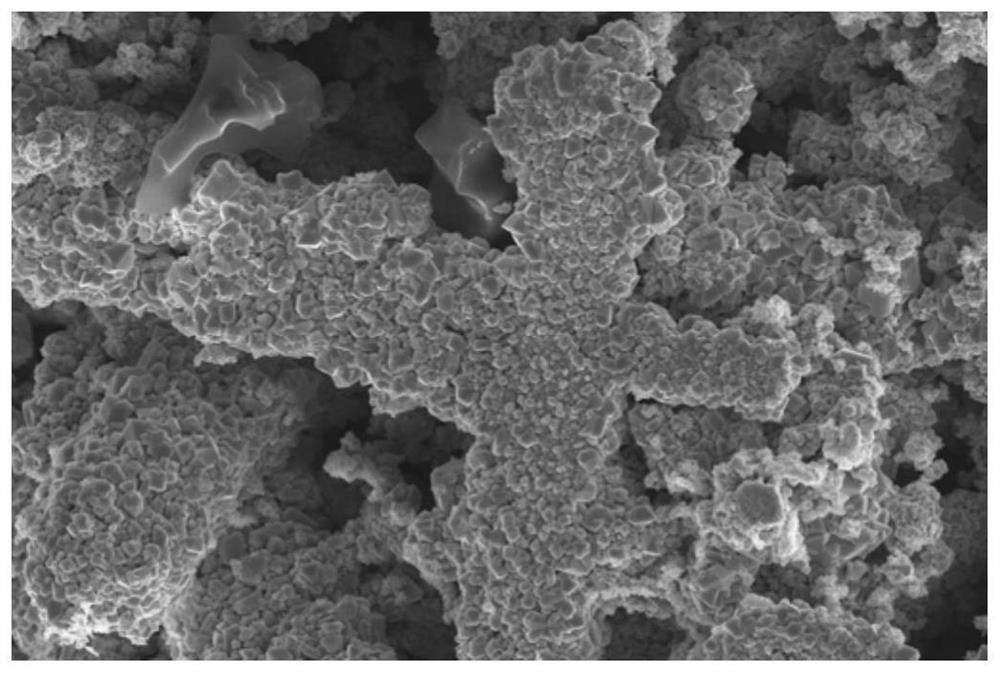

[0040] The SEM morphology analysis of the cathode active material before the cycle was obtained. figure 2 .

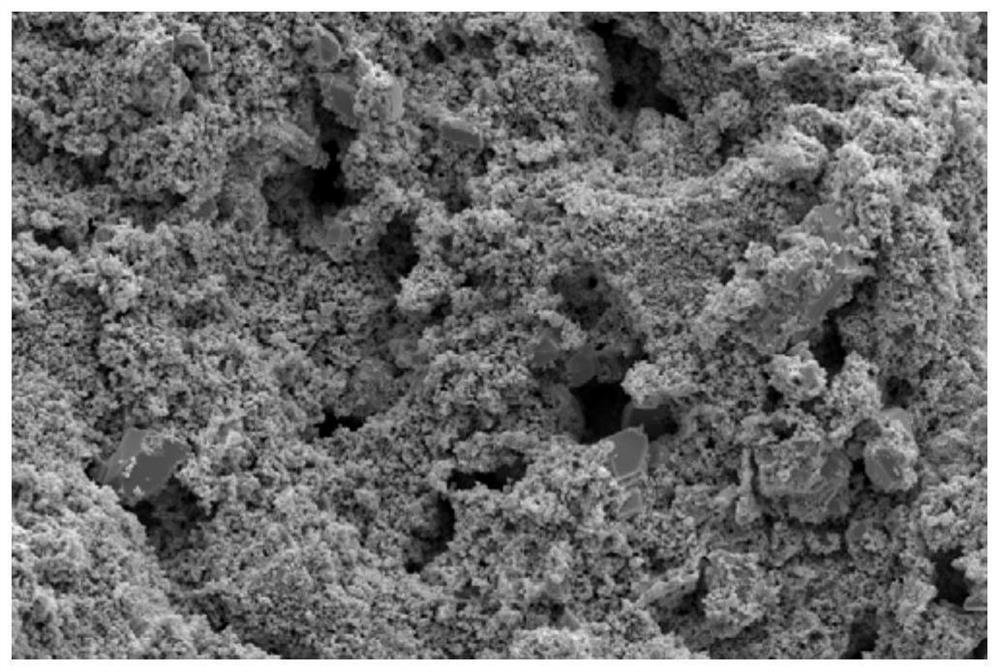

[0041] After every 49 cycles, 90A discharge was carried out, and the termination voltage was 1.7V. When the time discharge time was 4.5h, the battery was fully charged, and the positive electrode active material at this time was analyzed by SEM. image 3 .

[0042] The method is: charge 45A to 2.4V, then charge 22.5A for more than 10h, and then enter the repair procedure:

[0043] (1) Complete discharge: firstly discharge the above-mentioned lead-acid battery to be repaired with a small c...

Embodiment 2

[0053] Prepare the traditional reference 6-DZM-10 lead-acid battery for electric vehicles, the positive active material does not add tetrabasic lead sulfate, and prepare another set of reference batteries, and add 1.0% tetrabasic lead sulfate crystal to the positive active material The above-mentioned batteries are charged and discharged cyclically together, and the method is as follows:

[0054] Discharge: 5A discharge, discharge termination voltage.

[0055] Charging: 2A / 14.4V constant current voltage limiting for 6h, 1A charging for 1h;

[0056] The above is one cycle, and the relationship between the discharge capacity and the number of cycles was recorded.

[0057] After 200 cycles, it was found that the capacity of the traditional battery without adding tetrabasic lead sulfate significantly decreased, and at this time, the method was repaired according to the present invention.

[0058] (1) Complete discharge: firstly discharge the above-mentioned lead-acid battery to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com