Large-arc taper spherical milling cutter

A technology of spherical milling cutter and large arc, which is applied in the direction of milling cutter, milling machine equipment, metal processing equipment, etc., can solve the problems of long overhang length of the tool, short cutting life of the tool, and shortening of the cutting life, so as to improve the cutting efficiency , Tool life extension, overhang length reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

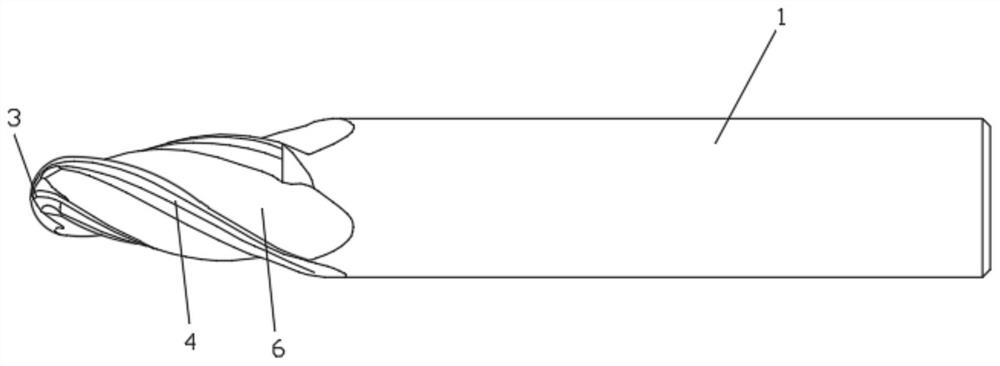

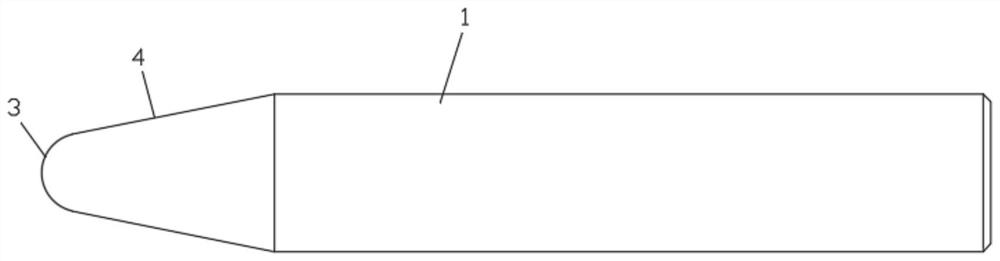

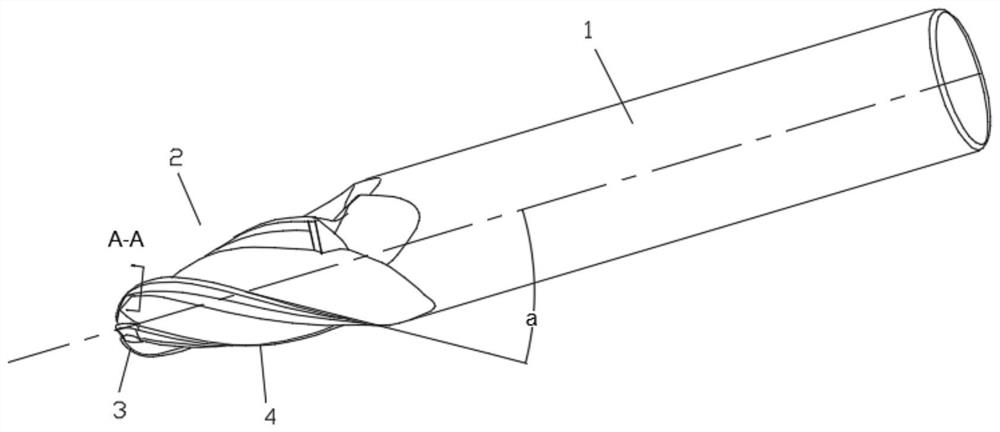

[0021] like Figure 1 to Figure 6 As shown, the present invention provides a large-arc taper spherical milling cutter, comprising an integral shank 1 and a cutting edge 2, the cutting edge 2 includes a ball-end cutting edge 3 and a large-circle-arc side edge 4, and the adjacent ball-end cutting edge There is a chip flute 5 between 3, and a chip flute 6 is provided between the adjacent large arc side edges 4. The chip flute 5 and the chip flute 6 communicate with each other. The front end is tangent to the ball-end blade 3, the rear end is tangent to the handle 1, and the radius of the large arc side blade 4 is R800mm-R1000mm.

[0022] On the basis of the above scheme, the helix angle a of the large arc side edge 4 is 30°-45°, preferably 42°-45°. The large helix angle design can ensure a large depth of cut and make cutting more brisk.

[0023] Wherein, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com