Toothbrush bristle planting system and method based on electronic cam control

An electronic cam and toothbrush technology, applied in the control system, vector control system, electronic reversing motor control, etc., can solve the problems of inability to guarantee the execution time of the speed curve, large working noise and mechanical vibration, and speed curve mismatch, etc., to achieve Improvement of working stability, suppression of vibration, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further elaborated below with reference to the accompanying drawings and embodiments.

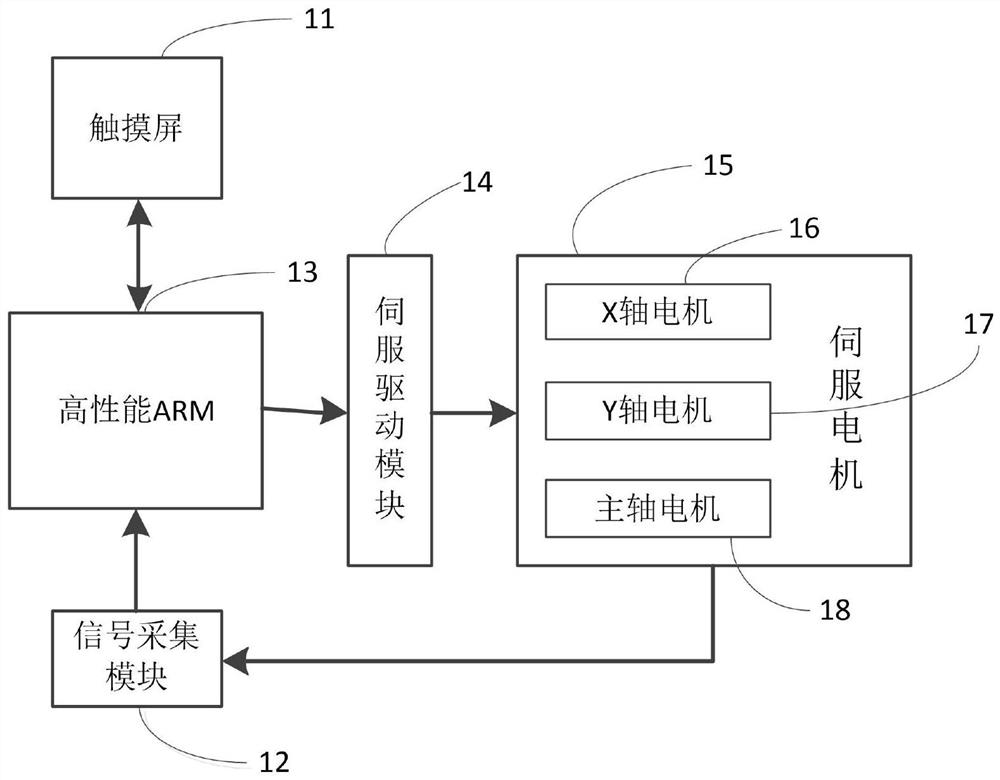

[0041] like figure 1 As shown in the figure, a toothbrush hair implantation system based on electronic cam control, which moves a virtual fourth-axis electronic cam under a three-axis motion platform of a space rectangular coordinate system; the toothbrush hair implantation system includes an XY working platform, a main shaft, a touch screen 11, and a signal acquisition module. 12. The controller 13, the servo drive module 14 and the servo motor group 15. The controller adopts ARM processor. Driven by the servo motor group 15, the XY working platform moves horizontally with two degrees of freedom, and the main shaft moves vertically. The servo motor group 15 includes an X-axis motor 16 , a Y-axis motor 17 and a spindle motor 18 . The XY working platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com