Epitaxial structure and epitaxial growth method thereof, and LED chip

A technology of epitaxial growth and epitaxial structure, applied in the direction of sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc., can solve problems such as insufficient brightness, and achieve the increase of saturation value of light intensity, increase of recombination efficiency, and increase of migration probability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

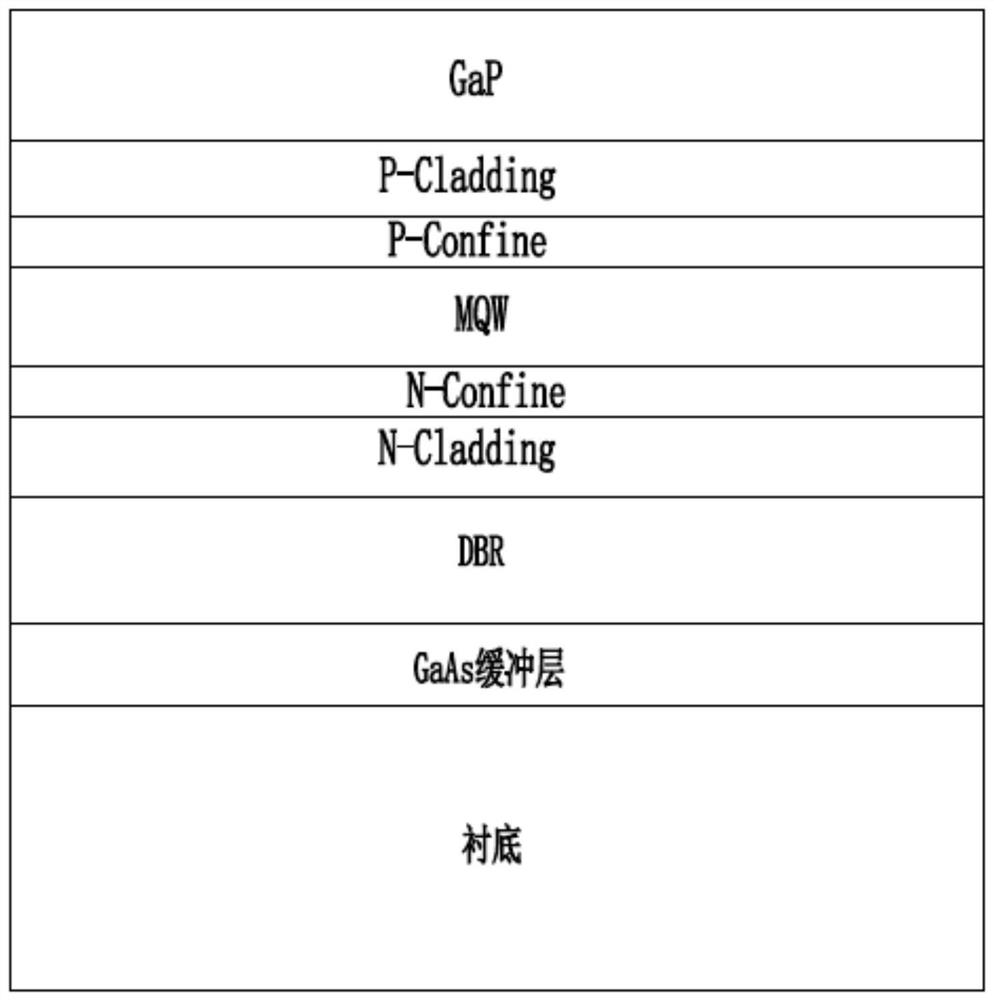

[0032] see figure 1 , shows the epitaxial structure in the first embodiment of the present invention, including a substrate, and a buffer layer, a Bragg reflector (Distributed Bragg Reflection, DBR for short), an N-type cladding layer (N-Cladding) epitaxially grown on the substrate in turn ), N-type confinement layer (N-Confine), multiple quantum well layer (Multiple Quantum Well, referred to as MQW), P-type confinement layer (P-Confine), P-type cladding layer (P-Cladding) and current spreading layer.

[0033] In some preferred cases of this embodiment, the substrate may be a GaAs substrate, the buffer layer may be a GaAs buffer layer, the Bragg mirror includes multiple pairs of alternately grown AlAs layers and GaAs layers, and the N-type cladding layer may be Si-doped AlInP layer, the multiple quantum well layer includes multiple pairs of alternately grown quantum well layers and quantum barrier layers, wherein the materials of the quantum well layer and the quantum barrier ...

Embodiment 2

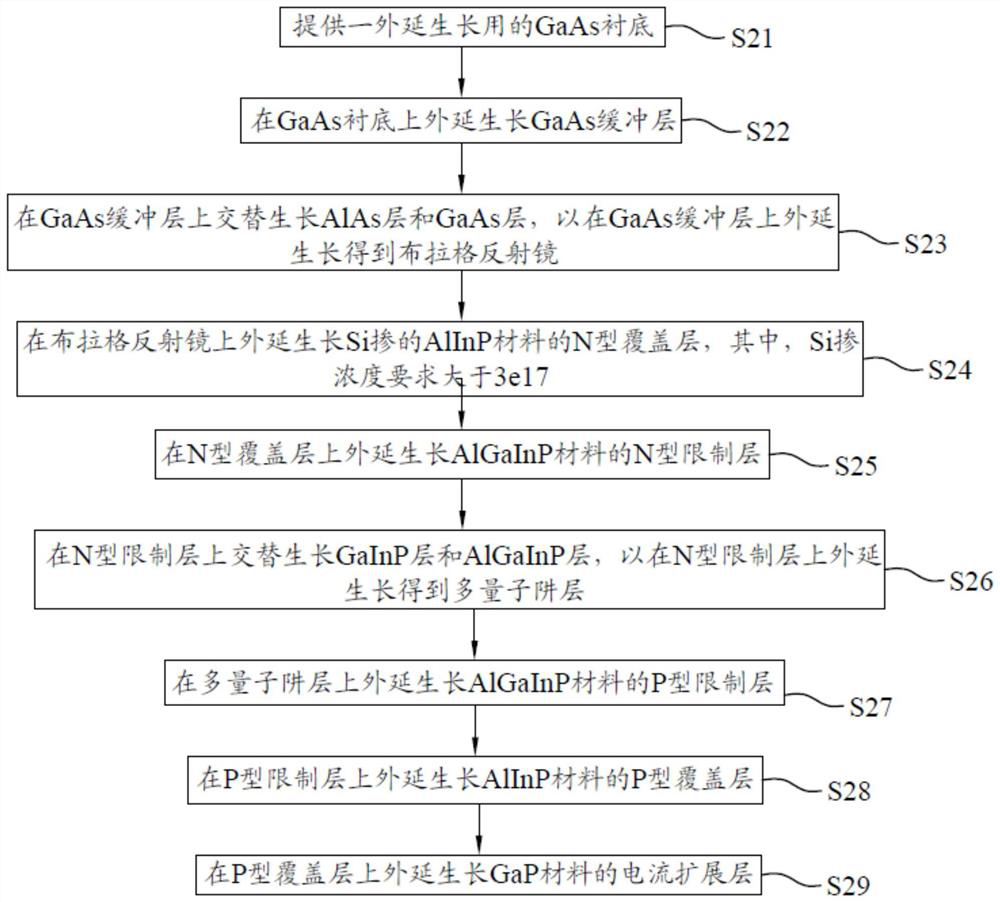

[0037] see figure 2 , shows an epitaxial growth method of an epitaxial structure proposed in the second embodiment of the present invention, which is used to prepare the epitaxial structure in the above-mentioned first embodiment. The method specifically includes steps S21 to S29, wherein:

[0038] Step S21, providing a GaAs substrate for epitaxial growth.

[0039] In step S22, a GaAs buffer layer is epitaxially grown on the GaAs substrate.

[0040] In step S23, AlAs layers and GaAs layers are alternately grown on the GaAs buffer layer to obtain a Bragg mirror by epitaxial growth on the GaAs buffer layer.

[0041] Step S24, epitaxially growing an N-type cladding layer of Si-doped AlInP material on the Bragg mirror, wherein the Si-doped concentration is required to be greater than 3e17 / cm 3 .

[0042] In step S25, an N-type confinement layer of AlGaInP material is epitaxially grown on the N-type cladding layer.

[0043] Step S26, alternately growing GaInP layers and AlGaIn...

Embodiment 3

[0049] The third embodiment of the present invention provides an LED chip, which includes the epitaxial structure in the first embodiment, and the epitaxial structure can be obtained by epitaxial growth by the epitaxial growth method of the epitaxial structure in the second embodiment.

[0050] To sum up, the epitaxial structure, the epitaxial growth method, and the LED chip in the embodiments of the present invention increase the N-layer carrier concentration by increasing the Si doping concentration of the N-type cladding layer, so that under the same conditions, the carrier migration The probability increases, which increases the recombination efficiency of the epitaxial PN junction. In addition, with the increase of the doping concentration of the N-type cladding layer, the logarithm of the barrier and the well is simultaneously increased in the multi-quantum well layer, which increases the limit of carrier overflow and increases the saturation value of the light intensity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com