Preparation of sodium carbonate peroxide and its dry granular products

A technology of sodium peroxycarbonate, sodium carbonate, applied in directions such as peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, organic peroxy/inorganic per compound compositions, etc., It can solve the problems of substandard products, low recovery rate, low reagent conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

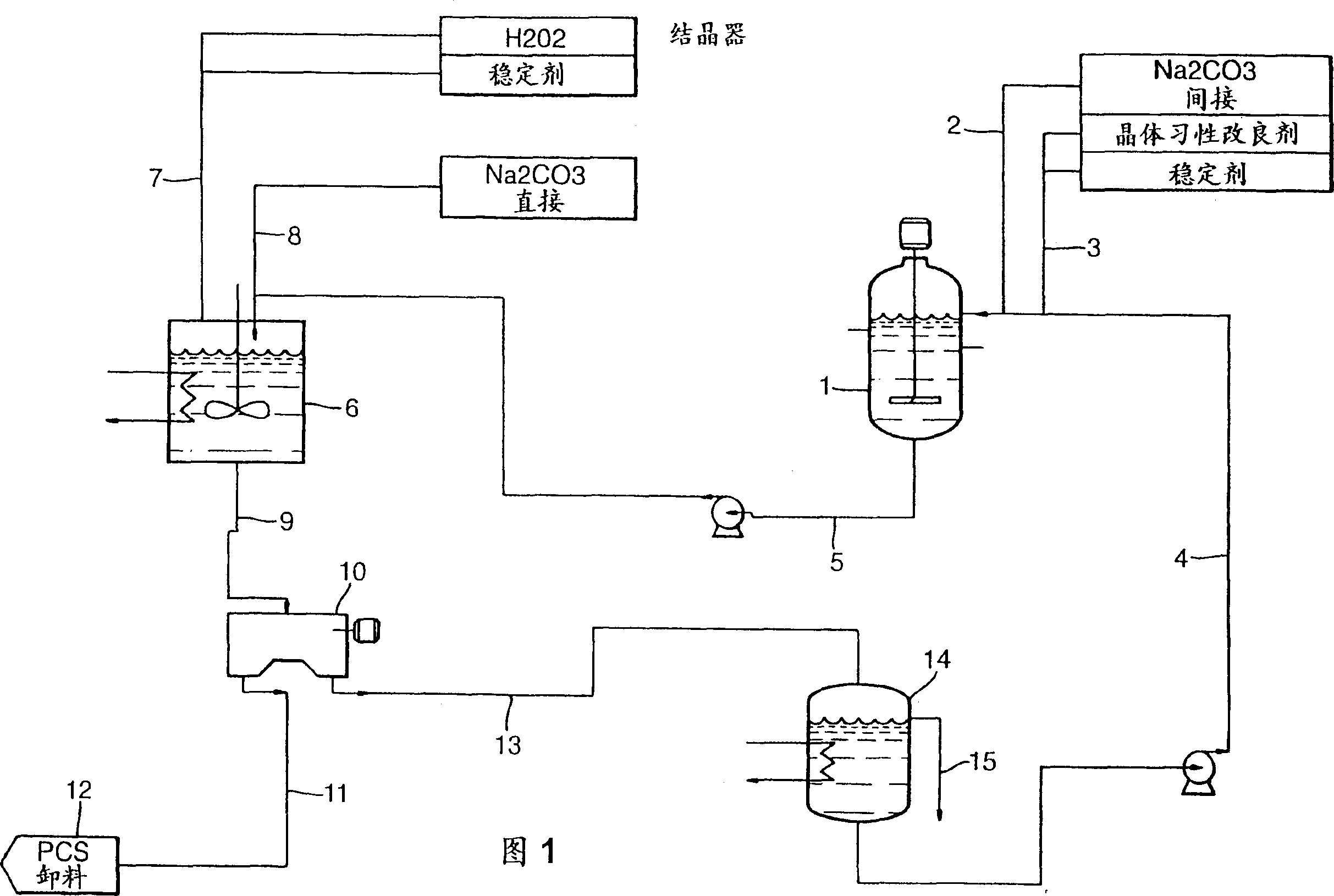

[0099] In this example, a set of equipment in Fig. 1 is used to continuously produce PCS without adding any salting-out agent. 60% of the soda ash was added per cycle via the dissolution tank at 25°C, resulting in a solution of 87% saturated solution concentration, and 40% of the soda ash was added by direct addition of solids to the reactor. Leaving the dissolving tank mother liquor peroxide content is 30g / L. The molar ratio of sodium carbonate to hydrogen peroxide in the crystallizer is kept at 1-1.1:1. After drying of sodium percarbonate, the 7-day aging thermal radiation is 1 μW / g for 16 hours, and the average particle size is 680 microns (when using the laser particle size analyzer according to the formula (D 90 -D 10 ) / D 50 When measuring, the span (span) is 1.0, where D is the diameter expressed in microns). The product had a moisture absorption of 14 g / kg, a bulk density of 990 g / kg and an oxygen content of 14.7%.

example 2

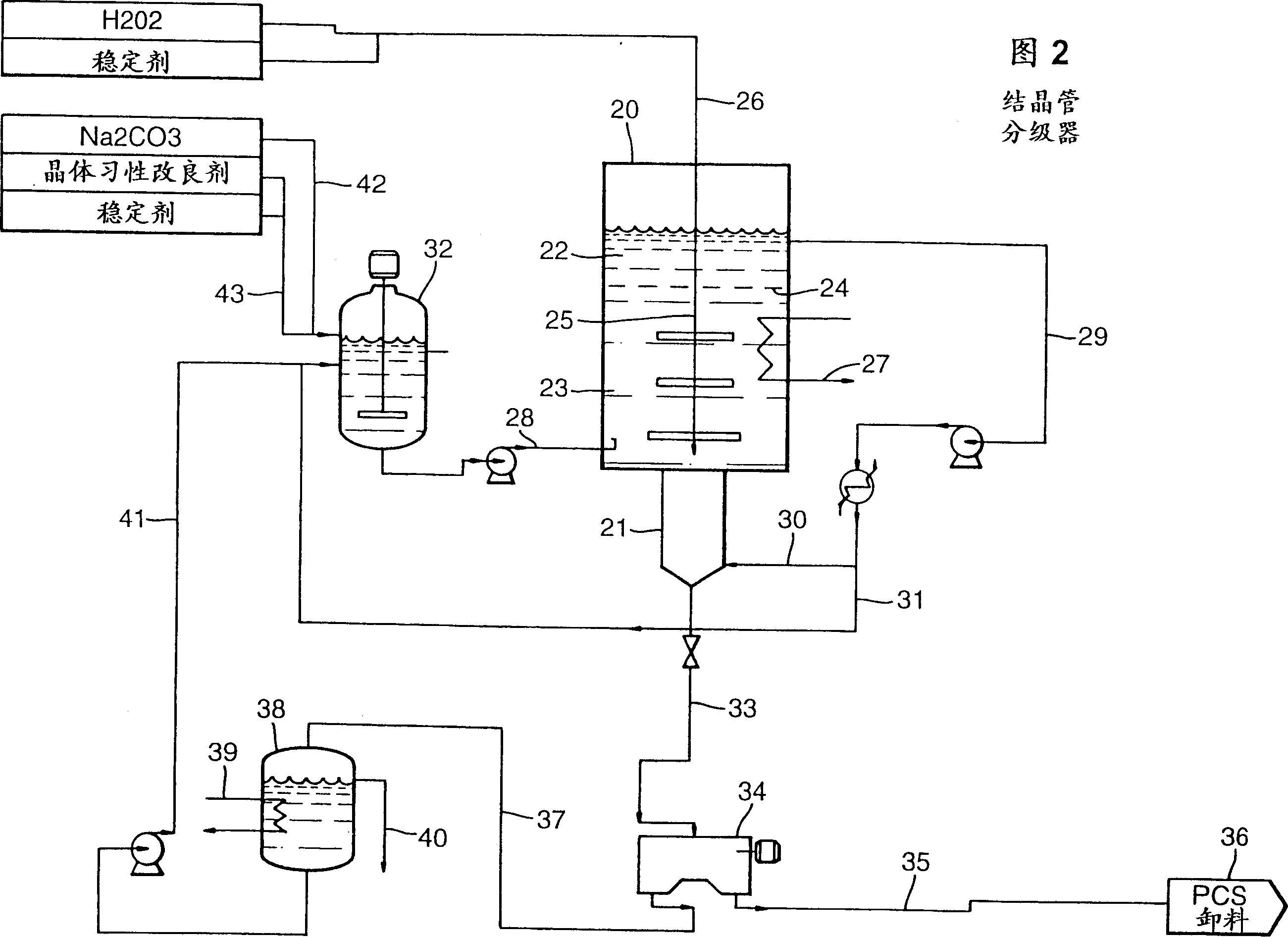

[0101] In this example, a set of equipment in Fig. 2 is used to continuously produce PCS without adding any salting-out agent. The dissolution tank is operated at 45°C, and the soda ash is dissolved in the circulating mother liquor to reach a concentration of 76% saturated solution. The mother liquor leaving the dissolving tank contains 8g / L hydrogen peroxide. The molar ratio of sodium carbonate to hydrogen peroxide in the crystallizer is kept at 1-1.1:1.

[0102] The resulting product had an average particle size of 650 microns (span 0.9), a 7-day aging heat radiation of 2 µW / g, a moisture absorption of 1.5 g / kg and an available oxygen of 14.9%. Compared with Example 1, it can be seen that the method loses more hydrogen peroxide in the process of Example 2 return, while the product retains the good heat radiation and hygroscopic properties of Example 1.

example 3-5

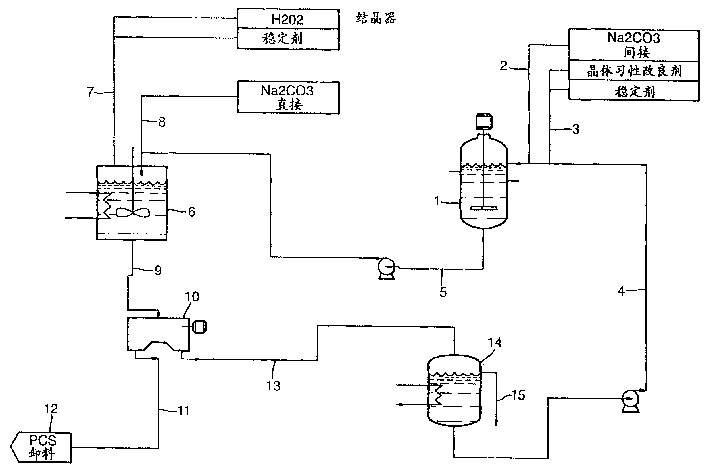

[0104] These examples, according to Fig. 1 a set of equipment is operated, and 100% soda ash that will add directly joins reactor. The hydrogen peroxide to sodium carbonate mol ratio in the reactor, the dissolution tank temperature and product characteristics are summarized in Table 1 below.

[0105] instance number

[0106] As can be seen from Table 1, products with both low thermal radiation (LKB) and high available oxygen can be obtained, and it is observed that the average particle size increases with H 2 o 2 The correlation tends to increase with increasing molar ratios of soda ash, demonstrating that, for at least some applications, the optimum molar ratio is from about 0.8 to about 0.85:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com