Optical microcavity

An optical microcavity and microcavity technology are applied to the optical microcavity. It can solve the problems of difficult coupling, poor coupling stability, and difficulty in improving quality factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

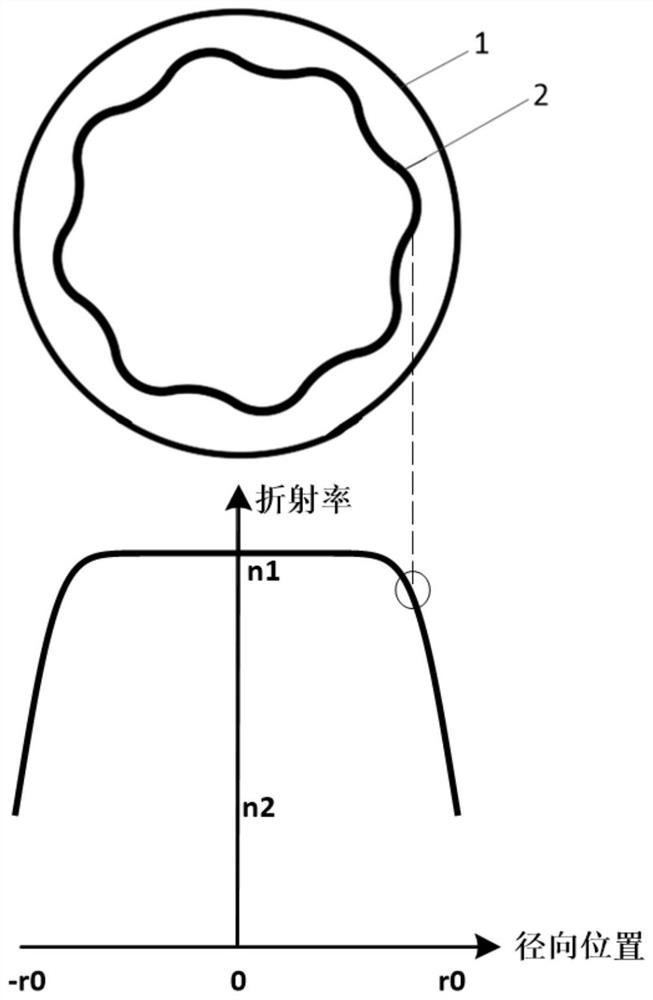

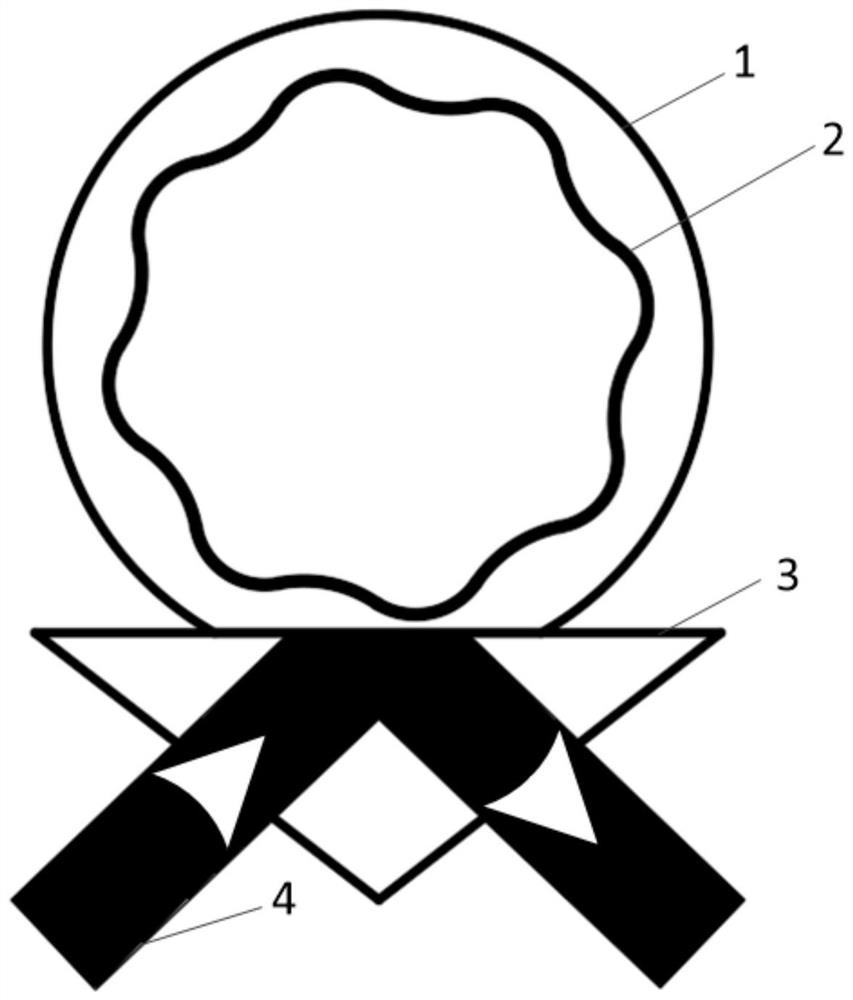

[0039] like figure 1 As shown, the embodiment of the present invention provides an optical microcavity, which is a gradient refractive index microcavity with a continuously changing refractive index along the radial direction, and the gradient refractive index microcavity has a continuously changing gradient refractive index from the inner surface to the outer surface, That is, different positions of the microcavity have different refractive indices. This gradient index microcavity can confine the light field internally, and the entire mode field formed is located inside the microcavity, avoiding the evanescent field of the existing WGM microcavity and the outside world. This kind of gradient index microcavity is not afraid of surface contamination, so it is easier to operate the optical microcavity, and it is convenient for the direct bonding between the optical microcavity and the waveguide to realize Integration of Optical Microcavity and Waveguide Coupling Systems. By des...

Embodiment 2

[0054] The optical microcavity of this embodiment will be described in detail below with reference to the accompanying drawings. figure 1 This is a schematic structural diagram of the optical microcavity of this embodiment, including: a gradient index microcavity having a continuously changing gradient index.

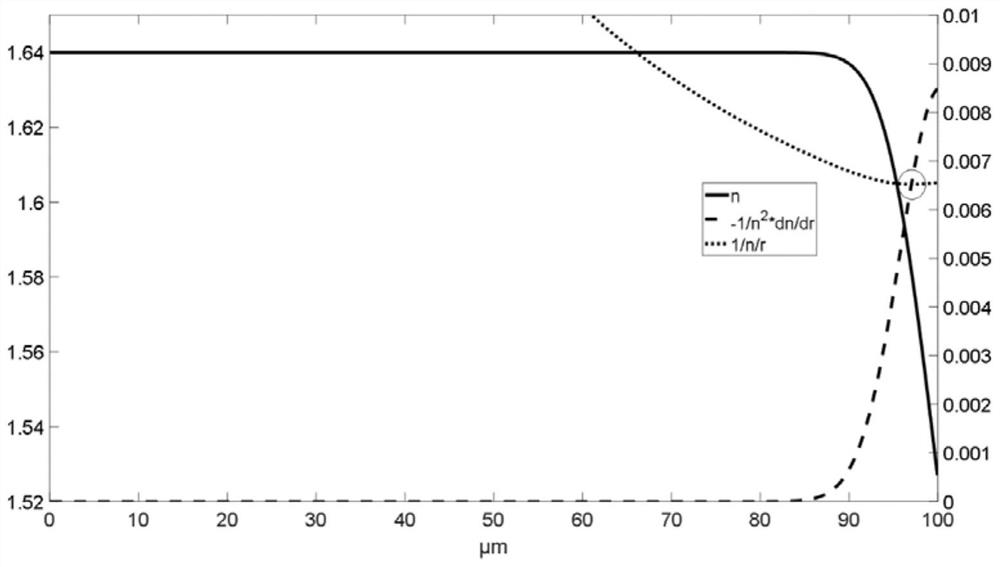

[0055] figure 2 It is the schematic diagram of the radial refractive index distribution and the schematic diagram of the mode field position of the gradient refractive index microcavity of the present invention. In this example, a glass with a radius of 100 μm and a refractive index of 1.64 is used for ion exchange with molten salt, resulting in a central refractive index of 1.64 and a surface refractive index of 1.526, and the refractive index starts to decrease continuously towards the outer surface at a radius of about 87 μm The gradient index microcavity of , the refractive index distribution is shown as the solid line. figure 2 are drawn with dashed and dotted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com