Regulation and control device and method for improving concentricity of VAD optical fiber preform core cladding

An optical fiber preform and control device technology, which is applied to manufacturing tools, glass manufacturing equipment, glass production, etc., can solve the problems affecting the concentricity quality of the optical fiber preform core package and the inability to guarantee the installation position accuracy of the target rod, so as to improve the core quality. The effect of wrapping concentricity and reducing the degree of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

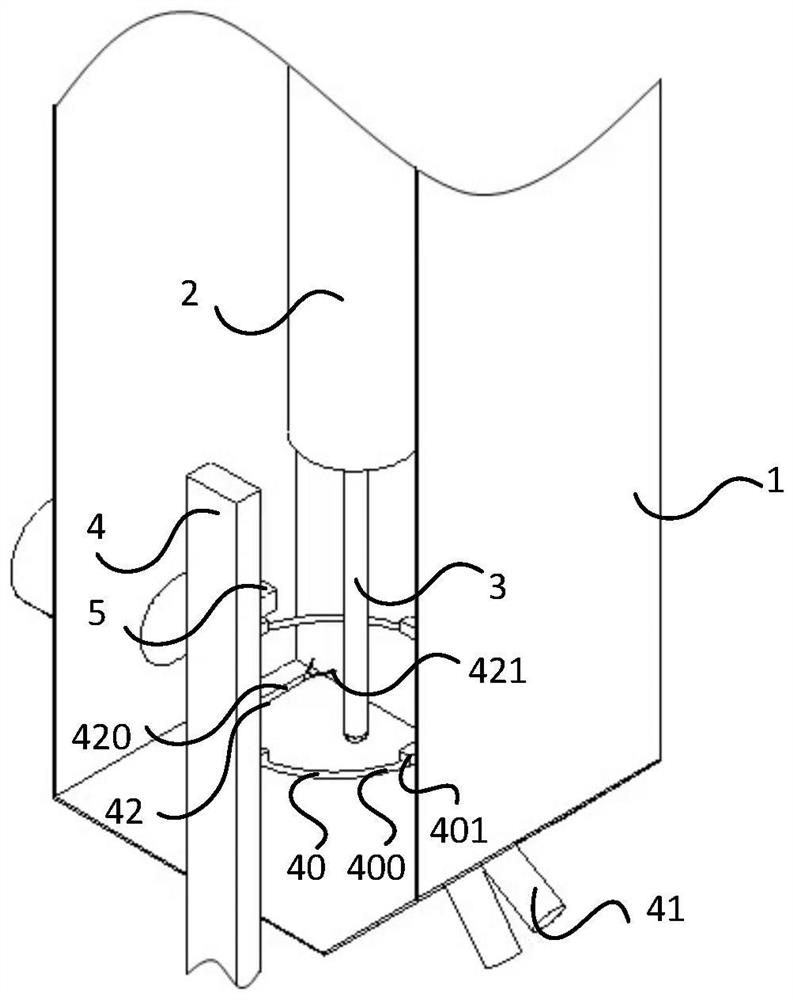

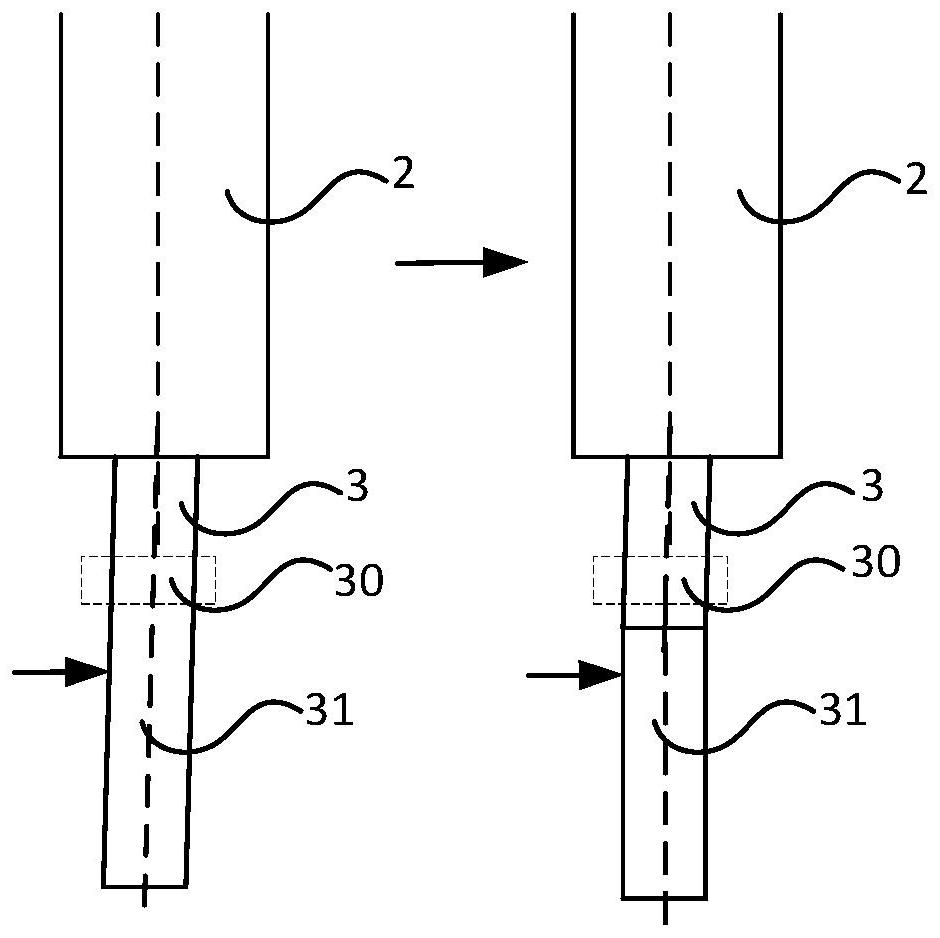

[0040] see figure 1 and figure 2 As shown, Embodiment 1 of the present application provides a control device for improving the concentricity of the VAD optical fiber preform core package, which includes a positioning vehicle 4 and a control mechanism, and the positioning vehicle 4 is an intelligent positioning vehicle, which can automatically Run to the deposition chamber 1 for positioning, and the positioning deviation is ±5mm; the deposition lead rod 2 is set in the deposition chamber 1, and the target rod 3 is suspended under the deposition lead rod 2; The unit 40 is used to detect the first position of the deposition lead rod 2 and the second position of the target rod 3; the push rod 42 is used to push the target segment 31 located below the softening area 30 on the target rod 3 to move; wherein the softening area 30 is controlled by the burner 41 is formed by heating the target rod 3; the control mechanism is connected with the detection unit 40, the torch 41 and the p...

Embodiment 2

[0065] Embodiment 2 of the present application provides a control method for improving the concentricity of the VAD optical fiber preform core package, which includes the following steps:

[0066] S1: Provide a control device for improving the concentricity of the VAD optical fiber preform core package;

[0067] S2: run the positioning vehicle 4 to the deposition chamber 1, so that the push rod 42 faces the deposition lead rod 2 and the target rod 3;

[0068] S3: Detect the first position of the deposition lead 2 and the second position of the target rod 3;

[0069] S4: According to the first position and the second position, determine whether the second position satisfies the preset production conditions;

[0070] S5: When not satisfied, obtain the target displacement of the target rod 3 moving, and control the torch 41 to heat the target rod 3, and control the push rod 42 to push the target segment 31 to move the target displacement.

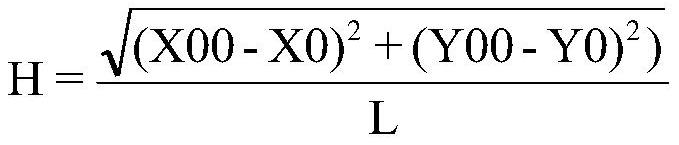

[0071] Specifically: the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com