Motion insulator, preparation method thereof and switch comprising motion insulator

An insulator and motion technology, applied in the field of electrical devices, can solve the problems of huge electric power and impact force of the arm, partial discharge failure, etc., and achieve the effect of good toughness, ensuring partial discharge requirements, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are to explain rather than limit the present invention.

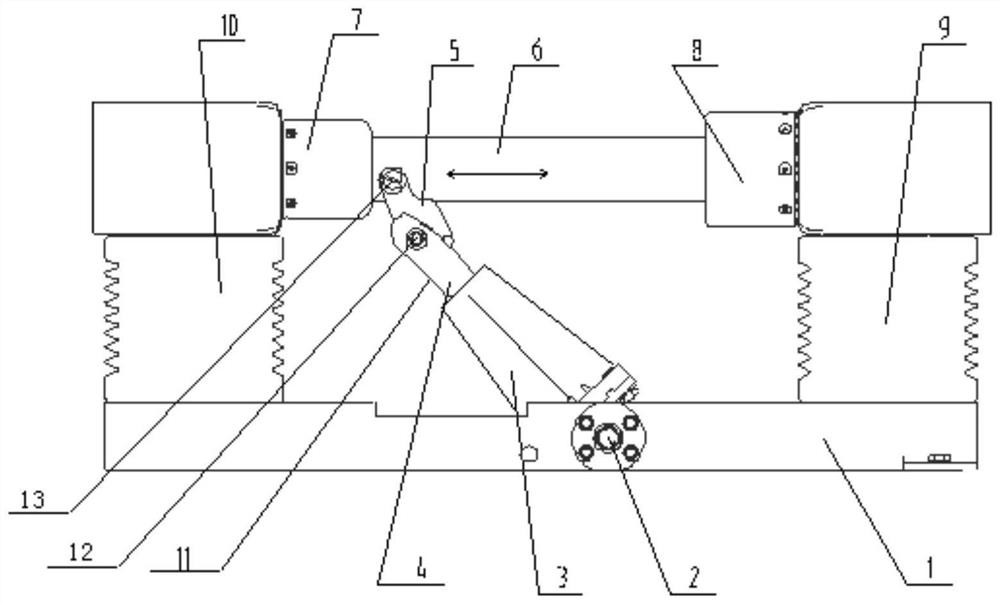

[0040] figure 1 It is a large-capacity switch, including a support 1, a rotating shaft 2, a moving insulator 3, a U-shaped support 4, a connecting plate 5, a moving contact 6, a static contact and a conductor 7, a moving side contact and a conductor 8, and a rotating shaft 2 , the moving insulator 3 and the U-shaped support 4 are assembled into a turning arm 11, and the rotating shaft 2 is installed on the support 1; They are connected by the second pin 12; the high voltage side of the moving insulator 3 is connected to the U-shaped support 4, and the ground potential side of the moving insulator 3 is connected to the rotating shaft 2; a first insulating support 9 is provided on the side of the moving contact 6 , a second insulating support 10 is provided on one side of the static contact, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com