Thermal shock resistant solid heat storage device

A solid heat storage and thermal shock resistance technology, applied in the direction of heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of low service life, poor thermal shock resistance and large thermal expansion coefficient of solid heat storage electric heating devices. and other problems, to achieve the effect of reducing heat conduction and heat transfer efficiency, improving thermal shock resistance, and reducing the temperature of the outer surface of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

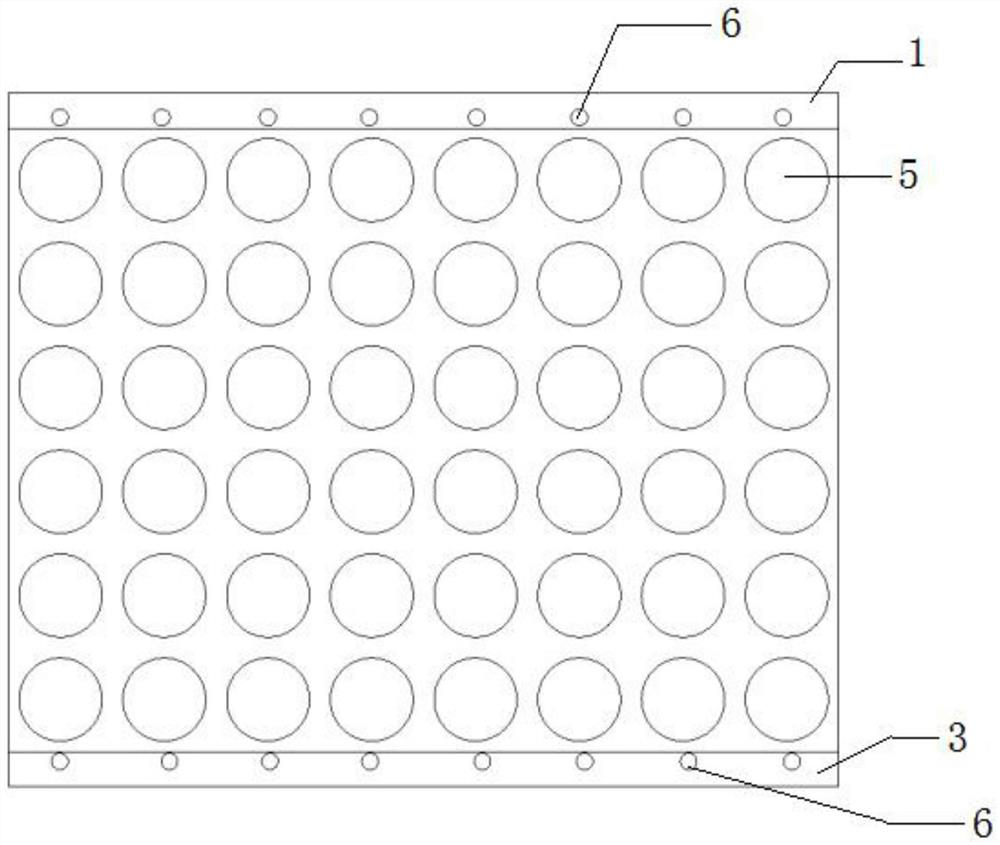

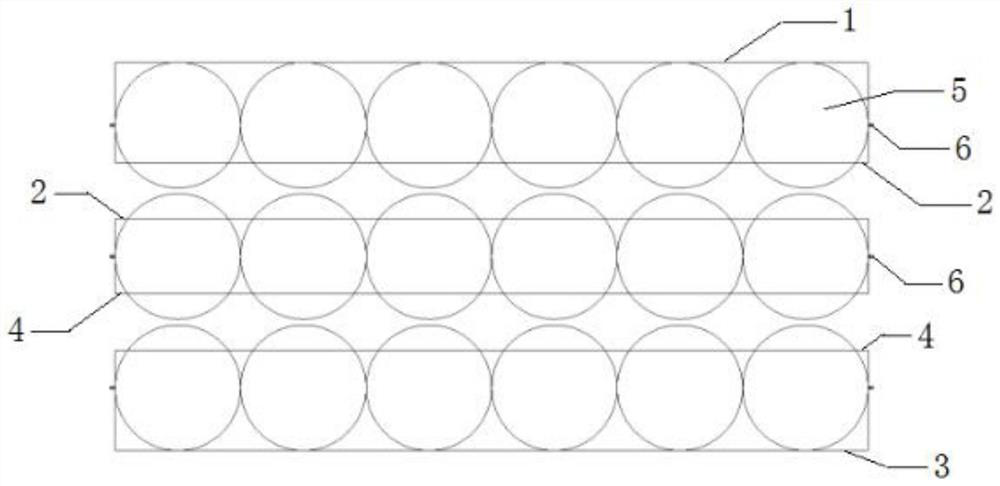

[0029] Embodiment 1: A thermal shock-resistant solid heat storage device in this embodiment sequentially includes an upper end heat storage element, N intermediate heat storage elements and a lower end heat storage element from top to bottom; N is a value of positive integer;

[0030] The upper heat storage element includes an upper positioning base 1, a spherical heat storage body 5, and an upper fixed clip cover 2 in sequence from top to bottom;

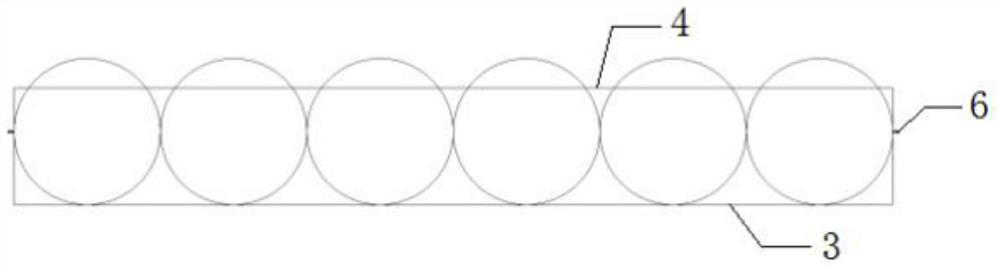

[0031] The lower end heat storage element includes a lower fixed clip cover 4, a spherical heat storage body 5, and a lower positioning base 3 in sequence from top to bottom;

[0032] The intermediate heat storage element includes an upper fixed clip cover 2, a spherical heat storage body 5, and a lower fixed clip cover 4 in sequence from top to bottom;

[0033] The upper positioning base 1 and the upper fixing clip cover 2 are fixedly connected for fixing the spherical heat storage body 5;

[0034] The lower positioning base 3 a...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the upper positioning base 1 and the lower positioning base 3 are thermal insulation fixing bases placed in a high temperature resistant metal base.

[0041] Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the upper fixing clip cover 2 and the lower fixing clip cover 4 are high temperature resistant with circular holes opened according to the size requirements of the spherical regenerator 5, High thermal conductivity metal cover.

[0043] Other steps and parameters are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com