Non-meat-source characteristic meat flavor yeast extract and preparation method thereof

A technology of yeast extract and meat flavor, applied in the field of food additives, can solve the problems of inability to meet the requirements of clean label attributes, and achieve the effect of reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

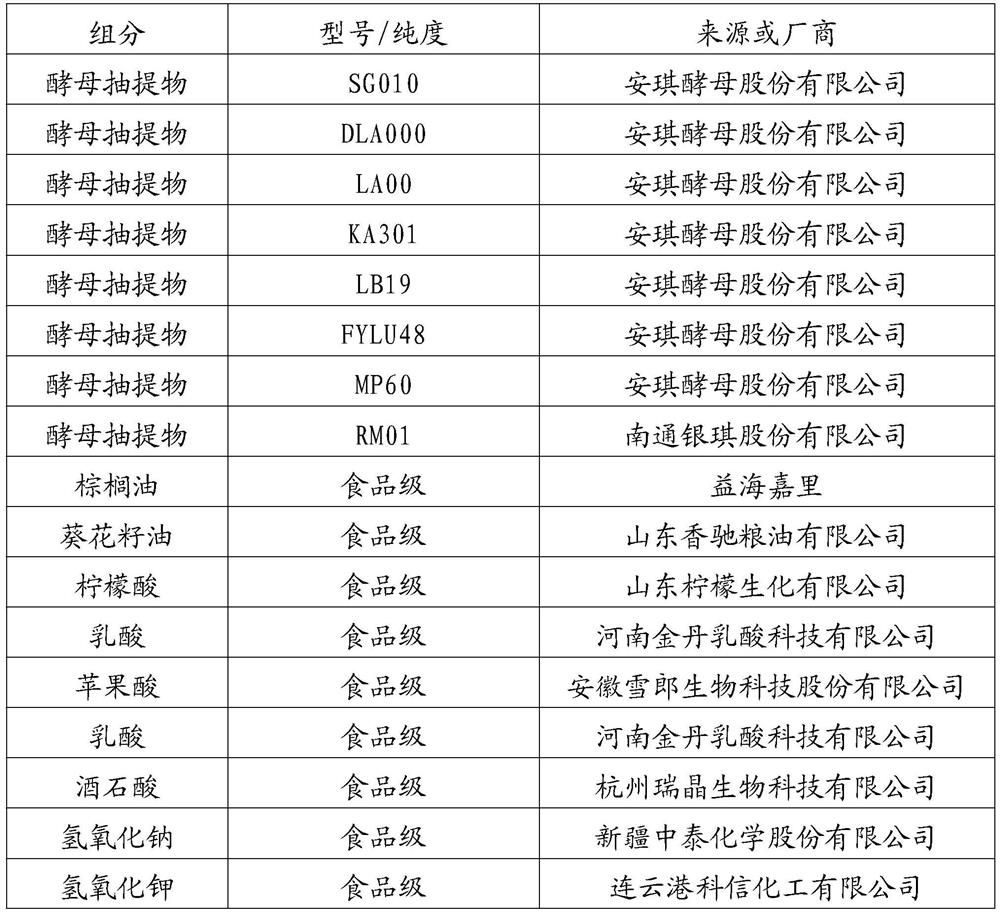

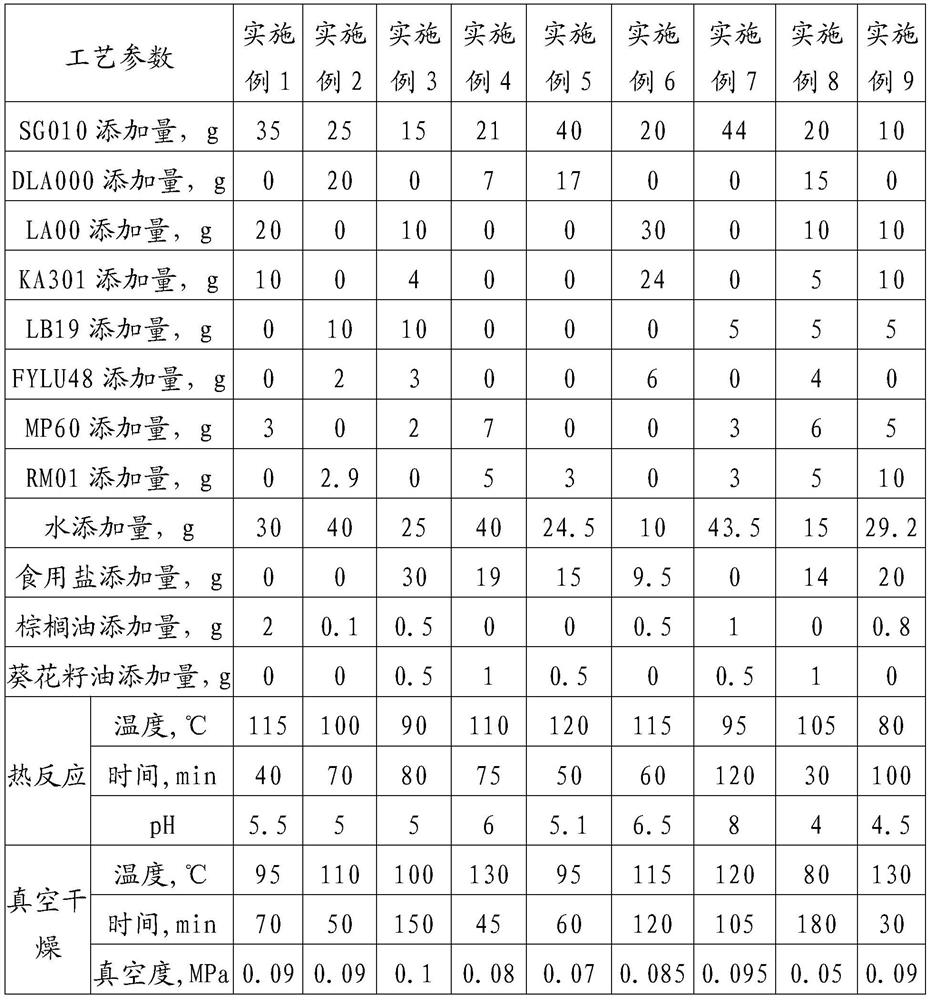

[0017] Specifically, a method for preparing a non-meat-derived meat-flavored yeast extract includes the following steps: (1) adding the weighed yeast extract and water into a batching tank and mixing to obtain a mixture, and then adding The mixture is put into a thermal reaction tank; (2) a pH regulator is added to the thermal reaction tank, the pH is adjusted at 4.0-8.0, the temperature is raised to 80-120° C., and the reaction is stirred for 30-120 minutes to obtain a thermal reactant; (3) Add vegetable oil to the above-mentioned thermal reactant, and add edible salt according to taste requirements, stir and mix evenly to obtain the material to be dried; (4) place the material to be dried obtained in step (3) in a vacuum drying device to dry, and the dried The material is pulverized by a pulverizer and sieved to obtain powder products with different fineness.

[0018] Preferably, the yeast extract, water, edible salt and vegetable oil are as follows in parts by weight: 40-80...

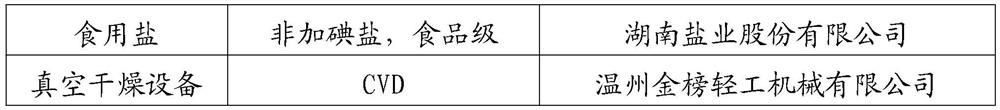

Embodiment 1

[0034] The yeast extract 35gSG010, 10gKA301, 20gLA00, 3gMP60, and 30g water were weighed as shown in Table 2, Example 1, and added to the batching tank for mixing to obtain a mixture. Then, the mixture was put into a hot reaction tank, adjusted to pH=5.5 with citric acid, and thermally reacted at 115° C. for 40 minutes to obtain a thermal reaction product. Then, 2g palm oil was added to the above thermal reaction product to obtain the material to be dried. Finally, the above material to be dried was placed in a vacuum drying equipment, dried for 70 minutes at 95°C and a vacuum degree of 0.09Mpa and pulverized to obtain powder non-meat. Source Characteristics Meat Flavored Yeast Extract 1.

[0035] The non-meat-derived characteristic meat-flavored yeast extract 1 prepared in this Example 1 was golden yellow, and was evaluated by sensory assessors, and the product had a mellow and full mouthfeel, strong chicken flavor, and characteristic chicken flavor.

Embodiment 2

[0037] According to the same steps as Example 1, and operating according to the process conditions listed in Example 2 in Table 2, wherein the pH adjusting agent is malic acid, powdery non-meat-derived characteristic meat-flavored yeast extract 2 is obtained.

[0038] The non-meat-derived characteristic meat-flavored yeast extract 2 prepared in Example 2 was brown, and was evaluated by sensory assessors, and the product had good roasted aroma, pure and full mouthfeel, strong beef flavor, and characteristic beef flavor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com