Low-pulsation inclined plate precipitation device

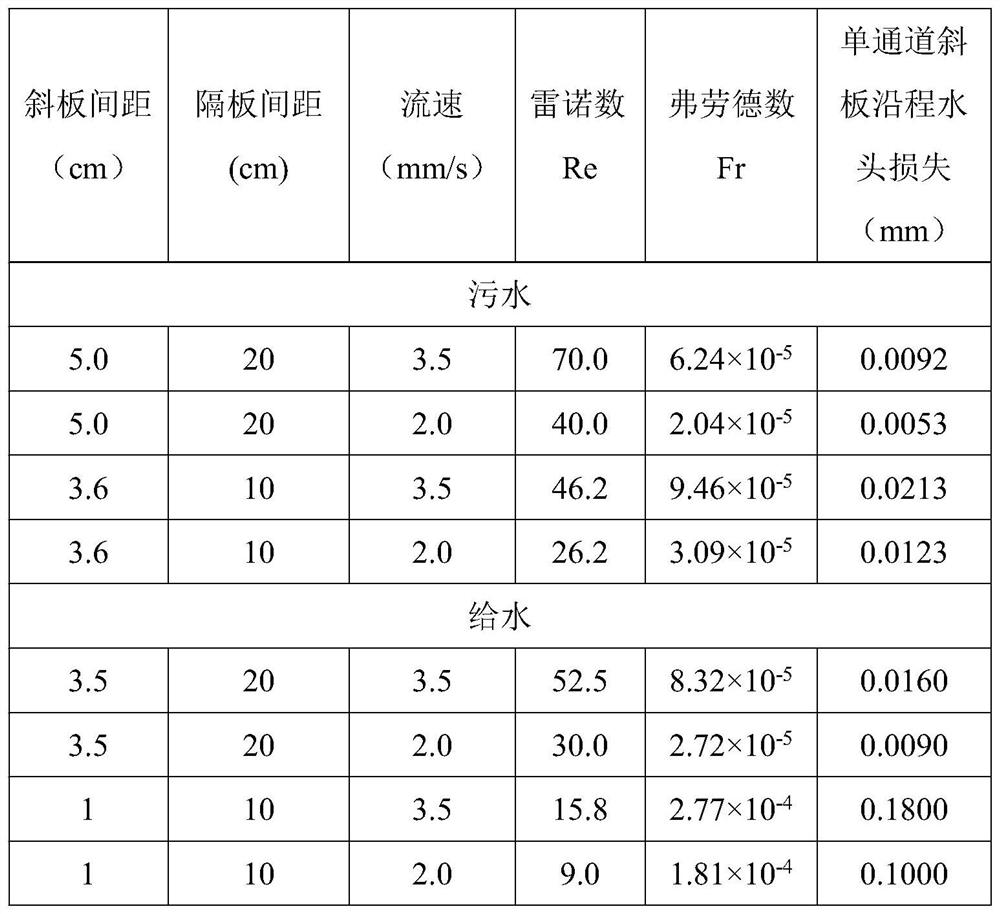

A sloping plate sedimentation and sloping plate technology, applied in the feeding/discharging device of the sedimentation tank, sedimentation separation, flocculation/sedimentation water/sewage treatment, etc. The resistance increases, the sedimentation efficiency is improved, and the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

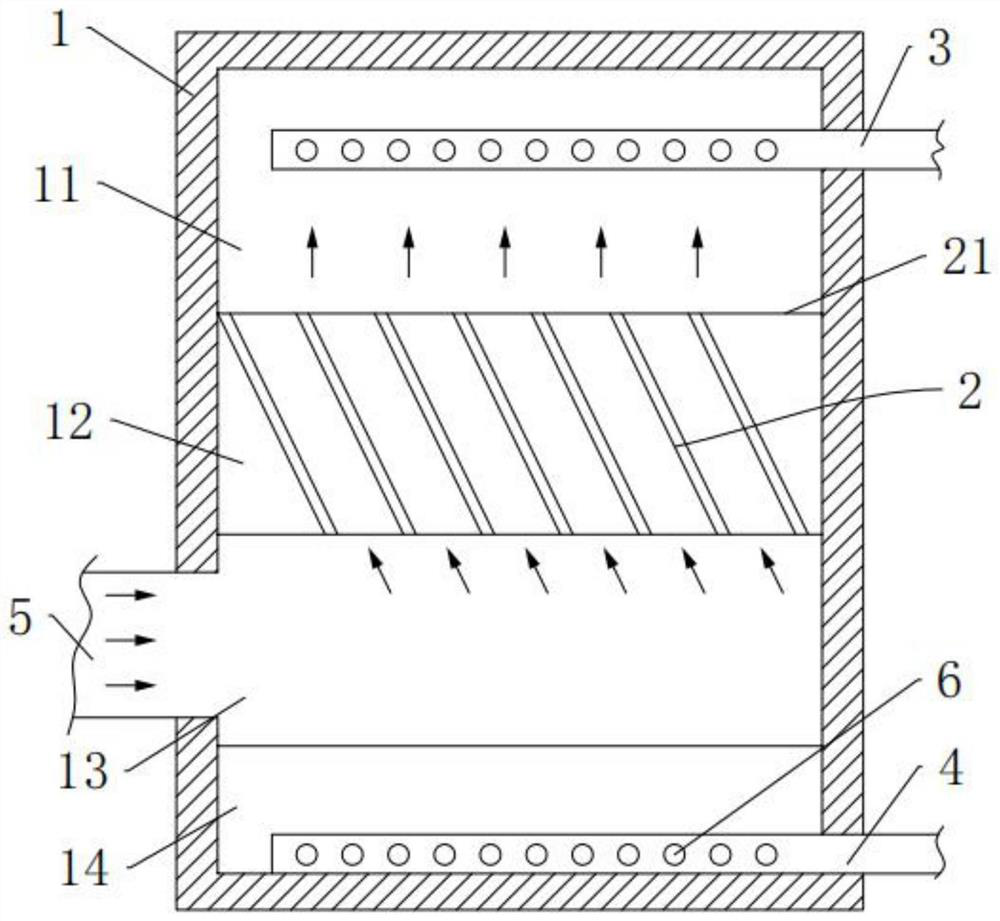

[0022] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

[0023] like Figure 1-3 As shown, the embodiment provides a low-pulsation inclined plate precipitation device, including a sedimentation tank 1, a inclined plate group 2, a perforated water collection pipe 3 and a perforated mud discharge pipe 4. The sedimentation tank 1 is sequentially opened with clean water from top to bottom. Area 11, inclined pipe area 12, water distribution area 13 and mud accumulation area 14, perforated water collecting pipe 3 is horizontally arranged in clean water area 11, inclined plate group 2 is fixed in inclined pipe area 12, and water inlet 5 is opened on one side of water distribution area 13 , a perforated mud discharge pipe 4 is laterally arranged in the mud accumulation area 14;

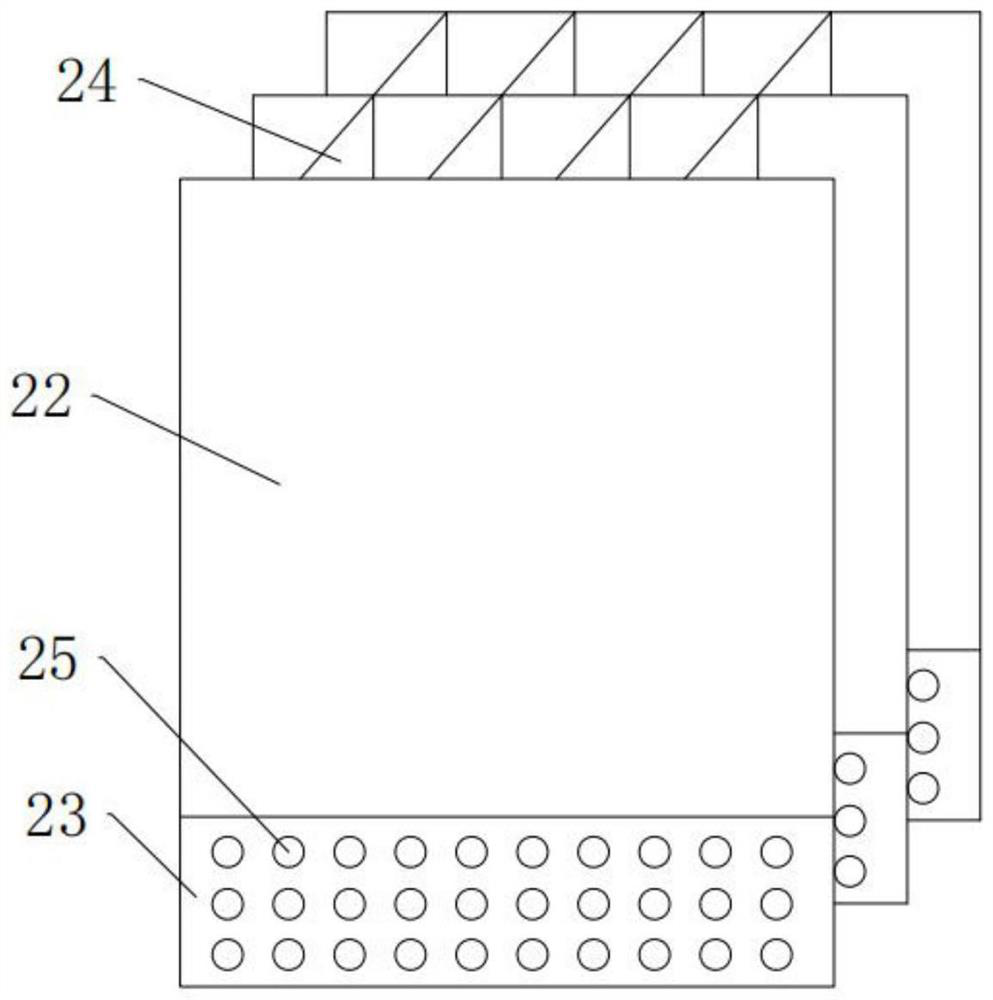

[0024] The inclined plate group 2 includes a support rod 21, a inclined plate 22, a perforated plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com