Fluid controller

A technology of fluid controller and flow channel, which is applied in the direction of diaphragm valve, valve device, valve housing structure, etc., can solve the problems of liquid leakage, diaphragm diaphragm pressure piece damage, elastic body plastic deformation, etc., and achieve the purpose of inhibiting rubber elastic body damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

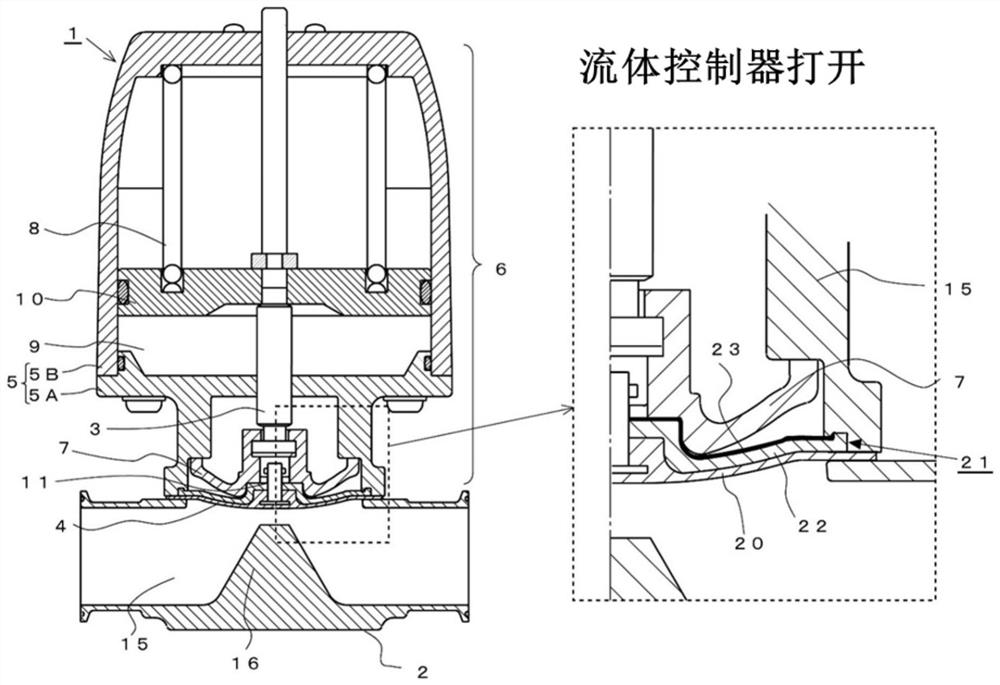

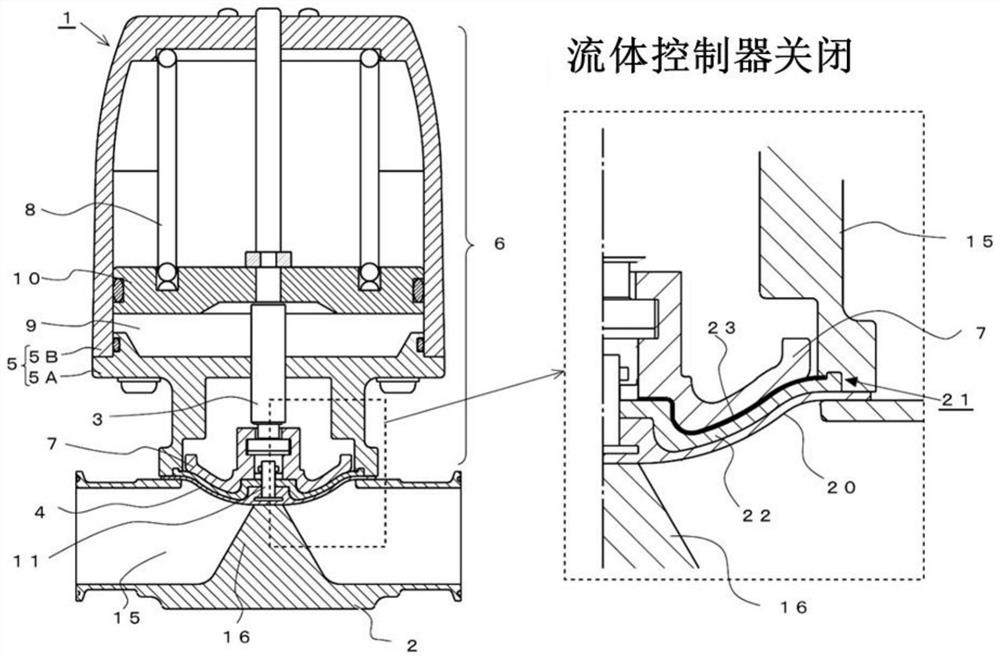

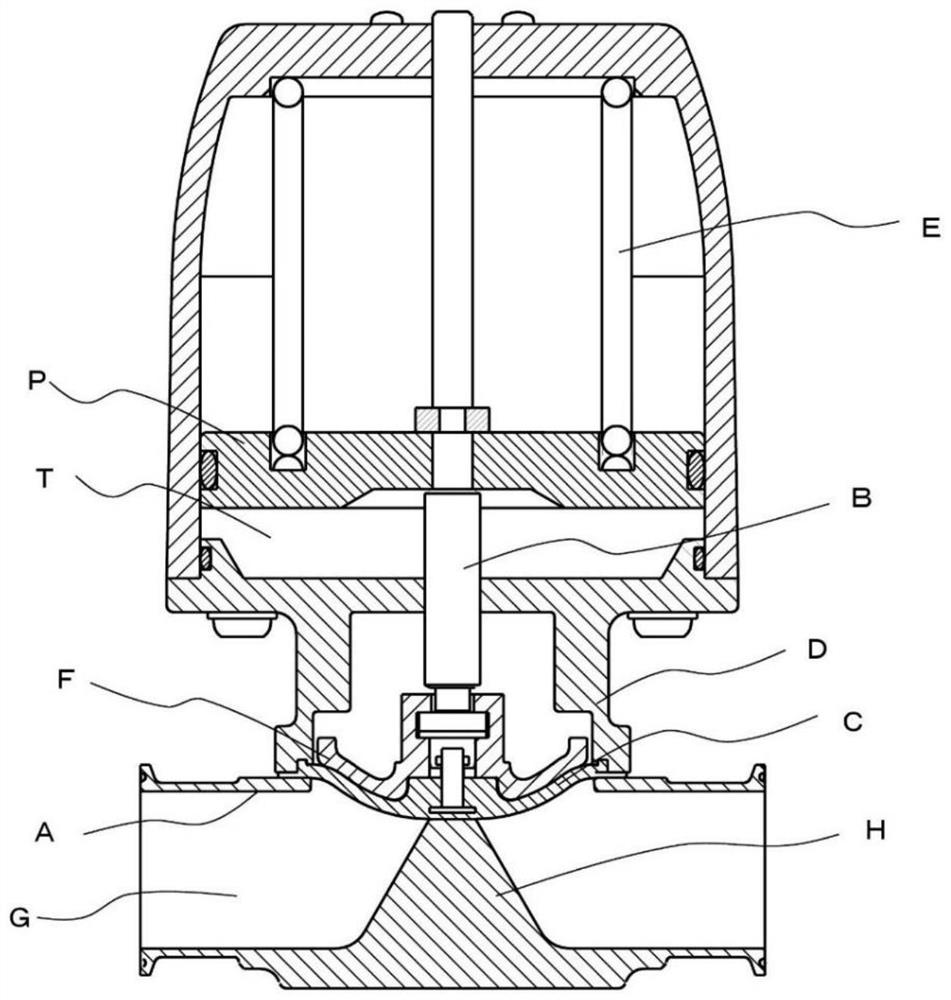

[0038] Embodiments of the fluid controller of the present invention will be described in further detail below with reference to the accompanying drawings.

[0039] Figures 1 to 2 The fluid controller of the present invention is described. The fluid controller (1) of the present invention comprises: a valve box (2) having a fluid flow channel (15), a diaphragm (4) arranged in the valve box (2) and opening and closing the flow channel (15), and a valve The cavity (5) of the peripheral part of the diaphragm (4) and the operating mechanism (6) are sandwiched between the boxes (2). The cavity (5) comprises: a first cavity (5A) with a diaphragm (4) sandwiched between it and the valve box (2); a second cavity (5B) on which the piston (10) slides on its inner surface; The two are held together by screws or other fastening means.

[0040] In the valve box (2), a flow channel (15) and a weir (16) are provided for the flow of the fluid. The flow path side of the diaphragm (4) is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com