Washable DLP 3D printing dental cast resin

A resin and dental mold technology, applied in the field of 3D printing, can solve problems such as process risks, pollution, waste liquid, etc., and achieve the effects of improving efficiency, solving risks and pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

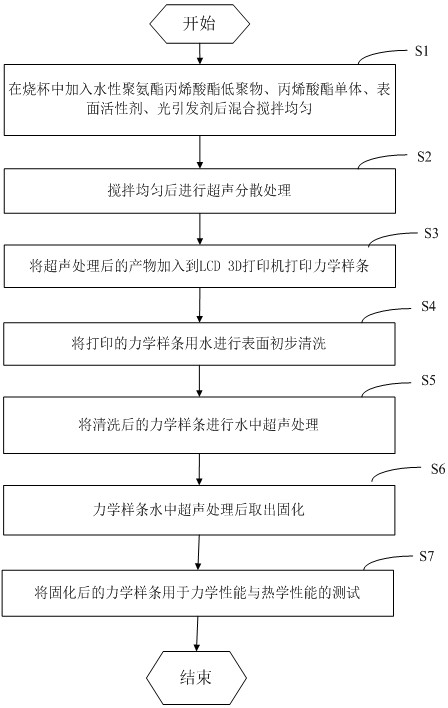

[0037] A water-washable DLP3D printing dental mold resin formulation, the preparation method of which specifically includes the following steps:

[0038] Step 1: Add water-based urethane acrylate oligomer, acrylate monomer, surfactant and photoinitiator into the beaker, mix and stir evenly;

[0039] Step 2: ultrasonically disperse for 5 minutes after stirring evenly;

[0040] Step 3: Add the ultrasonically processed product to the LCD 3D printer to print the mechanical spline;

[0041] Step 4: Preliminarily clean the surface of the printed mechanical spline with water;

[0042] Step 5: ultrasonically treat the cleaned mechanical splines in water for 5 minutes;

[0043] Step 6: The mechanical spline is taken out and cured after ultrasonic treatment in water;

[0044] Step 7: The cured mechanical splines are used for the testing of mechanical properties and thermal properties.

Embodiment 1

[0046] The formula of the washable DLP 3D printing dental mold resin is:

[0047] Solmer SWA8038: 50g

[0048] Polyethylene glycol diacrylate (average molecular weight 700): 20g

[0049] Acryloylmorpholine: 30g

[0050] TPO: 3g

[0051] PEG3000: 2g

[0052] Its preparation method is:

[0053] Step 1: Add 50g of Solmer SWA8038, 20g of polyethylene glycol diacrylate (average molecular weight 700), 30g of acryloyl morpholine, 3g of TPO and 2g of PEG3000 into the beaker, then mix and stir well;

[0054] Step 2: ultrasonically disperse for 5 minutes after stirring evenly;

[0055] Step 3: Add the ultrasonically processed product to the LCD 3D printer to print the mechanical spline;

[0056] Step 4: Preliminarily clean the surface of the printed mechanical spline with water;

[0057] Step 5: ultrasonically treat the cleaned mechanical splines in water for 5 minutes;

[0058] Step 6: The mechanical spline is taken out and cured after ultrasonic treatment in water;

[0059] S...

Embodiment 2

[0061] The formula of the washable DLP 3D printing dental mold resin is:

[0062] Solmer SWA8041: 30g

[0063] Methoxy polyethylene glycol monoacrylate (average molecular weight 480): 20g

[0064] Acryloylmorpholine: 50g

[0065] TPO: 1g

[0066] PEG20000: 0.2g

[0067] Its preparation method is:

[0068]Step 1: Add 30g of Solmer SWA8041, 20g of methoxy polyethylene glycol monoacrylate (average molecular weight 480), 50g of acryloyl morpholine, 1g of TPO and 0.2g of PEG20000 into a beaker, and mix and stir well;

[0069] Step 2: ultrasonically disperse for 5 minutes after stirring evenly;

[0070] Step 3: Add the ultrasonically processed product to the LCD 3D printer to print the mechanical spline;

[0071] Step 4: Preliminarily clean the surface of the printed mechanical spline with water;

[0072] Step 5: ultrasonically treat the cleaned mechanical splines in water for 5 minutes;

[0073] Step 6: The mechanical spline is taken out and cured after ultrasonic treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com