Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification and preparation method of Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy

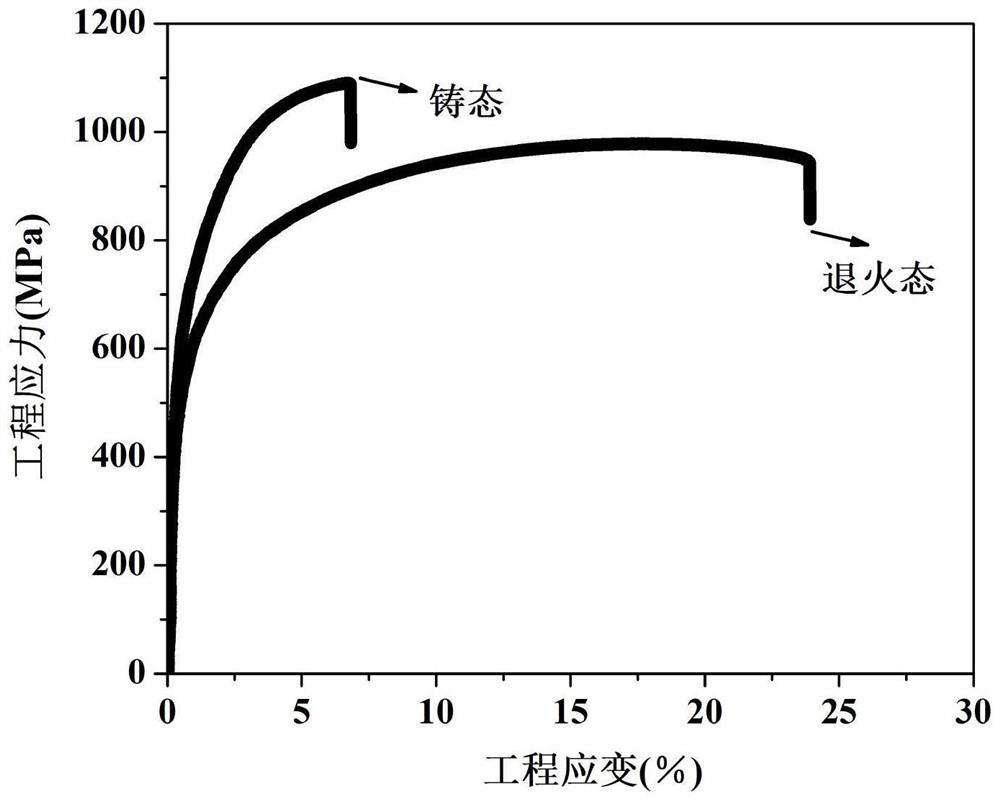

A co-cr-fe-ni-v-b, high-entropy alloy technology, applied in the field of high-entropy alloys, can solve the problems of rare reports on the non-metallization design of eutectic high-entropy alloys, and achieve significant thermal modification characteristics and less casting The effect of improving defect and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

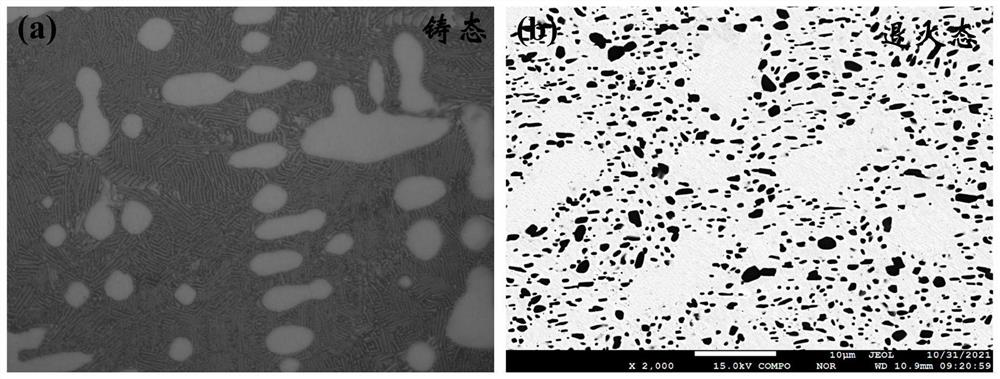

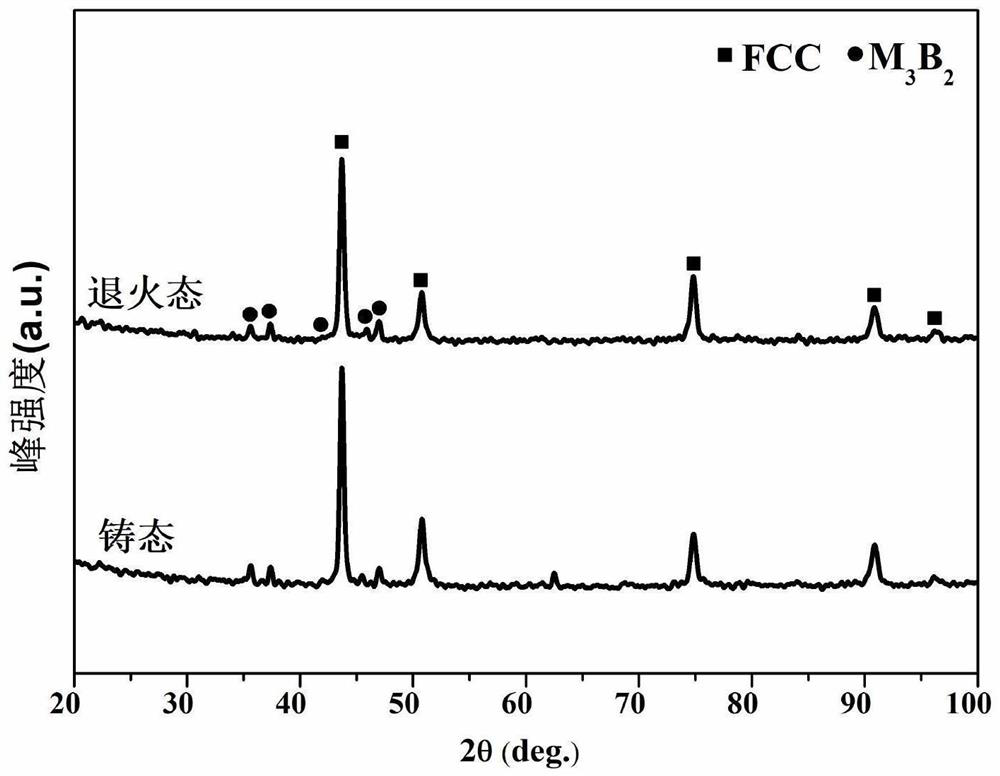

[0028] This embodiment discloses a Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification, the general formula of which is CoCrFeNi 2 V 0.8 B 0.4 Hypoeutectic alloy composition.

[0029]In this embodiment, the steps of a preparation method of a Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification are as follows: placing an inorganic non-metallic elemental raw material B in a copper crucible in an arc melting furnace At the bottom, the metal elemental raw materials Co, Cr, Fe, Ni and V are covered on top of B. The purity of the selected metal elemental materials is 99.95wt.%, while the purity of inorganic non-metallic materials is 99.99wt.%. The vacuum chamber is evacuated to 3.2×10 -3 pa, and then reversely fill with high-purity argon to -0.05MPa.

[0030] When the alloy ingot is smelted, the current is added to 270A, the smelting time is 110s, and the smelting is repeated 6 times to ensure a uniform structure. Finally, ...

Embodiment 2

[0033] This embodiment discloses a Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification, the general formula of which is CoCrFeNi 2 V 0.94 B 0.47 Fully eutectic high-entropy alloy composition.

[0034] In this embodiment, the steps of a preparation method of a Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification are as follows: placing an inorganic non-metallic elemental raw material B in a copper crucible in an arc melting furnace At the bottom, the metal elemental raw materials Co, Cr, Fe, Ni and V are covered on top of B. The purity of the selected metal elemental materials is 99.95wt.%, while the purity of inorganic non-metallic materials is 99.99wt.%. The vacuum chamber is evacuated to 3.2×10 -3 pa, and then reversely fill with high-purity argon to -0.05MPa.

[0035] When the alloy ingot is smelted, the current is added to 270A, the smelting time is 110s, and the smelting is repeated 6 times to ensure a uniform str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com