Special extrusion bulking machine for processing plant meat

An extrusion extruder and meat processing technology, which is applied in plant protein processing, textured treatment, protein food processing, etc., can solve the problems of heat loss and insufficient cross-linking of materials, so as to reduce power consumption and heat Loss, improve the effect of extrusion puffing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

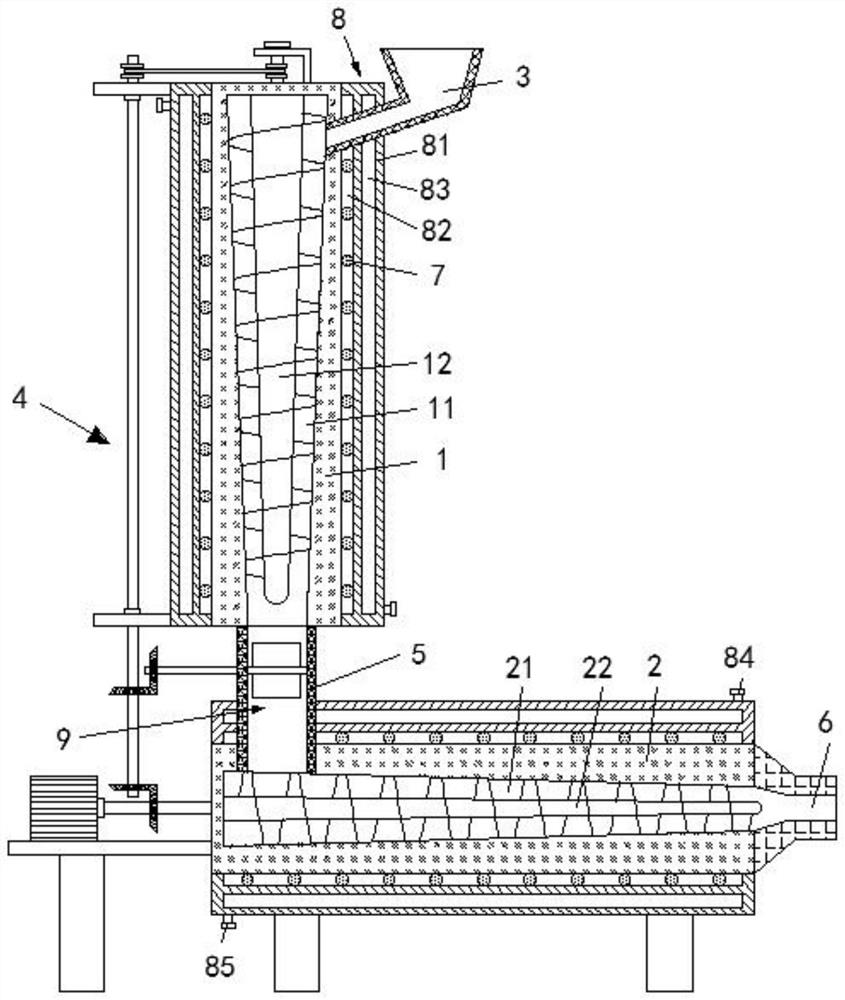

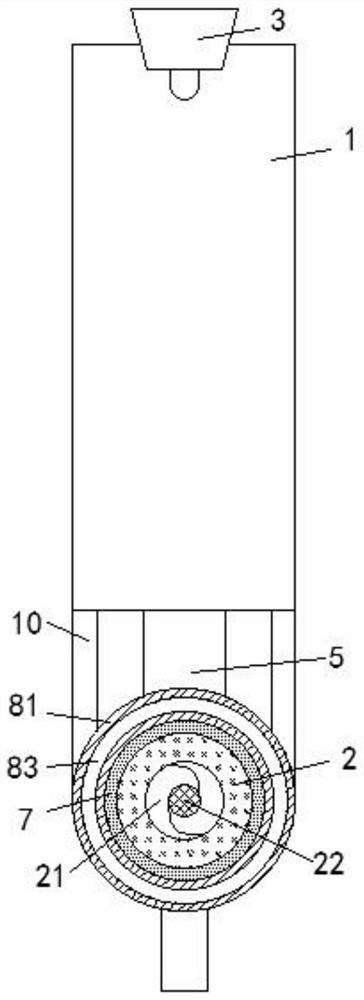

[0031] Refer to the attached Figure 1-4 , a special extrusion extruder for vegetable meat processing, comprising a first extrusion cylinder 1 and a second extrusion cylinder 2, the first extrusion cylinder 1 is vertically arranged above the side of the second extrusion cylinder 2 , and a feeding hopper 3 is connected to the top of one side of the first extrusion cylinder 1. The first extrusion cylinder 1 is provided with a first puffing cavity 11, and the first puffing cavity 11 is rotatably connected with a vertical first puffing cavity 11. A conical screw 12, the second extrusion barrel 2 is provided with a second expansion cavity 21, and the second expansion cavity 21 is rotatably connected with a horizontal second conical screw 22, the first conical screw 12 and the second conical screw 22 are driven by the driving mechanism 4, the bottom of the first puffing cavity 11 is communicated with the top of one side of the second puffing cavity 21 through the discharge pipe 5, a...

Embodiment 2

[0033] Refer to the attached figure 1 and 2, in order to improve the extrusion and puffing effect, it is more optimal that the diameter of the first conical screw 12 and the inner diameter of the first puffing cavity 11 gradually decrease from top to bottom, and the diameter of the first conical screw 12 The spiral blade is slidably connected to the inner wall of the first extruding cavity 11 , and the diameter of the second conical screw 22 and the inner diameter of the second extruding cavity 21 are from the end close to the discharge pipe 5 to the end close to the extrusion die 6 . One end is gradually reduced, and the helical blade on the second conical screw 22 is slidably connected with the inner wall of the second expansion cavity 21 . Through the arrangement of this structure, as the material progresses, the shear force received by the material during the extrusion and puffing process increases gradually, which increases the cross-linking between the materials, and ma...

Embodiment 3

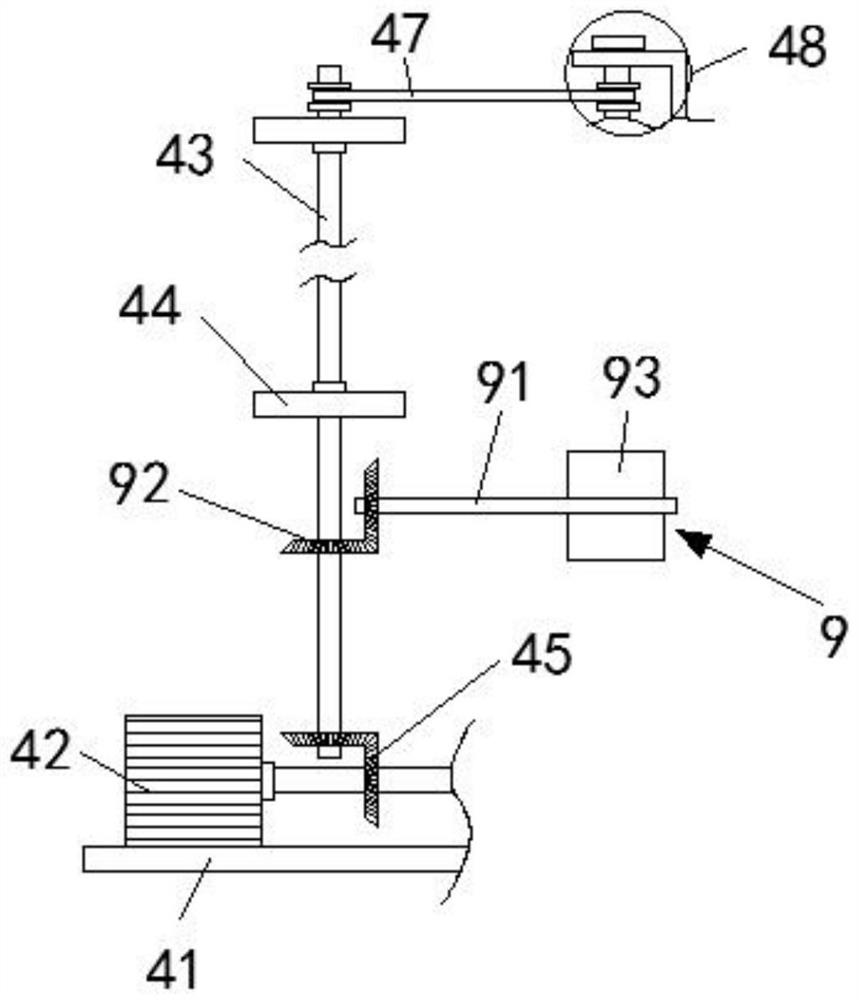

[0036] Refer to the attached figure 1 and 3 , in order to facilitate the rotation of the first conical screw 12 and the second conical screw 22, it is more optimal that the driving mechanism 4 includes a motor 42 fixed on the outer side of one end of the second extrusion cylinder 2 through a support plate 41 and a vertical The transmission rod 43 is arranged in parallel on the outer side of the first extrusion cylinder 1, the upper and lower ends of the outer side of the first extrusion cylinder 1 are fixed with mounting plates 44, and the transmission rod 43 rotates with the two mounting plates 44 Connecting and passing through the two mounting plates 44, the motor 42 drives the second conical screw 22 and the transmission rod 43 through the intermeshing first bevel gear set 45, and the two intermeshing bevel gears are respectively sleeved on the output shaft of the motor 42 and the lower end of the transmission rod 43, and the output shaft of the motor 42 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com