Petrochemical oil-water efficient separation device

A petrochemical and separation device technology, applied in grease/oily substance/float removal device, separation method, liquid separation, etc., can solve the problems of decreased separation efficiency and effect, slow oil-water separation efficiency, etc., to avoid slow separation efficiency , Improve the liquid flow efficiency, improve the effect of flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

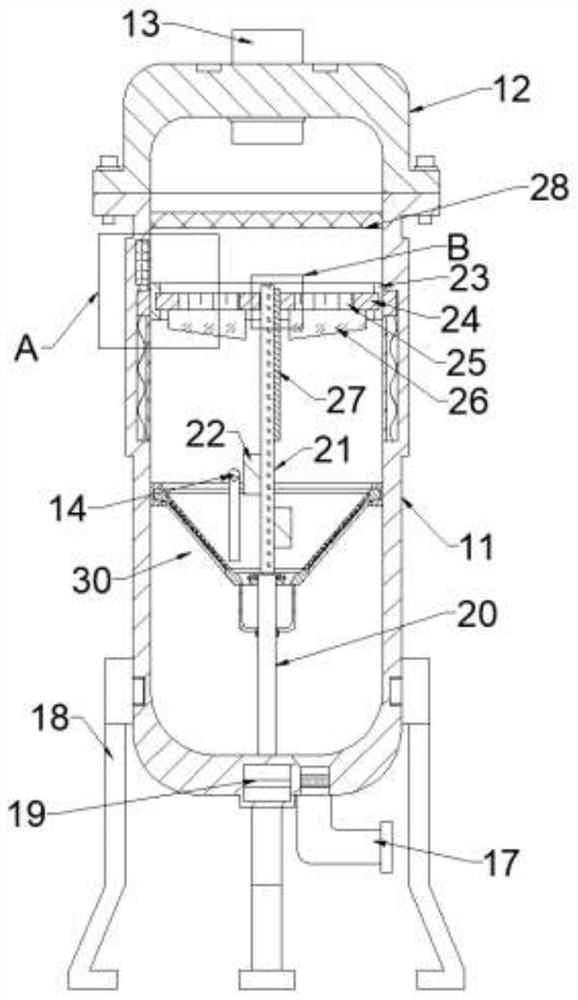

[0029] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are now defined as follows: figure 1 The projection relationship of itself is the same as the up, down, left, right, front, and rear directions.

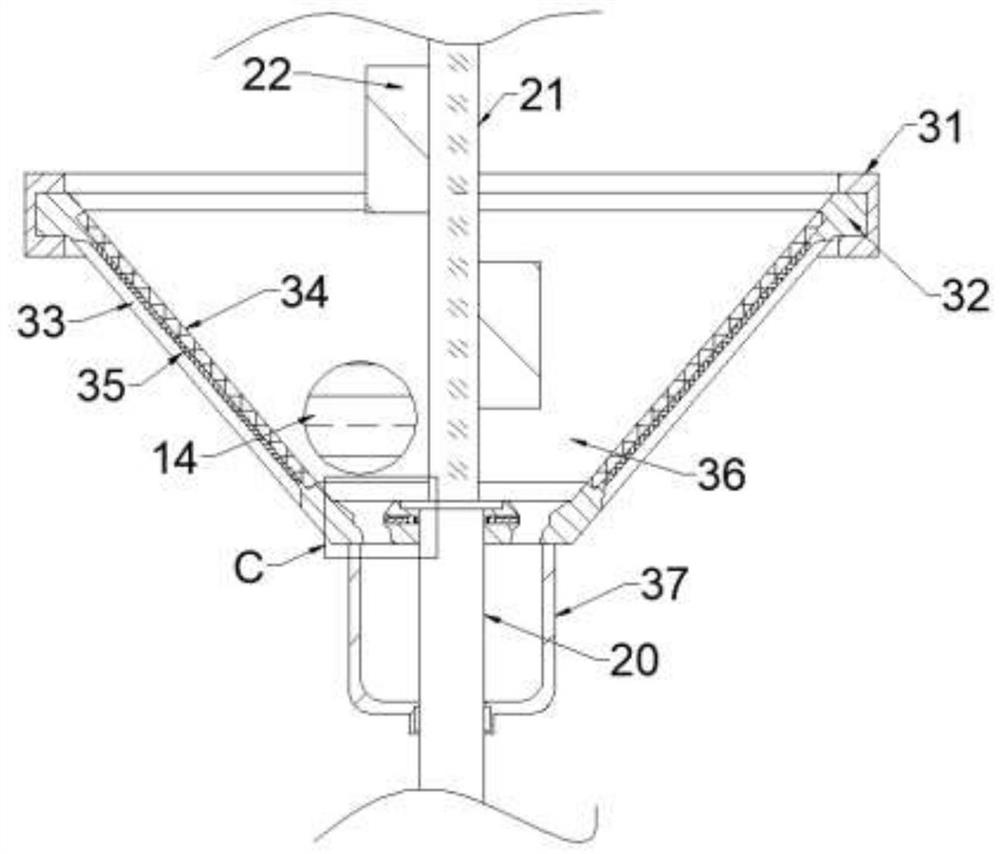

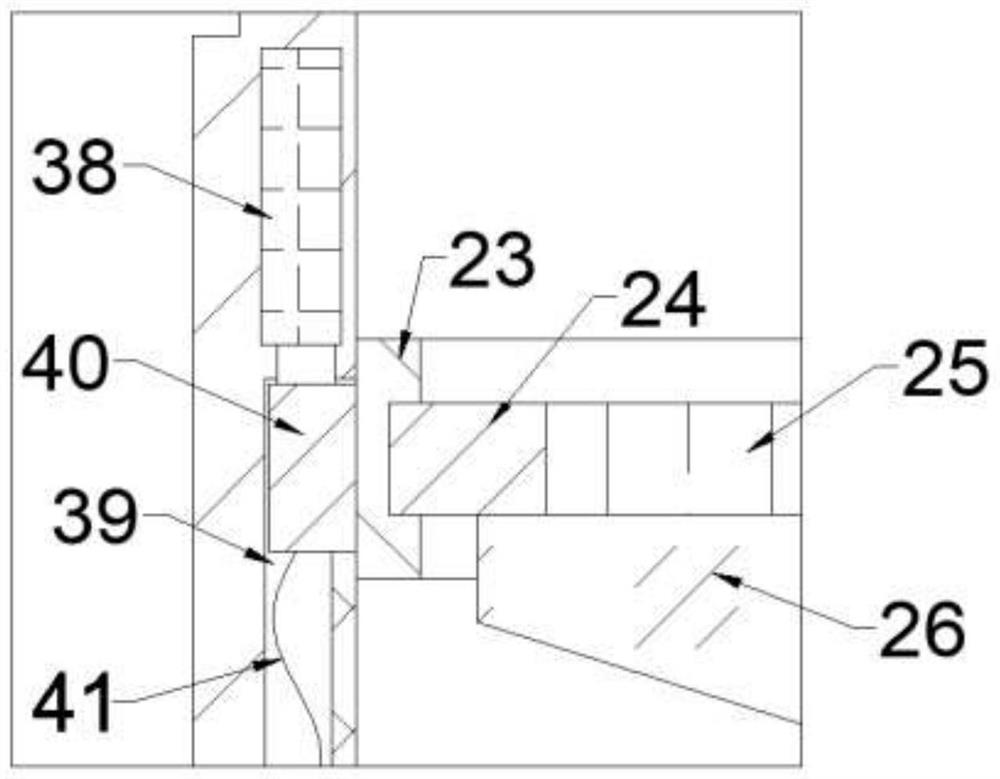

[0030] combined with Figure 1-5 The above-mentioned high-efficiency separation device for petrochemical oil and water includes a separation tank body 11, a filter screen 28 is installed in the separation tank body 11, a mounting ring 23 is slidably installed in the separation tank body 11, and a seal is rotatably installed in the installation ring 23. The pressure plate 24, the sealing pressure plate 24 is provided with a communication valve 25 in an array, the underside of the sealing pressure plate 24 is arranged with a dial 26 in an array, and a conical filter device 30 is installed in the separation tank 11. The conical filter The device 30 includes a fixed ring groove 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com