Wind power plant reactive voltage optimization control method based on data-driven modeling

A voltage optimization, data-driven technology, applied in reactive power compensation, AC network voltage adjustment, electrical components, etc., can solve the problems of long calculation time, difficult calculation of the corresponding relationship between voltage and reactive power, and many types of wind farm equipment. The effect of reducing active power losses and operating costs, avoiding inaccurate power flow calculation results, general and simple mathematical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

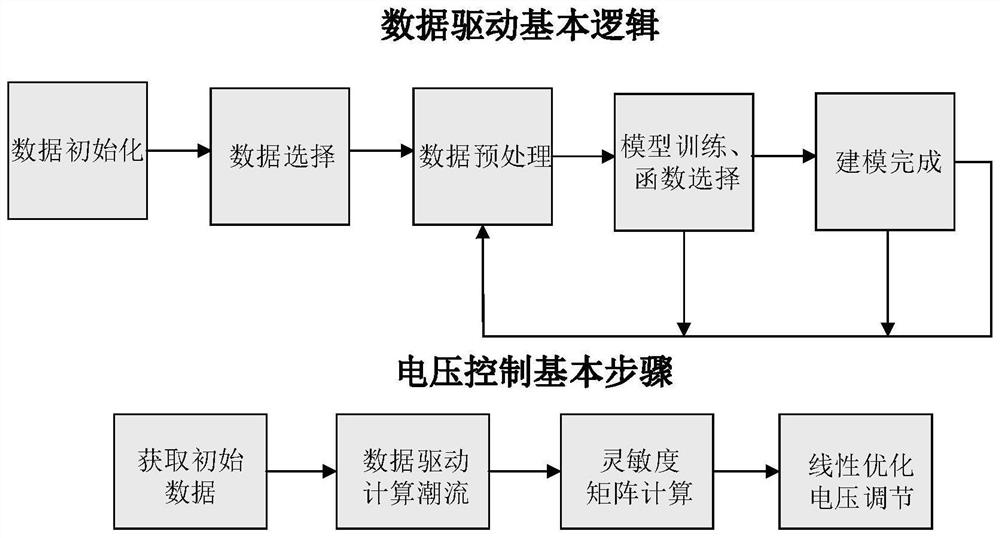

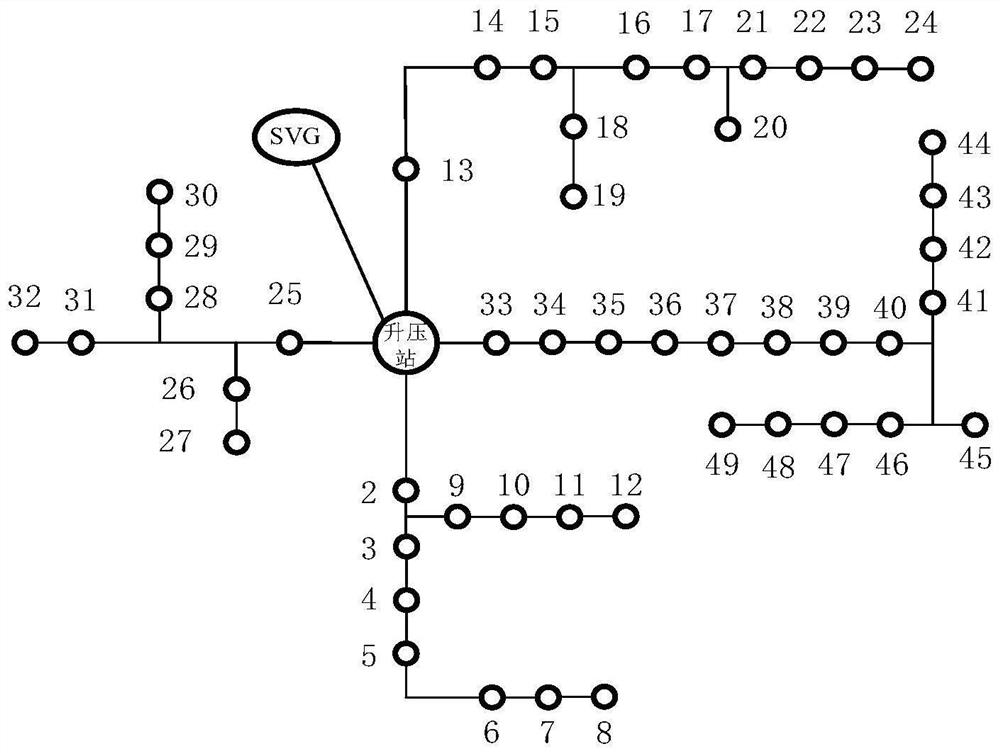

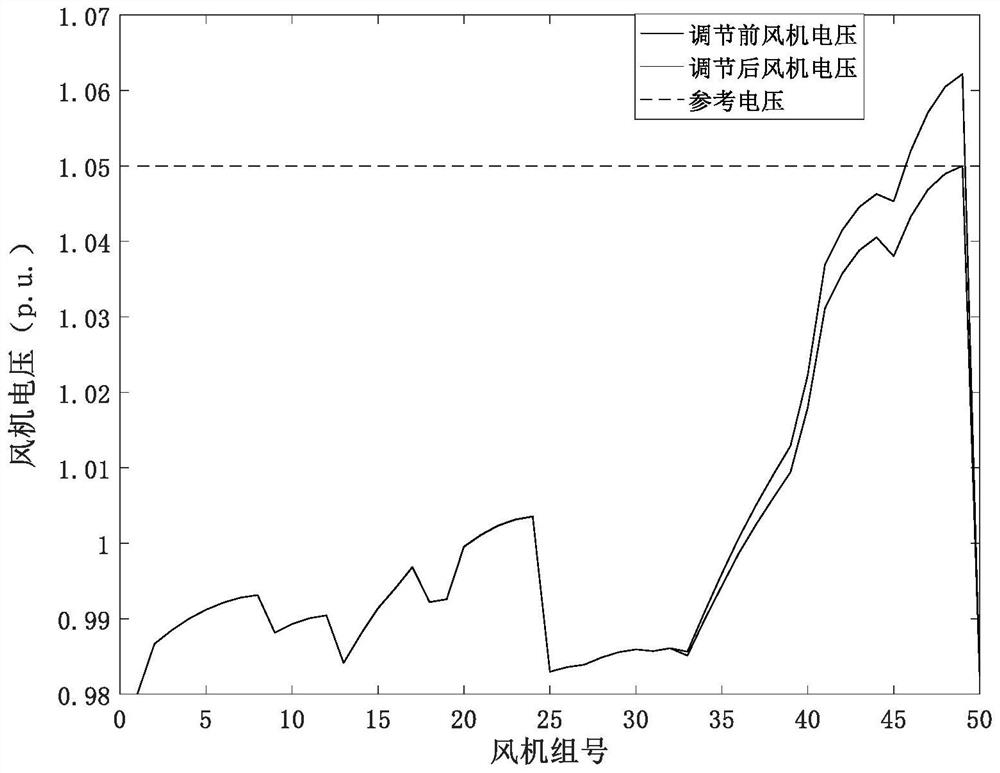

[0051] Quasi-steady-state modeling and reactive power and voltage optimization control method based on data-driven consideration of wind farm topology. The quasi-steady-state modeling of wind power flow is carried out based on the historical data of wind turbines in the wind farm, and the reactive power of wind turbines and the reactive power of static var generators (SVG) are used as control variables, and the control is performed according to the node voltage. The sensitivity relationship of variables, taking the minimum control adjustment amount as the objective function, setting the node voltage linear constraints, and establishing the power system voltage violation optimization model including wind turbines and SVG. This program specifically includes the following steps:

[0052] 1) Suppose the wind farm satisfies the following nonlinear power flow model:

[0053] y=φ(x)

[0054] The basic form of the power flow equation derived by the present invention is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com