Method for producing binaphthyl carboxylic acid

A manufacturing method and binaphthyl technology, applied in the preparation of carboxylic acid esters/lactones, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as yield or purity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

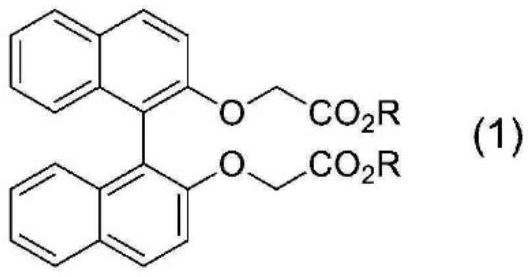

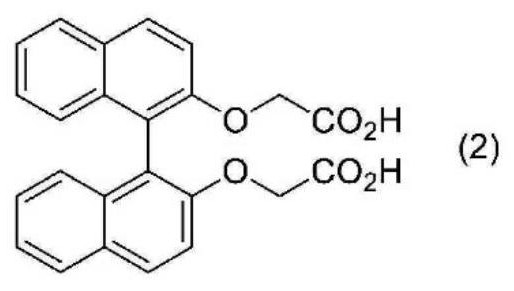

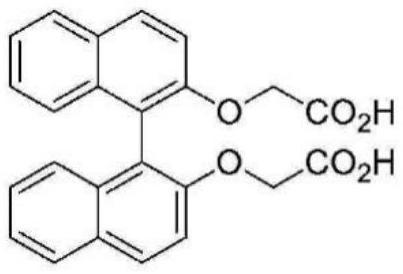

Image

Examples

Embodiment

[0020] Hereinafter, the present invention will be described more specifically with reference to examples, but the present invention is not limited to these examples.

[0021]

[0022]

[0023] The purity of the first-time crystallized crystal of Example 1 was 99.7%, and the content of the monoethyl ester body was 0.2%. On the other hand, the purity of the first crystallization crystal of Comparative Example 1 was 98.3%, the monoethyl ester content was 1.6%, and even in the second crystallization crystal, the purity was 99.2%, and the monoethyl ester content was 99.2%. The ester content was 0.7%. From this result, it was confirmed that the production method of the present invention including the step (ii) is an excellent production method for obtaining high-purity 2,2'-bis(carboxymethoxy)-1,1'-binaphthyl.

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com