Customized logic engineering design for industrial modular plants

A custom logic, engineering design technology, applied in the direction of comprehensive factory control, comprehensive factory control, manufacturing computing system, etc., can solve problems such as the simplicity and speed of modular automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

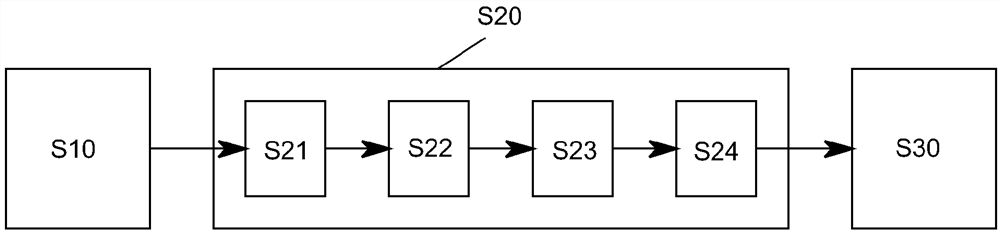

Method used

Image

Examples

Embodiment Construction

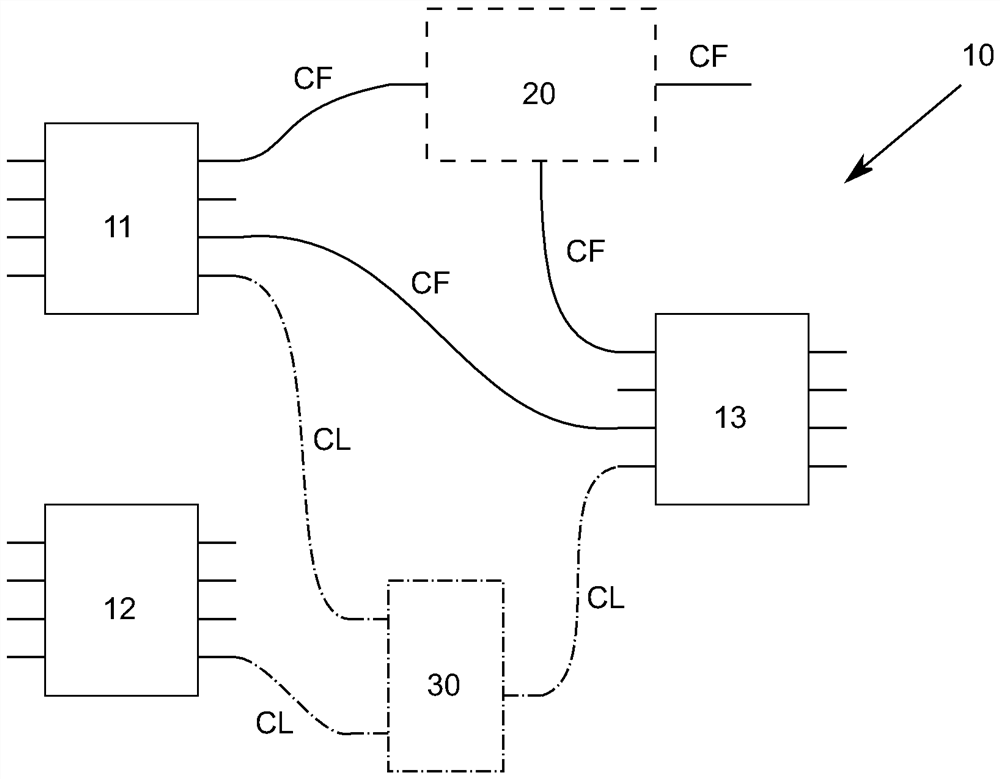

[0081] figure 1 A schematic diagram of a custom process topology 10 according to a first embodiment is shown. The custom process topology 10 relates to an industrial modular plant that will be configured to perform a production process. An industrial modular plant includes at least one physical process module, such as a heating module, a mixing module or a cooling unit. In this case, the industrial modular plant to be controlled or to be designed and controlled includes three physical process modules. The MTP for each physical process module is selected from the database based on the corresponding process data. Therefore, the first MTP 11, the second MTP 12 and the third MTP 13 are selected.

[0082]In addition, for the MTPs 11, 12, 13 corresponding to the physical process modules of the industrial modular plant, two expander units, the first vMTP 20 and the dedicated logic function 30, are selected from the database based on the process data. The vMTP 20 represents the T-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com