Ship ammonia gas treatment system and ship

A treatment system and ammonia gas technology, applied in the field of ships, can solve the problems that cannot be directly applied to ammonia gas discharge treatment, high back pressure at the outlet of hydraulic jet pumps, and affect the efficiency of jet pumps, etc., to achieve small footprint, improve absorption efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

[0027] The terms "first", "second", "third", "fourth", etc. (if present) in the description and claims of the present invention are used to distinguish similar objects and are not necessarily used to describe a particular order or sequence.

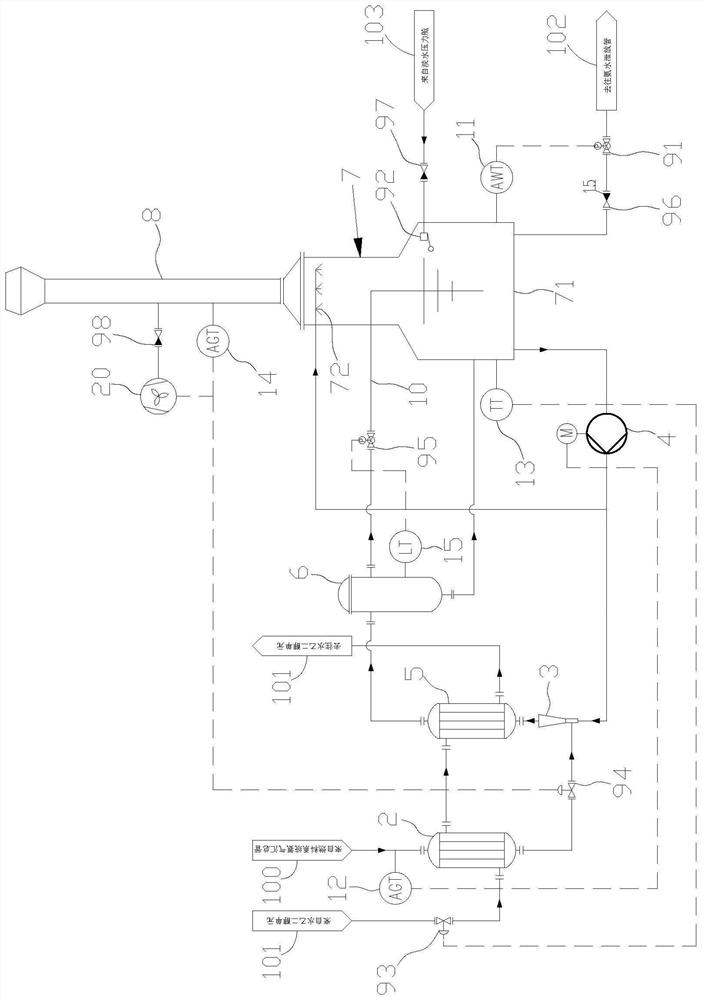

[0028] like figure 1 As shown, the ship ammonia treatment system provided by the embodiment of the present invention includes an ammonia gas collecting pipe 100, a heat exchange unit 101, an ammonia gas heater 2, a hydraulic jet pump 3, an ammonia water circulating pump 4, an ammonia water cooler 5, a gas-liquid Separator 6, absorption tower 7 and ventilation mast 8;

[0029] The ammonia gas collecting pipe 100 from the ammonia fuel supply system is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com