Efficient dyeing process for cotton-polyester blended fabric

A cotton-polyester blending and fabric technology is applied in the field of dyeing and finishing technology, which can solve the problems of complicated operation, difficult to wash, influence on fabric fastness, etc., and achieve the effects of improving dyeing efficiency, good color fastness, and efficient dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

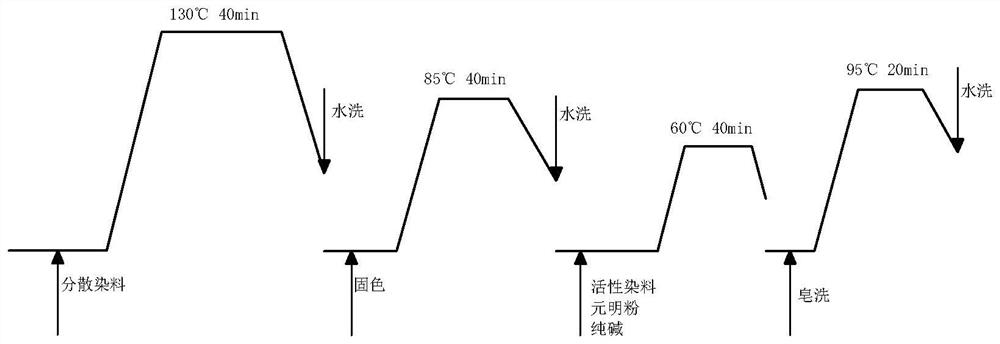

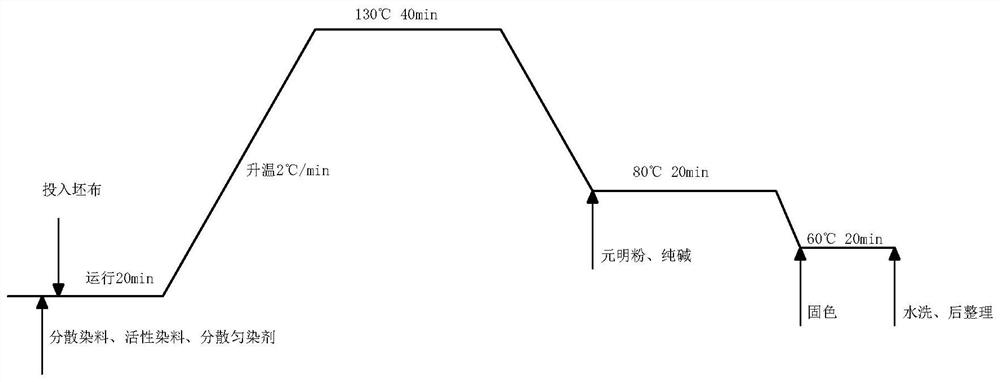

[0044] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0045] A high-efficiency dyeing process for cotton-polyester blended fabrics, comprising the steps of:

[0046] S1 fabric selection, select T / C fabric or CVC fabric as the grey fabric, and check that there is no obvious defect on the surface of the grey fabric, and then pre-type with hot air;

[0047] S2 dye ingredients, according to the type of grey fabric, the dyes are proportioned in turn. The formula of dyes includes:

[0048] Dye mixture 2% owf;

[0049] Soda ash 5g / L;

[0050] Integrating agent 0.5g / L;

[0051] Dispersion and leveling agent 0.5g / L;

[0052] water;

[0053] Among them, the dye mixture includes disperse dyes and reactive dyes. The mass ratio of disperse dyes and reactive dyes is the same as the ratio of polyester to cotton in grey fabrics. Specifically, the ratio of dye mixtures used for dyeing and finishing CVC fabrics is: dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com