Circulating liquid PH intelligent control device for ammonium sulfate production

A technology of intelligent control and circulating liquid, applied in the direction of ratio control, ammonium sulfate, chemical variable control, etc., can solve the problems of ammonia inhalation, physical and mental health injury of employees, high labor intensity, etc., and achieve the effect of increasing filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

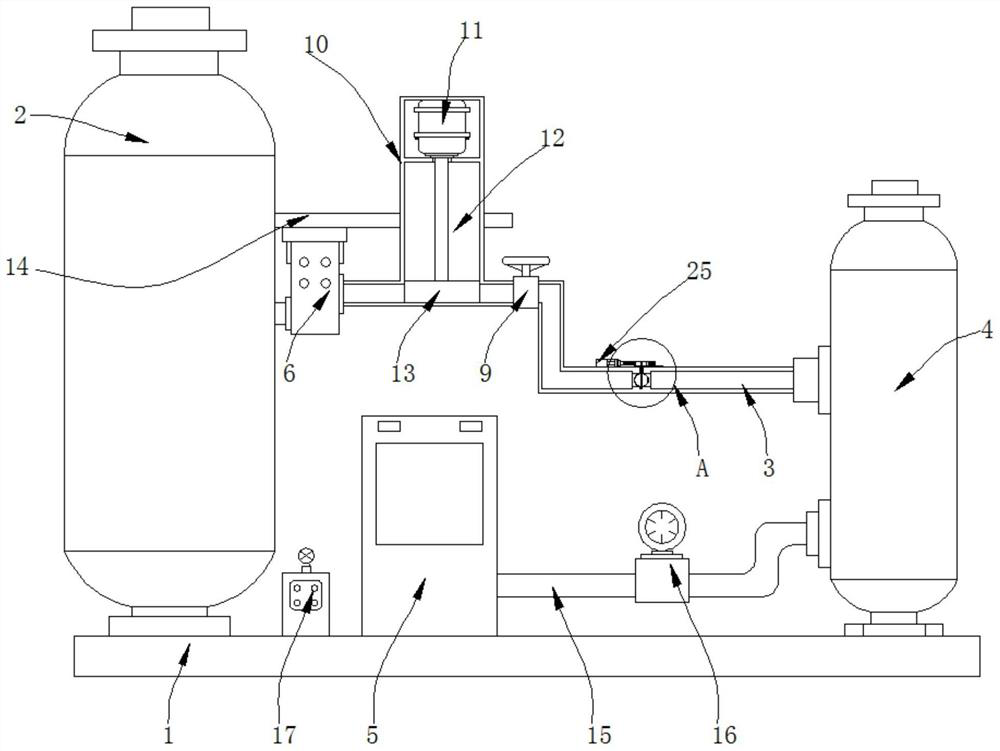

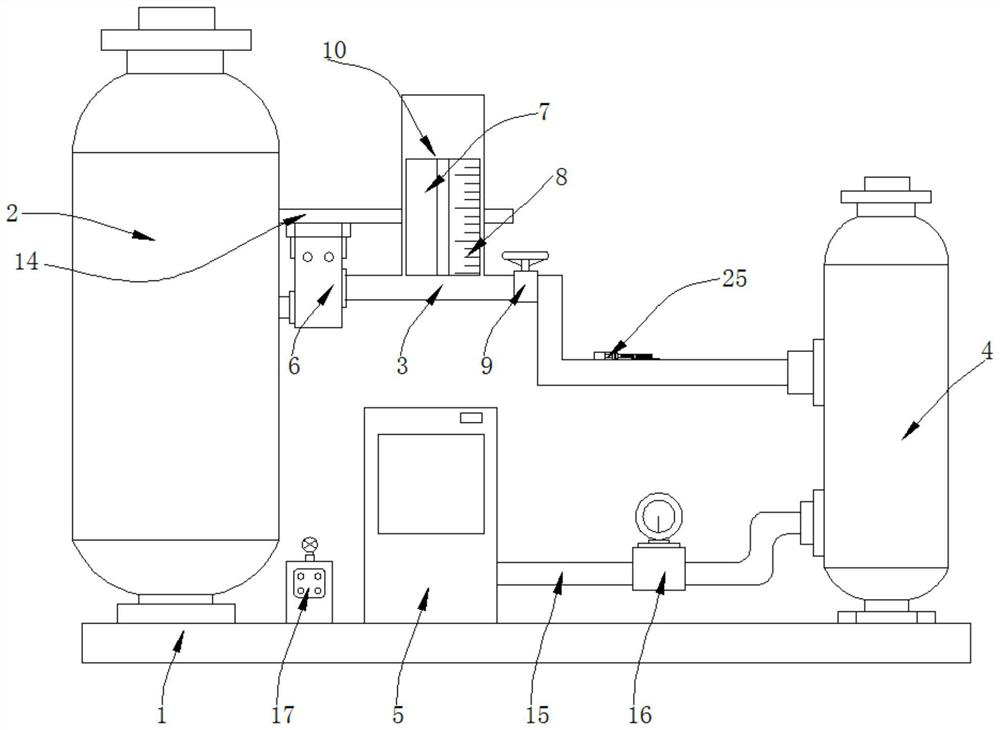

[0024] Example 1, as Figure 1-2 As shown, the present invention provides a technical solution: a circulating liquid pH intelligent control device for ammonium sulfate production, comprising a bottom plate 1 and a flow regulating mechanism 25, the top of the bottom plate 1 is provided with an acid storage container 2, and the bottom plate 1 is far away from the acid storage container. One side of 2 is provided with a circulating liquid overflow device 4, one side of the acid storage container 2 is provided with a fixing frame 14, and the bottom end of the fixing frame 14 is provided with an acid pump 6, and the input end of the acid pump 6 is connected with the acid storage container 2. Connected, the output end of the acid pump 6 is provided with a conveying pipe 3 that is connected with the input end of the circulating liquid overflow device 4, and the top of the conveying pipe 3 is provided with an acid adding frame 10 that runs through the fixing frame 14, and the inside of...

Embodiment 2

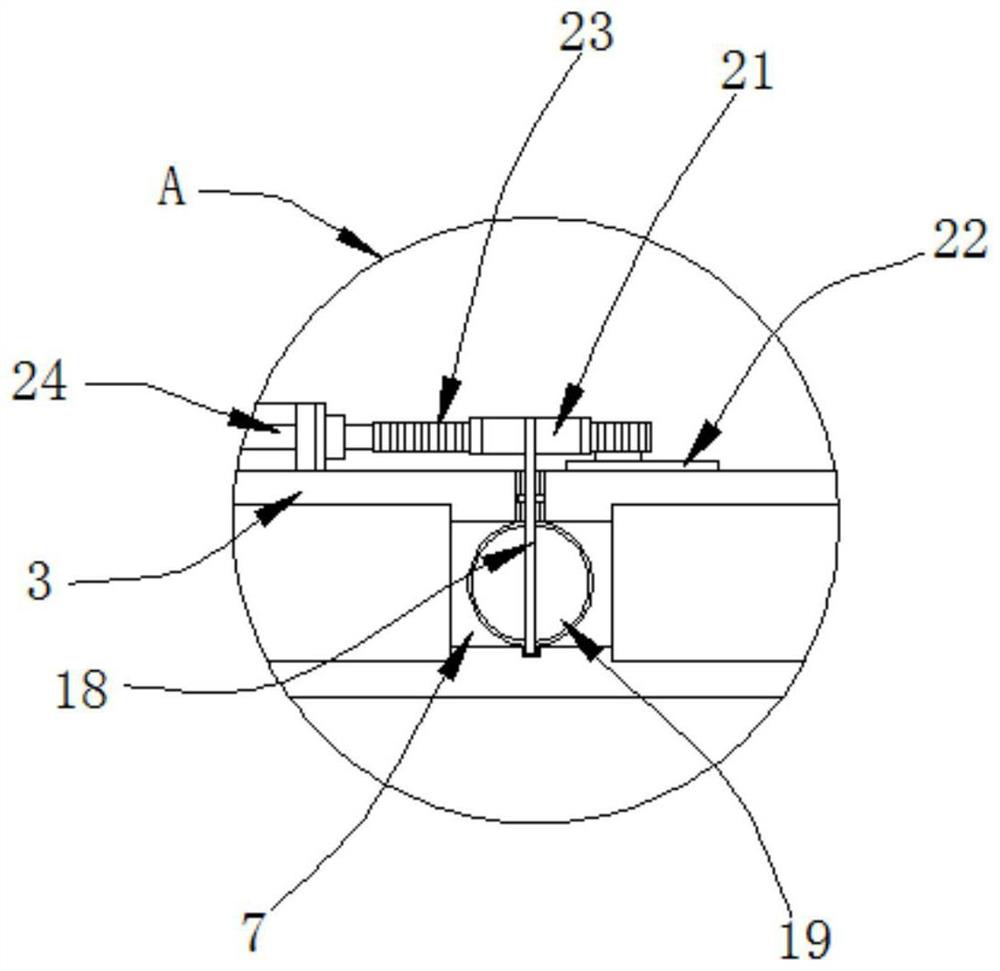

[0025] Example 2, as Figure 1-4 As shown, the present invention provides a technical solution: a circulating liquid pH intelligent control device for ammonium sulfate production, including the outer wall of the conveying pipe 3 is provided with a first valve 9, and the conveying pipe 3 is set close to the side of the circulating liquid overflow device 4 There is a flow adjustment mechanism 25 for controlling the flow. The flow adjustment mechanism 25 includes a sealing groove 26 and an inclined block 20. An observation window 7 is provided inside the conveying pipe 3, and two ends of the sealing groove 26 are provided with inclined blocks 20. The sealing groove The inside of 26 is installed with the rotating shaft 18 through the bearing, and the outer wall of the rotating shaft 18 is provided with a sealing arc block 19, the outer wall of the sealing arc block 19 matches the outer wall of the sealing groove 26, and the outer wall of the rotating shaft 18 is provided with a gea...

Embodiment 3

[0026] Example 3, as Figure 1-5 As shown in the figure, the present invention provides a technical solution: a circulating liquid pH intelligent control device for ammonium sulfate production, comprising an ammonium sulfate crystallizer 5 arranged at the top of the bottom plate 1, and the ammonium sulfate crystallizer 5 is located at the bottom plate 1 and the circulating liquid is full Between the outer walls of the flow device 4, the output end of the circulating liquid full flow device 4 is provided with a connecting pipe 15 which is connected with the input end of the ammonium sulfate crystallizer 5, and the interior of the connecting pipe 15 is provided with a high-precision pH value detector 16. A PLC control system 17 is provided at the top of the PH value detector 16, the output end of the high-precision pH value detector 16 is electrically connected with the input end of the PLC control system 17 through wires, and the output end of the PLC control system 17 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com