Shot blasting machine with shot circulating system

A circulatory system and shot blasting machine technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of shot blasting waste, blockage of sieve holes, affecting shot blasting and sieving, and reduce production. cost and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

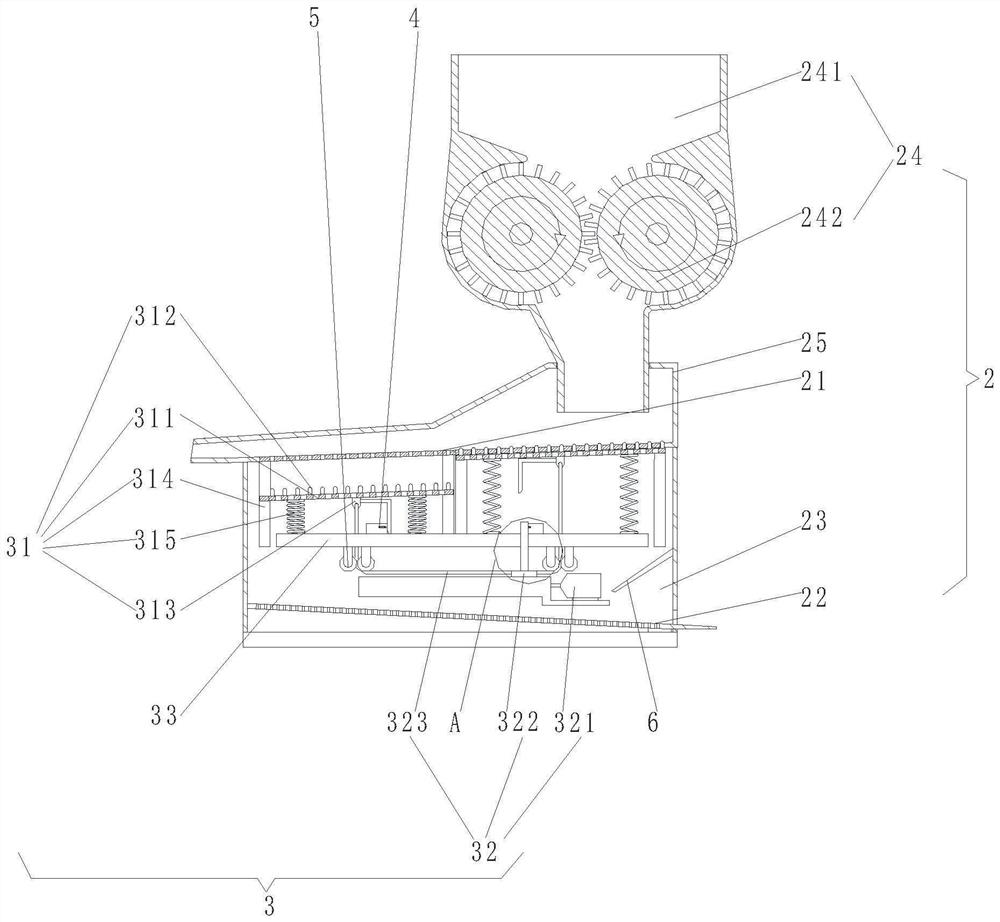

[0029] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the shot blasting machine with the shot blasting system described in this embodiment includes a shot blasting box 1 and an impurity removal device 2 arranged on one side of the shot blasting box 1. The interior of the shot blasting box 1 is provided with a recovery channel and a storage The shot box, the recovery channel recovers the shot blasting and sends it to the impurity removal device 2, the shot storage box is used to collect the shot blasting after the impurity removal, and the impurity removal device 2 includes the first screen 21, the second screen 22 and the protection box 23, the protective box 23 is arranged at the bottom of the first screen 21, and the second screen 22 is arranged inside the protective box 23;

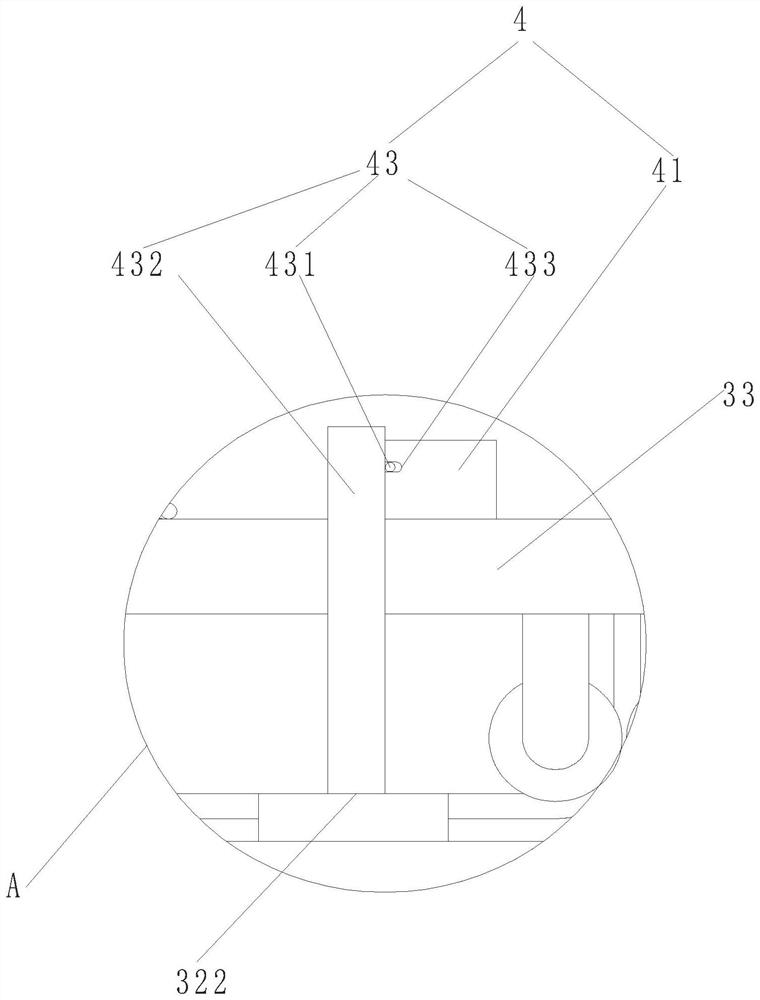

[0030] A dredging device 3 is provided below the first screen 21, and the dredging device 3 includes a dredging piece 31 and a driving piece 32, a stopper 33 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com