Rapid carton packaging device

A fast, carton-based technology, applied in the field of carton manufacturing, can solve the problems of tapes and ropes, environmental pollution, inability to reuse, high work intensity, etc., to achieve the effects of avoiding environmental pollution, reducing processing costs, and reducing work intensity

Inactive Publication Date: 2022-06-21

杭州南峰包装材料有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The existing packing of cartons is generally done manually. This method has high work intensity and low efficiency, and most of the existing packing methods are packed with tape and ropes. As a result, when the cartons are in use, the tapes and ropes are directly discarded and cannot be reused. Use, the cost of use is high, and waste tapes and ropes are likely to cause environmental pollution. In order to solve the above problems, we have improved this and proposed a carton quick packing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

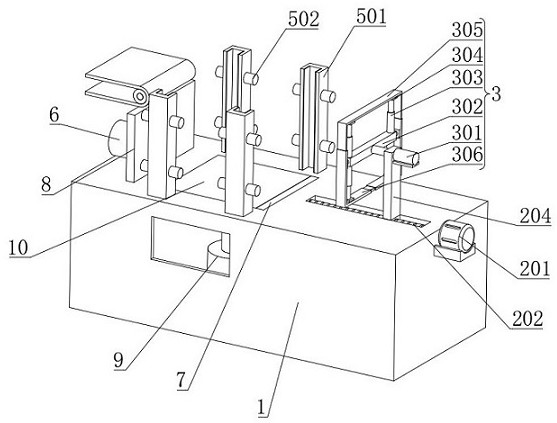

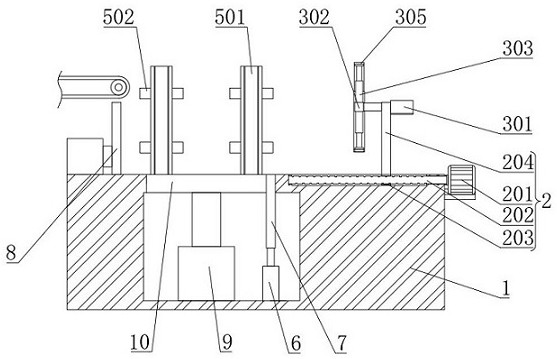

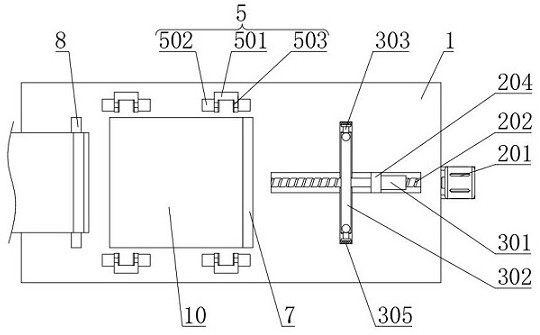

The invention discloses a rapid carton packaging device, and relates to the technical field of carton manufacturing. The device comprises a workbench, a moving mechanism is arranged on the right side of the workbench, the moving mechanism comprises a moving rod, a transferring mechanism is arranged at the upper end of the moving rod, and by arranging the transferring mechanism, the moving mechanism and a limiting mechanism, when a servo motor in the transferring mechanism works, a threaded rod can be driven to rotate; according to the carton packaging device, the moving block, the moving rod and the transferring mechanism are driven to move leftwards, then the packaging support is driven to move to the packaging position through a first electric telescopic rod on the transferring mechanism, then the packaging support is clamped and fixed through a third electric telescopic rod and a clamping plate of the limiting mechanism, and then follow-up packaging work of cartons is facilitated; therefore, the manual feeding step is reduced, the working intensity is reduced, the working efficiency is improved, the packaging support can be recycled after the carton is used, the machining cost is reduced, and environmental pollution is avoided.

Description

technical field [0001] The invention relates to the technical field of carton manufacturing, in particular to a carton quick packing device. Background technique [0002] Cartons can be used to package food, beverages, household appliances, medicine, daily necessities, cosmetics, electromechanical products, etc. The weight of the carton is light, and the weight of a wooden board of the same thickness is about three times that of the cardboard; the cost of the carton is low, and its raw material is base paper, which can be used for wood pulp , made of straw pulp, and can be recycled and reused conveniently; the carton is easy to process, because the paper is flat, it is convenient for printing; it is convenient for storage and transportation, the carton can be folded, which is convenient for storage and transportation. [0003] The existing packing of cartons is generally done manually. This method has high work intensity and low efficiency, and most of the existing packing m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65B35/50

CPCB65B35/50

Inventor 沈冬生

Owner 杭州南峰包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com