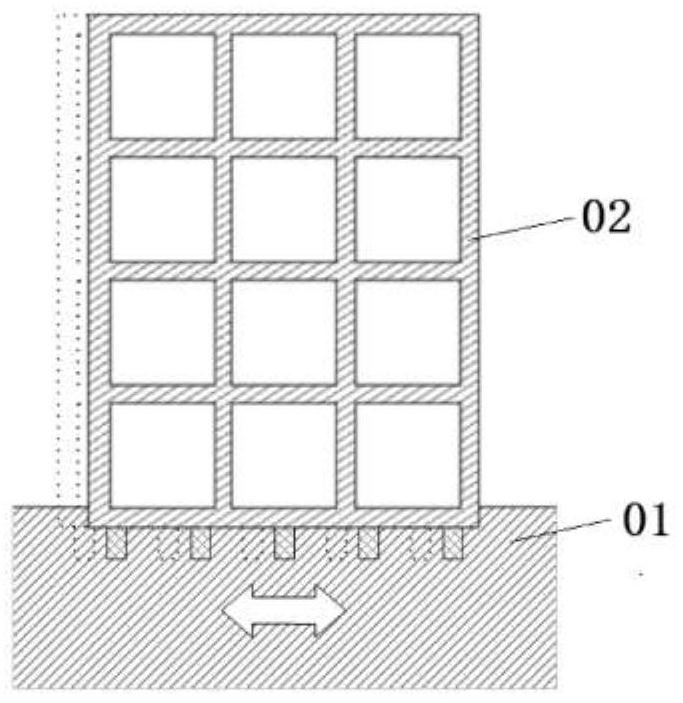

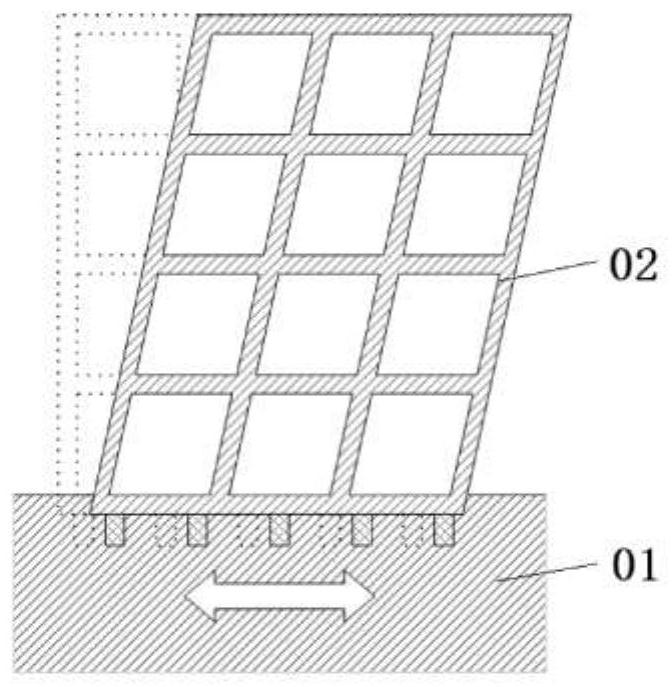

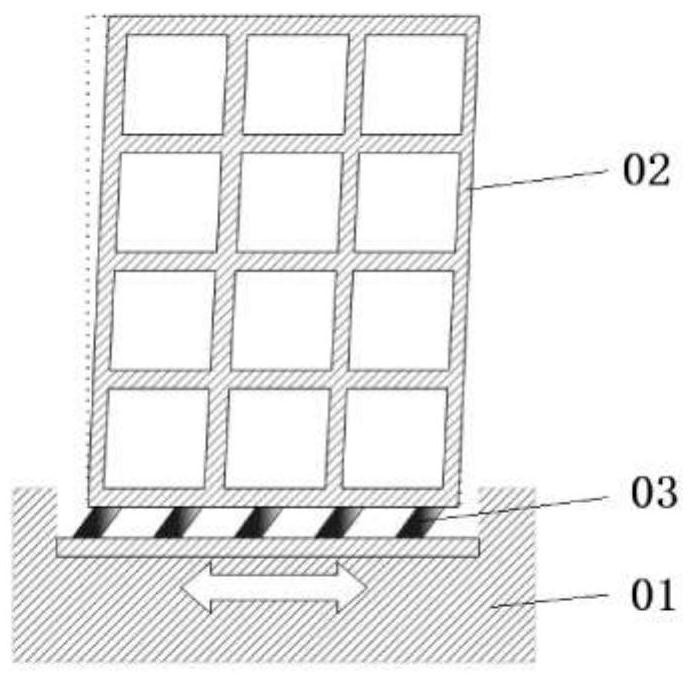

Horizontal omnidirectional earthquake isolation system for building and building system

A seismic isolation system and horizontal technology, applied in the direction of buildings, building types, building components, etc., can solve the problems of bonding failure between rubber sheets and steel plates, compression shear failure, failure of seismic isolation bearings, etc., and achieve design mechanics calculation simplification, The effect of reducing rolling friction resistance and strong vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

[0088] like Figure 1 to Figure 30 As shown, this embodiment provides a horizontal omnidirectional seismic isolation system for buildings, including an upper plate body 1 and a lower plate body 2 arranged in parallel and spaced apart, and spaced between the upper plate body 1 and the lower plate body 2 There is a first retainer 3 (that is, a gap is left between the first retainer 3 and the upper plate body 1 and the lower plate body 2 in the vertical direction), and a plurality of first retainers are arranged in the first retainer 3 The steel balls 31 and the first steel balls 31 are in rolling contact with the lower surface of the upper plate body 1 and the upper surface of the lower plate body 2 . An upper partition wall 11 is protruded down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com